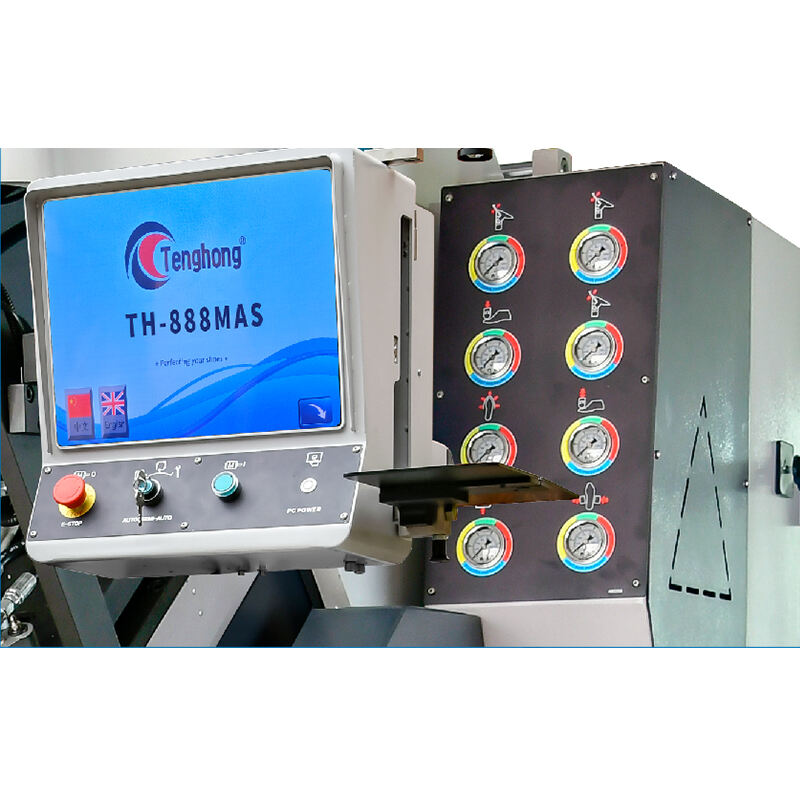

COMPUTER MEMORY VISUAL LOCUS FULLY SERVO CONTROL CEMENTING TOE LASTING MACHINE TH-888MAS

MACHINE NAME: COMPUTER MEMORY VISUAL LOCUS FULLY SERVO CONTROL CEMENTING TOE LASTING MACHINE

MODEL NO: TH-888MAS

BRAND: TENGHONG

FEATURES

●No glue tray toe lasting machine, equipped with visual locus five-axis servo adhesive pen feeding .

method, saves time and cost of replacing the glue gray, and with the servo feeding function can reduce the adhesive overflow, achieve perfect lasting effect on bonding for pointed-toe women’s shoes, soft midsoles, and thinner midsoles.

●Save time: No glue tray design allows for quick change of shoe types, increasing machine uptime and improving production efficiency.

●Save labor: The precise servo trajectory adhesive, reducing overflow issues and eliminating the need for additional personnel to remove adhesive in shoe factories.

●Save costs: Using servo trajectory adhesive can prevent adhesive dripping from the adhesive plate, reducing waste of adhesive

●Fully intelligent: Shoe type settings are fully memorized, allowing for quick changes of shoe types, and equipped with IOT networking (optional).

TECHNICAL PARAMETER

- Power : 2Kw

- Oil pressure : 50Kg/Cm2

- Productivity : 1440pairs/8H

- Oil filling : 136 L

- Dimension : 1930(L)x1180(W)x1915(H)mm

- Packing Size : 2050(L)x2330(W)x 2125(H)mm

The TH-888MAS is a state-of-the-art, fully servo-controlled cementing toe lasting machine designed for modern shoe manufacturing environments demanding high precision, efficiency, and adaptability. This machine integrates the latest servo motor technology with intelligent control systems and visual locus guidance to revolutionize the toe lasting process, especially for challenging shoe designs such as pointed-toe women’s shoes, soft midsoles, and thinner midsoles. The TH-888MAS eliminates the need for a traditional glue tray, instead utilizing an advanced five-axis servo adhesive pen feeding system that dramatically reduces adhesive waste, prevents overflow, and ensures a superior lasting quality. With a robust construction and fully computerized memory control, it provides shoe manufacturers with unmatched operational flexibility, cost savings, and production throughput.

Key Features and Detailed Description

No Glue Tray Toe Lasting Machine

The TH-888MAS innovatively dispenses with the conventional glue tray used in lasting machines. Traditional glue trays often require frequent replacement and cleaning, which increases downtime and operational costs. The absence of a glue tray in this model facilitates:

-

Reduced Maintenance: No trays to clean or replace, which translates into lower maintenance requirements and less machine downtime.

-

Enhanced Production Speed: Operators can switch shoe types rapidly without waiting for glue tray adjustments, increasing overall production line uptime.

-

Cleaner Working Environment: By avoiding glue trays, the machine reduces glue spillage and contamination in the production area, contributing to a safer and tidier factory floor.

Visual Locus Five-Axis Servo Adhesive Pen Feeding Method

This is a standout feature of the TH-888MAS. The machine employs a highly precise five-axis servo motor system to control an adhesive pen that applies glue directly and accurately along the shoe toe lasting area.

-

Visual Locus Technology: This advanced guidance system ensures that the adhesive application follows the exact contour and shape of the shoe toe, particularly beneficial for pointed-toe designs and intricate shoe lasts.

-

Five-Axis Movement: Allows multidimensional control, ensuring that the adhesive is applied evenly and precisely without any gaps or excessive overlaps.

-

Servo Control: Ensures consistent feeding speed and pressure of adhesive, preventing both under-application and overflow.

The result is a perfect lasting effect with excellent bonding strength, especially critical in footwear with delicate or thin midsole materials.

Time Saving and Increased Efficiency

The elimination of the glue tray, combined with intelligent servo feeding technology, delivers significant time savings:

-

Quick Shoe Type Changes: Shoe lasts of various shapes and sizes can be processed with minimal machine adjustment time, as shoe parameters are stored and easily retrieved from memory.

-

Reduced Downtime: Without glue tray changes and cleaning, the machine stays in operation longer, contributing to higher productivity rates.

-

Enhanced Cycle Time: The precise glue application means fewer defects and rework, further accelerating production cycles.

Labor Saving

In traditional lasting machines, manual intervention is often needed to manage glue overflow and clean the glue tray or surrounding components. The TH-888MAS reduces labor requirements by:

-

Minimizing Adhesive Overflow: Servo control ensures glue is applied only where needed, preventing spillover.

-

Reducing Cleanup Efforts: Less glue waste means fewer stops to clean and maintain the equipment.

-

Lowering Manual Touchpoints: The automatic control of glue application decreases the need for human supervision during the lasting process.

Cost Saving through Efficient Adhesive Use

Glue is a significant recurring cost in shoe manufacturing. By utilizing servo trajectory adhesive application, the TH-888MAS reduces waste significantly:

-

Prevention of Dripping: Unlike tray-based machines, there is no dripping or excess glue falling from the glue plate.

-

Optimal Adhesive Consumption: Precise application ensures the exact required amount of adhesive is used, avoiding excess consumption.

-

Reduced Waste Disposal Costs: Less leftover glue means lower disposal costs and a more eco-friendly production process.

Fully Intelligent Shoe Type Settings with Computer Memory Control

The TH-888MAS incorporates a sophisticated PLC (Programmable Logic Controller) system with:

-

Extensive Memory Capacity: The machine can store comprehensive settings for up to 500 groups of shoe types, including lasting parameters and pincer locations.

-

Fast Recall: Operators can select pre-stored programs for different shoe models, facilitating fast changeovers without manual reconfiguration.

-

Parameter Customization: Stroke length, adhesive timing, and pincer actions can be easily adjusted and saved for repeatability.

-

Key Switch Protection: To prevent unauthorized or accidental changes to critical settings, the system is equipped with a key switch lock.

This intelligent memory control enhances operational stability and efficiency, reducing errors and ensuring consistent quality.

IoT Networking Capabilities (Optional)

To meet the demands of Industry 4.0 and smart factories, the TH-888MAS can be equipped with optional Internet of Things (IoT) connectivity features:

-

Real-Time Monitoring: Supervisors can track machine status, production counts, and error diagnostics remotely.

-

Data Logging and Analysis: Historical production data can be stored and analyzed to optimize workflow and maintenance scheduling.

-

Predictive Maintenance: Alerts can be set up for preventive maintenance based on machine usage and performance metrics.

-

Integration with Factory Systems: The machine can communicate with other equipment and central management systems to enhance coordination and overall production efficiency.

Technical Specifications

>td >Number of Pincers

| Specification | Details |

|---|---|

| Model | |

| 9 | |

| Power | 3HP |

| Heating Power | 2kw |

| Oil Pressure | 50 kg/cm² |

| Productivity | 1440 pairs per 8 hours |

| Oil Filling Capacity | 136 liters |

| Dimensions (L x W x H) | 1930 mm x 1180 mm x 1915 mm |

| Packing Size (L x W x H) | 2050 mm x 2330 mm x 2125 mm |

In-Depth Explanation of Machine Components and Operations

Servo Control System

The core of the TH-888MAS’s precision lies in its servo motor-driven components. Unlike traditional pneumatic or hydraulic systems, servo motors provide:

-

High Precision Control: Accurate positioning and speed control of adhesive pen movement.

-

Responsive Adjustments: Instantaneous changes in movement speed and direction according to programmed shoe lasting parameters.

-

Energy Efficiency: Servo motors consume power only when in motion, reducing overall energy use.

-

Durability and Reliability: Minimal wear compared to mechanical or pneumatic systems, resulting in lower maintenance costs.

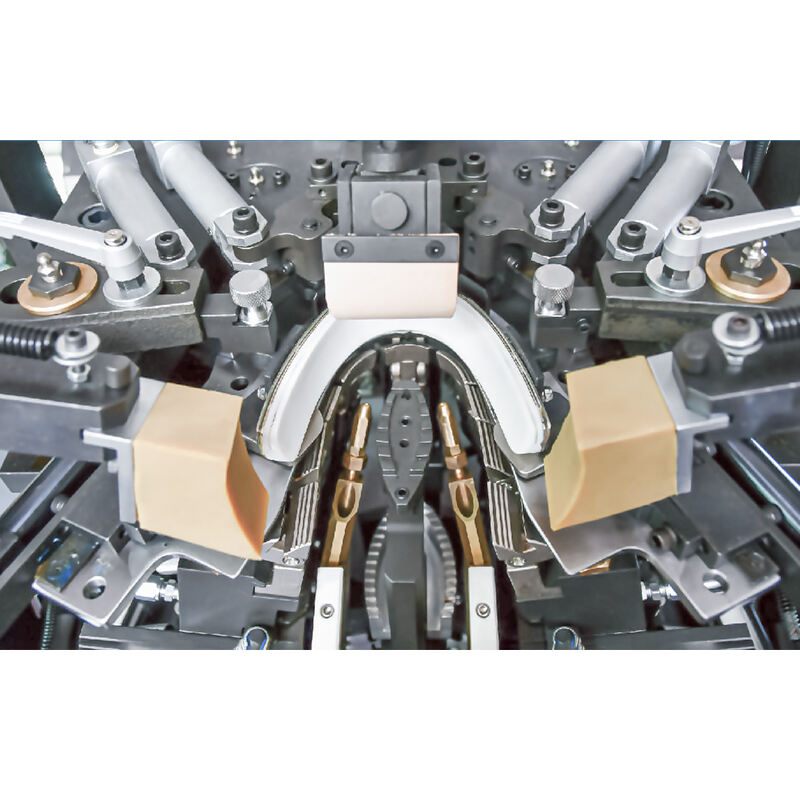

Five-Axis Adhesive Pen Movement

The adhesive pen on the TH-888MAS moves in a complex five-axis pattern, controlled precisely by the servo system:

-

Axes Include: Forward/backward, up/down, left/right, rotational yaw, and tilt pitch.

-

Benefits: This allows the adhesive application to contour perfectly to the shoe’s toe shape, especially important for non-standard shapes such as pointed toes and asymmetrical designs.

-

Outcome: Uniform adhesive application without bubbles, gaps, or excess buildup that could compromise bonding or shoe aesthetics.

No Glue Tray Design

Traditional lasting machines often rely on glue trays where the shoe sole is dipped or adhesive is manually applied. The TH-888MAS’s glue tray-free design allows:

-

On-Demand Adhesive Application: Glue is applied precisely where needed with no pooling or dripping.

-

Faster Setup and Cleaning: The absence of glue trays means less downtime between shoe models or production batches.

-

Environmental and Cost Benefits: Less adhesive wasted means lower environmental impact and cost savings on materials.

User-Friendly Touchscreen Interface

The TH-888MAS features an intuitive PLC touch screen graphic display allowing operators to:

-

Set Parameters Easily: Stroke lengths, glue application time, pincer clamping force, and other critical settings.

-

View Real-Time Data: Monitor the current shoe type program, adhesive application status, and machine diagnostics.

-

Error Diagnostics: Quickly identify and troubleshoot problems with the help of on-screen error messages, reducing downtime.

-

Data Input via Keypad: Allows fast parameter entry and adjustment without complex manual controls.

Pincer Configuration and Adjustment

The machine comes with 9 pincers, each independently controlled:

-

Automated Pull-Down Stroke: Adjusts tension on the vamp automatically for perfect lasting balance.

-

Manual Clamping and Release: Operators can intervene as necessary to control holding force and positioning.

-

Precise Positioning: Pincers can be fine-tuned electronically to match specific shoe lasts, ensuring consistency.

Oil Pressure Operation System

-

The TH-888MAS operates on a fully oil-pressure system rated at 50 kg/cm².

-

Advantages: Stable and consistent force application, reducing mechanical wear and increasing precision.

-

Oil Tank Capacity: 136 liters to ensure smooth hydraulic operations with minimal maintenance interruptions.

Heating Power and Temperature Control

-

Equipped with a 2kW heating system to maintain optimal adhesive viscosity.

-

Ensures glue flows evenly through the adhesive pen, improving bonding and preventing clogging.

Practical Applications and Industry Benefits

Ideal for Women’s Pointed-Toe Shoes

-

The precise adhesive application and visual locus guidance make the TH-888MAS especially suited for pointed-toe designs, which require careful glue placement to avoid deformation or material damage.

Soft and Thin Midsole Shoes

-

Shoes with soft or thinner midsoles typically challenge lasting machines due to deformation risks and glue absorption variability.

-

The servo control and precise glue application mitigate these issues, providing a balanced adhesive layer that supports the shoe structure without excess pressure.

High-Volume Production

-

With a productivity rate of 1440 pairs per 8 hours, this machine supports high-throughput manufacturing, ideal for factories aiming to increase output without compromising quality.

Customization and Flexibility

-

The large memory for shoe type settings allows manufacturers to switch between multiple shoe models quickly, supporting diverse product lines without lengthy changeovers.

Maintenance and Support

-

Diagnostic Functionality: The PLC system’s error diagnostics allow maintenance teams to quickly identify issues such as motor malfunctions, hydraulic pressure drops, or sensor errors.

-

Remote Support: With optional IoT features, technical teams can monitor machine performance remotely, reducing the need for onsite troubleshooting.

-

Spare Parts Availability: The TH-888MAS is designed with modular components for easy replacement and minimal disruption.

Summary of Benefits

| Benefit | Description |

|---|---|

| High Precision | Five-axis servo control ensures perfect glue application on complex shoe toe designs. |

| Increased Productivity | No glue tray design and rapid shoe type switching increase uptime and output. |

| Labor Cost Reduction | Reduced adhesive overflow and cleanup lowers manual labor needs. |

| Cost Savings | Efficient adhesive use cuts material waste and disposal costs. |

| Ease of Use | Touchscreen interface and memory control simplify operation and reduce errors. |

| Flexibility | Memory stores up to 500 shoe-lasting programs for diverse production requirements. |

| Stability and Durability | A fully oil-pressure system ensures consistent and stable machine operation over long periods. |

| Smart Factory Ready | Optional IoT connectivity supports Industry 4.0 integration and predictive maintenance. |

The TH-888MAS Computer Memory Visual Locus Fully Servo Control Cementing Toe Lasting Machine represents a breakthrough in lasting technology for shoe manufacturing. By combining advanced servo control, precise adhesive application, and intelligent memory systems, it addresses common challenges in producing high-quality footwear with efficiency and cost-effectiveness. Its innovative no-glue-tray design and optional IoT capabilities make it a future-proof investment, ensuring shoe factories can meet modern production demands with excellence.

No posts found