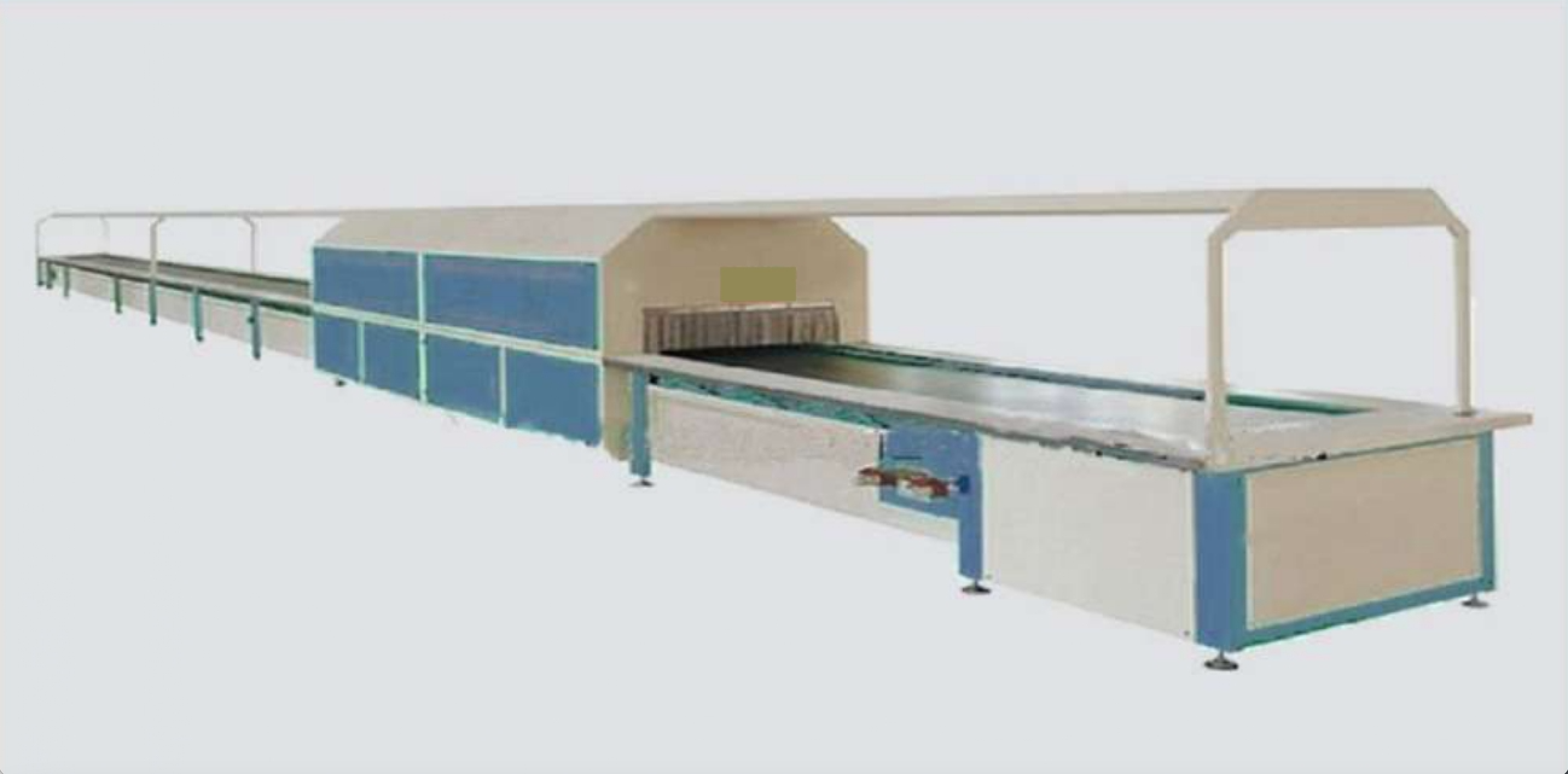

ZY-102 Lasting Conveyor

The ZY-102 Lasting Conveyor is an advanced and robust solution designed to streamline and optimize the shoe lasting process in modern footwear manufacturing environments. Engineered with precision, efficiency, and scalability in mind, the ZY-102 offers an integrated conveyor system that enhances workflow continuity between lasting machines and subsequent production stages, such as sole attachment, stitching, or finishing. In the competitive footwear industry, production speed and product quality are paramount. The ZY-102 lasting conveyor contributes to these goals by providing a reliable, automated transport mechanism for shoe uppers and lasted components, ensuring smooth, timely, and safe material handling while reducing manual labor and associated risks of damage or delays.

Intelligent Conveyor Integration for Lasting Production Lines

The ZY-102 is specifically designed to integrate seamlessly with a variety of lasting machines and production line configurations. It bridges critical operational steps by automatically receiving lasted shoes, securely holding them, and delivering them to the next process stage without human intervention. This automation eliminates bottlenecks, minimizes downtime, and supports continuous production cycles. The conveyor’s design considers the delicate nature of footwear during the lasting process, employing adjustable fixtures and cushioning elements to prevent deformation or surface damage. This ensures that even high-end or complex shoe designs are handled with care, preserving the quality standards expected in today’s fashion and performance markets.

Adjustable and Versatile Conveyor System

One of the core strengths of the ZY-102 lies in its versatile adjustment capabilities, allowing it to accommodate a wide range of shoe sizes, shapes, and styles. This adaptability is essential for modern factories producing multiple models or handling custom orders, where rapid changeovers and flexibility are required. The conveyor width, grip force, and shoe positioning clamps are fully adjustable through mechanical or servo-driven systems, providing secure but gentle handling tailored to the particular footwear being processed. Whether working with delicate women’s fashion shoes or rugged men’s work boots, the ZY-102 maintains consistent transport reliability . This versatility reduces the need for multiple conveyors or manual handling adjustments, simplifying operations and lowering operational costs.

Enhanced Productivity Through Automation

By automating the movement of the last shoes, the ZY-102 significantly increases factory throughput. The conveyor system supports continuous feeding, preventing pileups or wait times between machines, which are common in semi-automated or manual lines. With conveyor speeds that can be precisely controlled and synchronized to match upstream and downstream equipment, the ZY-102 enables a smooth flow that optimizes machine utilization rates. This contributes to improved daily output, meeting growing market demand without the need for additional labor. Its robust build and reliable motor systems allow it to operate at high speeds while maintaining excellent positional accuracy and gentle product handling.

Energy-Efficient and Low-Maintenance Operation

The ZY-102 conveyor is equipped with energy-efficient motors and optimized drive systems that reduce power consumption without compromising performance. Its modular design also facilitates straightforward maintenance, with easily accessible components, quick belt replacement, and user-friendly tension adjustment systems. Regular maintenance is simplified with guided lubrication points and diagnostic indicators that alert operators to potential issues before they escalate. This reduces downtime and extends the service life of the conveyor, providing manufacturers with a durable, cost-effective asset.

Ergonomic and Operator-Friendly Design

To support factory ergonomics and improve operator safety, the ZY-102 features an intuitive design with user-accessible control panels and emergency stop functions within easy reach. The conveyor height and loading zones are designed for comfortable operation, minimizing strain during loading, unloading, and cleaning. Clear visual indicators and simple interface controls enable fast training and reduce human errors, ensuring consistent operation across different shifts and personnel. The system also incorporates safety shields and non-slip surfaces to comply with industrial safety standards, protecting workers while maintaining operational efficiency.

Integration with Modern Smart Factory Systems

The ZY-102 is designed with Industry 4.0 readiness, featuring optional IoT connectivity modules that enable remote monitoring, data collection, and real-time performance analysis. This connectivity allows factory managers to track conveyor speed, operational status, fault conditions, and maintenance schedules via centralized factory management systems. The intelligent feedback loop supports predictive maintenance strategies and continuous improvement initiatives, empowering manufacturers to reduce unplanned downtime and optimize production flows. Through seamless integration with lasting machines and other automated equipment, the ZY-102 becomes an essential component of a smart, interconnected footwear manufacturing environment.

Reliable Handling with Adjustable Clamping and Cushioning

Recognizing the diverse nature of footwear production, the ZY-102 utilizes adjustable clamping mechanisms combined with cushioned support pads that securely hold lasted shoes in place during transit without causing deformation or surface damage. The clamps are designed to accommodate different shoe widths and heel heights, ensuring a firm grip while absorbing shocks or vibrations from conveyor movement. This reduces the risk of shifting, scuffing, or tearing of sensitive upper materials, which is especially important when handling delicate leather, nubuck, or suede. The cushioning materials are wear-resistant and easy to clean, maintaining hygiene standards and prolonging component lifespan.

Comprehensive Technical Specifications and Capacity

The ZY-102 lasting conveyor is engineered for industrial production environments, supporting high throughput capacities with dependable motor systems and control electronics.

-

The conveyor motor is typically rated to deliver consistent power for smooth, continuous operation with adjustable speeds suited to production demands.

-

Conveyor belts are manufactured from durable, heat- and chemical-resistant materials that withstand factory conditions.

-

Dimensions and conveyor length options are configurable to match different production line layouts.

-

Safety and control components comply with international industrial machinery standards.

With such robust specifications, the ZY-102 maintains productivity levels even under intense multi-shift production scenarios, supporting factories in achieving output targets consistently.

Easy Installation and Customization Options

The ZY-102 can be customized to meet specific production needs, including length adjustments, belt material options, clamp configurations, and interface compatibility with a variety of lasting machine brands and models. Installation is designed to be straightforward with modular components and adjustable supports that fit existing factory infrastructure without requiring significant remodeling. The manufacturer offers technical support and installation assistance to ensure smooth deployment. Optional accessories such as integrated sensors, automatic shoe detection, or auxiliary feeding stations further enhance the conveyor’s flexibility and automation capabilities.

Application Scenarios Across Footwear Manufacturing

The ZY-102 lasting conveyor is widely applicable across various footwear production stages and styles:

-

In athletic shoe production, it efficiently transports the last uppers for sole attachment or finishing.

-

For dress and casual shoes, it ensures delicate materials are handled without damage while speeding up production.

-

In safety footwear and work boots, it supports heavy-duty lasted shoes with a strong grip and reliable traction.

-

The conveyor is also well-suited for custom footwear workshops, where varying shoe models require quick adjustment and smooth product flow.

Its versatility and reliability make it an essential component of both high-volume and bespoke manufacturing lines.

Operational Benefits and Cost Savings

Implementing the ZY-102 lasting conveyor provides manufacturers with multiple operational advantages:

-

Reduced labor costs by automating the shoe transfer between lasting and subsequent operations.

-

Minimized product damage due to gentle handling and secure clamping.

-

Increased machine uptime by eliminating manual delays and smoothing production flow.

-

Faster changeovers thanks to adjustable settings and memory presets.

-

Lower maintenance expenses through durable materials and easy access components.

-

Improved workplace safety with integrated safety features and ergonomic design.

Together, these benefits contribute to enhanced factory profitability and a competitive edge in the fast-evolving footwear market.

The ZY-102 Lasting Conveyor is a critical automation solution for modern footwear manufacturers seeking to optimize their production lines. Its combination of versatility, precision handling, advanced automation, and energy-efficient operation makes it a valuable asset for enhancing production efficiency and product quality. By seamlessly integrating with lasting machines and supporting smart factory ecosystems, the ZY-102 helps manufacturers reduce labor dependency, improve throughput, and ensure consistent quality across diverse shoe styles and materials . Whether in a large-scale industrial plant or a specialized custom shop, the ZY-102 lasting conveyor provides the reliability, flexibility, and operational excellence needed to stay competitive in today’s demanding footwear industry.

No posts found