AUTOMATIC HYDRAULIC TOE LASTING MACHINE TW- 587A/C/CD/CM

MACHINE NAME: AUTOMATIC HYDRAULIC TOE LASTING MACHINE

MODEL NO: TW- 587A/C/CD/CM

BRAND: TAIWEI

FEATURES

Fully hydraulic operation system and high-low voltage circuit designing, the hydraulic system pressure and speed control located outside of machine easier monitoring and adjusting, stable operating system. Back and forth adjustment of internal and external of last support according to various type of shoes size quick to adjust the relative position between last support and middle pincer.(maximum 10 mm)

USE AND CHARACTERISTICS

Fully hydraulic operation system and high-low voltage circuit designing, the hydraulic system pressure and speed control located outside of machine easier monitoring and adjusting, stable operating system. Back and forth adjustment of internal and external of last support according to various type of shoes size quick to adjust the relative position between last support and middle pincer.(maximum 10 mm) The free adjustment design of toe head pressing stroke supplies firm pressing force, none effect causing by oil temperature or different pressure. All-around forming band and specially tracked wipers with direct heating system ensure uppers more evenly and closely attached to last after lasting, the surface becomes more beautiful and quality upgraded. Excellent forming band removing system effectively reduce the replacing time. Unique middle pincer and second pincer quick changing equipment, changing the pincers quickly without any tools. The conjunction angle between the middle and second pincer(each side)can be up to 20 degree, suitable for quick changing shoes shape.(TW-587CD, TW 587CM) The size of shoe adjustment in pincer plate is independently, quickly and accurately. The machine is equipped with auxiliary wiper mechanism and toe position projector. All-around forming hand and specially tracked wipers ensure upper attached to the last closely and evenly after lasting. The fifth pincer automatic rotary movement increases the lasting perfection of inner part. (TW-587C. TW-587CD. TW-587CM)

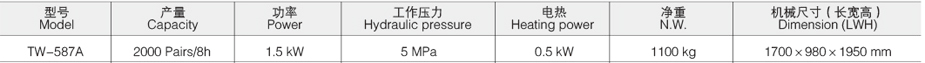

TECHNICAL PARAMETER

The TW-587A/C/CD/CM Automatic Hydraulic Toe Lasting Machine represents a pinnacle of innovation and efficiency in the shoe manufacturing industry. Designed for high-performance lasting operations, this machine integrates fully hydraulic systems with intelligent control features to streamline the shoe toe lasting process. It is specially engineered to deliver consistent, high-quality lasting results while reducing operator fatigue and improving productivity. The TW-587 series machines are the culmination of advanced engineering, combining precision mechanics, hydraulic power, and user-friendly automation. Their robust construction, versatile adjustments, and sophisticated control systems make them ideal for handling various shoe styles, materials, and sizes with ease. Whether in small-scale workshops or large industrial production lines, the TW-587 series enhances lasting accuracy and overall shoe quality.

Fully Hydraulic Operation System & High-Low Voltage Circuit Design

At the heart of the TW-587 series lies a fully hydraulic operation system complemented by a sophisticated high-low voltage circuit design. This design philosophy ensures reliable performance, smooth motion, and precise control across all operational stages.

-

Hydraulic System Pressure and Speed Control Located Outside the Machine: This external placement of the hydraulic control panel allows operators and maintenance personnel to monitor and adjust system pressure and speed with ease, without interrupting production or opening machine covers.

-

Stable Operating System: The hydraulic system is engineered for consistent pressure delivery and speed modulation, ensuring stable and repeatable lasting operations even under demanding conditions.

-

Energy Efficiency and Safety: High-low voltage circuit design optimizes electrical power usage and enhances system safety by segregating high power components from control circuits.

Adjustable Back and Forth Movement of Last Support

The TW-587 series includes an intelligent mechanism for the back and forth adjustment of both internal and external parts of the last support. This feature is critical for adapting to various shoe sizes and types.

-

Quick Adjustment of Relative Position Between Last Support and Middle Pincer: Operators can easily modify the gap up to a maximum of 10 mm, allowing for perfect alignment tailored to different shoe lasts.

-

Enhanced Versatility: Accommodates diverse shoe shapes and sizes without requiring extensive manual repositioning or complex setup procedures.

-

Improved Lasting Accuracy: Fine-tuning the relative positioning ensures the shoe upper is pulled and held firmly during the lasting process, reducing deformation or material stress.

Free Adjustment Design of Toe Head Pressing Stroke

The machine’s toe head pressing stroke features a free adjustment design, providing a firm, consistent pressing force unaffected by oil temperature fluctuations or pressure variations in the hydraulic system.

-

Stable Pressing Force: Guarantees consistent pressure regardless of ambient temperature changes or hydraulic fluid condition, crucial for uniform lasting quality.

-

Durability and Reliability: Eliminates the common issue of variable force due to oil viscosity changes, leading to fewer defects and less wear on machine components.

-

Smooth Operation: Prevents jerky or inconsistent pressing, preserving the integrity of delicate upper materials.

All-Around Forming Band and Specially Tracked Wipers with Direct Heating System

One of the machine’s standout features is its all-around forming band and specially tracked wipers integrated with a direct heating system.

-

Even and Close Attachment of Uppers to Last After Lasting: The forming band wraps the shoe upper uniformly, while the heated wipers soften and press the material, ensuring perfect adhesion and shaping.

-

Enhanced Aesthetic Quality: The heated, even pressure results in smoother upper surfaces with improved visual appeal and tactile feel.

-

Upgraded Shoe Quality: Properly formed uppers reduce wrinkles, creases, and loose spots, increasing durability and customer satisfaction.

Excellent Forming Band Removing System

To maximize production efficiency, the TW-587 machines feature an excellent forming band removal system that dramatically reduces the time needed to replace the forming band.

-

Fast and Simple Band Changes: Minimizes downtime between production runs or when changing shoe models.

-

Operator-Friendly: Designed for quick, tool-free operation, facilitating easy maintenance.

-

Improved Workflow: Enables continuous production with minimal interruptions, boosting overall throughput.

Unique Middle Pincer and Second Pincer Quick Changing Equipment

Flexibility in handling different shoe styles is enhanced by the unique quick-changing system for the middle and second pincers.

-

Tool-Free Pincer Replacement: Operators can swap pincers rapidly without the need for wrenches or specialized tools.

-

Time Savings: Quick changeovers enable fast adaptation to new shoe models or sizes, critical in dynamic production environments.

-

Reduced Setup Errors: The design ensures pincers are correctly positioned every time, eliminating setup mistakes.

-

Compatibility: Designed to accommodate a wide variety of pincers tailored to specific lasting tasks.

Adjustable Conjunction Angle Between Middle and Second Pincer

The TW-587CD and TW-587CM variants include a conjunction angle between the middle and second pincer (each side) adjustable up to 20 degrees.

-

Enhanced Shoe Shape Adaptability: This adjustability allows the machine to quickly conform to different shoe toe shapes and styles.

-

Better Material Handling: Ensures pincers grip and hold the upper material optimally without damaging or overstretching.

-

Improved Lasting Accuracy: The adjustable angle contributes to a more natural, anatomical shoe shape.

-

Operational Flexibility: Particularly useful for manufacturers producing a wide range of footwear styles with varying last geometries.

Independent, Quick, and Accurate Shoe Size Adjustment on Pincer Plate

Precision control extends to the independent adjustment of shoe size on the pincer plate.

-

Fast, Accurate Adjustments: Operators can quickly set the pincer plate to the desired shoe size, ensuring precise material gripping.

-

Customization: Accommodates different shoe sizes without the need for replacing components or extensive recalibration.

-

Consistent Production Quality: Maintains repeatability and reduces errors caused by size mismatch.

Auxiliary Wiper Mechanism and Toe Position Projector

To further enhance the quality and precision of the lasting process, the machine is equipped with an auxiliary wiper mechanism and a toe position projector.

-

Auxiliary Wiper Mechanism: Provides additional pressure and smoothing action to critical upper areas, preventing wrinkles and improving the overall shoe appearance.

-

Toe Position Projector: Projects a precise indicator onto the toe area, guiding operators during setup and ensuring the upper is aligned perfectly relative to the last.

-

Improved Accuracy and Efficiency: Operators can position materials more quickly and with higher confidence, reducing setup times and defects.

All-Around Forming Hand and Specially Tracked Wipers

Similar to the forming band system, the all-around forming hand combined with specially tracked wipers ensures the shoe upper is tightly and evenly attached to the last.

-

Uniform Pressure Distribution: Avoids material displacement and creasing.

-

Enhanced Lasting Perfection: Results in superior final shoe quality and longevity.

-

Ideal for Complex Upper Designs: Handles intricate shoe uppers with multiple panels and seams effectively.

Fifth Pincer Automatic Rotary Movement (TW-587C, TW-587CD, TW-587CM)

An advanced feature in the TW-587C, TW-587CD, and TW-587CM models is the fifth pincer automatic rotary movement, which greatly improves the lasting perfection of the shoe’s inner parts.

-

Rotary Action: Automatically rotates the fifth pincer during lasting to apply consistent pressure around the shoe inner toe box.

-

Increased Lasting Precision: Ensures tight, wrinkle-free inner surfaces, crucial for shoe comfort and durability.

-

Automated Process: Reduces manual labor and variability.

-

Enhanced Production Consistency: Minimizes defects related to inner toe shaping.

Knife Trend Setting and Grinding Unit

The TW-587 series includes a grinding unit that is compatible with corundum or diamond grinding wheels, offering superior blade maintenance capabilities.

-

No Need for Knife Trend Setting: Simplifies blade preparation by automating alignment and sharpening.

-

Single Micrometric Grinding Control: Enables precise sharpening adjustments, restoring blade edges with high accuracy.

-

Flexible Blade Width Setting: Quickly adapts to different blade sizes for various cutting tasks.

-

Energy Efficient: Independent motor control reduces power consumption by activating grinding only when needed.

-

Dust and Scrap Cleaner: An independent cleaning unit ensures the blade remains free from debris, maintaining cutting efficiency.

Advanced Operational Controls

The TW-587A/C/CD/CM machines boast a variety of operational controls and features designed to streamline production:

-

Automatic Blade Set Adjustment: Keeps blades correctly positioned throughout use.

-

Precise Linear Bearing Guide for Grinding Wheel Movement: Ensures smooth, consistent blade sharpening.

-

Digital Thickness Display: Shows splitting thickness with high precision for quality control.

-

Non-Level Adjustable Feeding Speed with Auto Toe Split: Adapts to material characteristics to ensure clean splits.

-

Fast Pressure Adjustment: Allows operators to rapidly change working pressure to match different materials.

-

Optical Viewer for Blade Symmetry: Provides real-time visual inspection to detect blade wear or misalignment.

-

Quick Guide Roll Replacement Without Joint Removal: Simplifies maintenance tasks, minimizing downtime.

-

Ergonomic Work Position: Reduces operator fatigue and improves safety.

-

Life-Lubricated Mechanical Components: Require minimal maintenance and reduce wear.

-

Low Noise Level (<70 dB): Creates a comfortable working environment.

-

Safety Devices Compliant with CE Standards: Ensure operator protection and machine reliability.

Ease of Maintenance and Service

The design of the TW-587 series emphasizes easy access to all components for quick servicing and maintenance:

-

Rapid servicing reduces downtime and helps maintain continuous production flow.

-

Comprehensive instruction manuals and included maintenance tools support operators in performing routine checks and repairs effectively.

-

Robust build quality and life-lubricated parts reduce the frequency of required interventions, lowering operational costs.

Industry Applications

The TW-587 series is ideal for a wide range of footwear production scenarios:

-

Casual, Formal, and Sports Shoes: Compatible with leather, synthetic, and composite uppers.

-

Mass Production Lines: Suitable for high-volume manufacturing with rapid changeover needs.

-

Custom and Specialty Footwear: Accommodates unique shoe lasts and customized sizing.

-

Leather Goods Manufacturers: Useful for precision forming in bags, gloves, and accessories where lasting is involved.

The TW-587A/C/CD/CM Automatic Hydraulic Toe Lasting Machine delivers a comprehensive solution for modern footwear manufacturers demanding high quality, operational flexibility, and efficient production workflows. Its combination of fully hydraulic control, advanced pincer systems, precise adjustments, and ergonomic design make it a standout in the competitive shoe lasting equipment market.

By investing in the TW-587 series, manufacturers can expect:

-

Enhanced Product Quality: Perfectly lasted shoes with uniform uppers and wrinkle-free surfaces.

-

Improved Production Efficiency: Quick setups, tool-free pincer changes, and fast band replacement reduce downtime.

-

Operator Comfort and Safety: Thoughtful ergonomics and CE-certified safety systems protect personnel.

-

Cost Savings: Energy-efficient systems and low maintenance requirements reduce operating expenses.

The TW-587 series exemplifies how advanced machinery can elevate traditional shoe making to a new standard of precision, reliability, and productivity.

No posts found