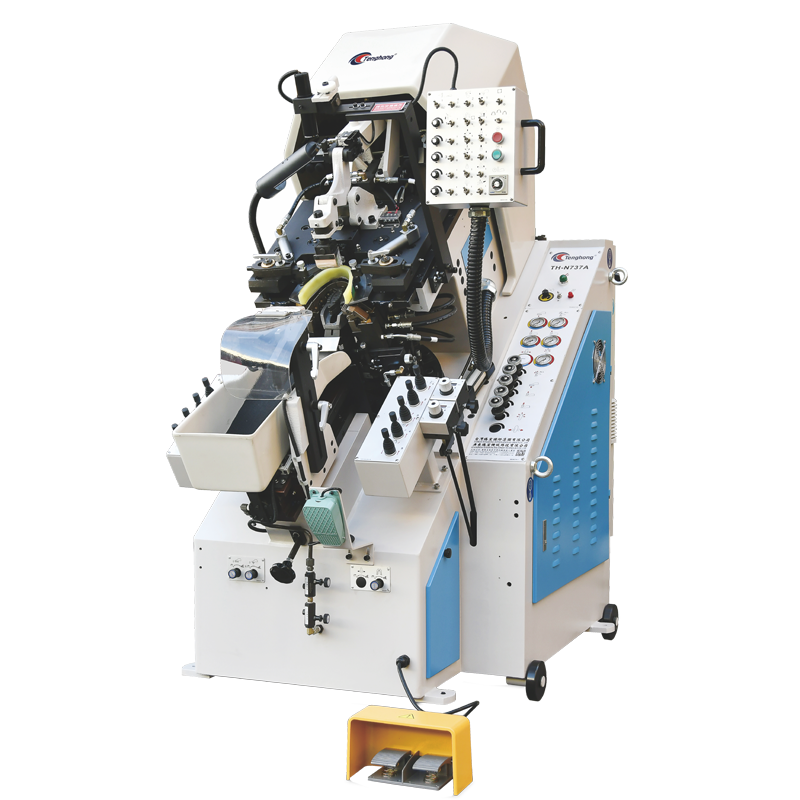

9 PINCERS HYDRAULIC AUTOMATIC TOE LASTING MACHINE TH-N737A

MACHINE NAME: 9 PINCERS HYDRAULIC AUTOMATIC TOE LASTING MACHINE

MODEL NO: TH-N737A

BRAND: TENGHONG

FEATURES

- Fully hydraulic operated system.

- The rising stop point and the drafting stop point of the newly designed last supporter are adjusted speedily and externally, accompanied by the digitized position indication up to 0.1mm, which is the most accurate repeat ability.

- The centralized control of selection and function switches make the operation more convenient.

- The machine can be installed additionally with the auxiliary binder and wiper body depending needs.

- The middle pincer can be adjusted for yawing to be left and to the right within 15 each side according to the toe cap shape suitable for special shoe models and pincers assembly arrangement.

- The fifth pincer has the function of inward rotation the rotation angle adjustment is depending on the demands and enabling the shoe more fit the shoe last when lasting.

- The machine is accompanied with the align light device to filletable the toe cap correction and position.

TECHNICAL PARAMETER

- Pincers : 9

- Capacity : 1600 pairs/8H

- Power : 3HP

- Net weight : 1175kg

- Oil pressure : 50kg/cm2

- Heating Power : 1kw

- Oil Filling : 115 liters

- Gross weight : Be provided before shipment.

- Dimension : 1750(L)x980(W)x1950mm(H)

- Packing size : 1860(L)x1030(W)x2160mm(H)

The TH-N737A 9 Pincers Hydraulic Automatic Toe Lasting Machine is a state-of-the-art solution designed to enhance efficiency, precision, and adaptability in the shoe manufacturing process. Its fully hydraulic operation system ensures consistent performance, making it an ideal choice for manufacturers aiming for high-quality output and streamlined operations.

Fully Hydraulic Operation System

At the heart of the TH-N737A is its fully hydraulic operation system, which provides stable and consistent pressure throughout the lasting process. >span class=relative -mx-px my-[-0.2rem] rounded px-px py-[0.2rem] transition-colors duration-100 ease-in-out>The hydraulic mechanism also contributes to the machine's durability and low maintenance requirements, making it a reliable asset in high-volume production environments.

Advanced Pincer Mechanism

>span class=relative -mx-px my-[-0.2rem] rounded px-px py-[0.2rem] transition-colors duration-100 ease-in-out

Adjustable Last Support

>span class=relative -mx-px my-[-0.2rem] rounded px-px py-[0.2rem] transition-colors duration-100 ease-in-out

Versatile Applicator Width Adjustment

To accommodate various shoe sizes, the width of the applicator can be quickly adjusted. >span class=relative -mx-px my-[-0.2rem] rounded px-px py-[0.2rem] transition-colors duration-100 ease-in-out>The quick adjustment capability reduces downtime when switching between different shoe sizes, increasing overall production efficiency.

Dual-Stage Toe Pusher Mechanism

>span class=relative -mx-px my-[-0.2rem] rounded px-px py-[0.2rem] transition-colors duration-100 ease-in-out>During the initial pressure application, operators can choose between pressure-controlled or position-controlled modes to achieve the best operation for different shoe types. >span class=ms-1 inline-flex max-w-full items-center relative top-[-0.094rem] animate-[show_150ms_ease-in]>

Variable Speed Wiper Movement

>span class=relative -mx-px my-[-0.2rem] rounded px-px py-[0.2rem] transition-colors duration-100 ease-in-out

Standard Auxiliary Mechanisms

The TH-N737A comes equipped with several standard auxiliary mechanisms to enhance its functionality:

-

Auxiliary Wiper Mechanism: Ensures even distribution of glue across the insole, contributing to a strong bond between the upper and the sole.

-

Auxiliary Side Pusher Mechanism: Provides additional support during the lasting process, ensuring the upper material conforms accurately to the last.

-

Toe Projector Mechanism: Assists in the precise positioning of the toe area, enhancing the accuracy of the lasting process.

Technical Specifications

-

Model: TH-N737A

-

Dimensions (L×W×H): 980 × 1750 × 1950 mm

-

Packing Size (L×W×H): 1030 × 1860 × 2160 mm

-

Weight: 1160 kg

-

Production Capacity: 1600 pairs per 8 hours

-

Power: 2.7 kW

-

Voltage: 380V

>span class=relative -mx-px my-[-0.2rem] rounded px-px py-[0.2rem] transition-colors duration-100 ease-in-out>Its combination of advanced hydraulic systems, adjustable components, and auxiliary mechanisms ensures high-quality production with minimal downtime. Whether dealing with various shoe sizes, materials, or designs, this machine offers the flexibility and precision required to meet the demands of today's footwear industry.

No posts found