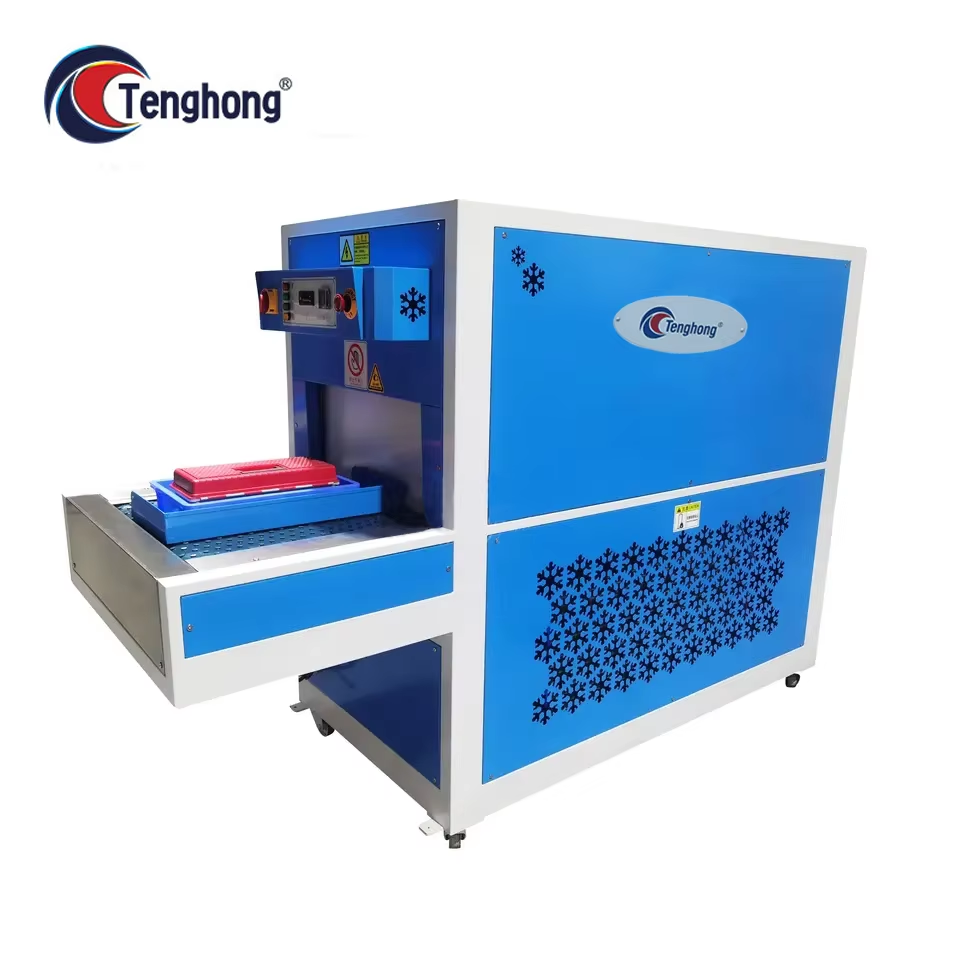

CHILLER MACHINE TH-828

MACHINE NAME: CHILLER MACHINE

MODEL NO: TH-828

BRAND: TENGHONG

FEATURES

- This machine is suitable for the shoes and the bottom pressure was frozen for shaping.

- The hot shoes quickly reduced to normal temperature, so the shoe last drawing is not easy to deformation.

- The use of double track automatic door durable; The use of special materials for the production of high quality conveyor belt use a longer life;

- Automatic defrosting device for shoes is not easy to mildew.

- The introduction of Germany advanced technology and the Import of the compressor and related components/Parts, refrigeration

- System cooling speed fast refrigeration effect is good, within a few minutes dropped to -15 °C. and the temperature is uniformity.

- Simple operation, easy maintenance. The machine of speed runs smoothly and the noise is very small.

- Because of the freezing time is short, good shaping effect, convenient transportation will expedite the turnover of last, reduce the production cost.

- Temperature range: Normal temperature to -15 °C. or specified. Installed with a sensor on output of the machine to prevent fall of shoes.

TECHNICAL PARAMETER

- Voltage : 380V/50Hz

- N. W. : 550Kg

- Power : 4/4.5/7KW

- Output : 1200/1800/2500pairs/8Hours

- Dimension : 2500/3200/4500x900x1700mm

The TH-828 Chiller is a high-performance industrial machine designed specifically for the rapid cooling and shaping of shoe lasts and uppers in the footwear manufacturing process. Its state-of-the-art refrigeration system, combined with innovative engineering and precision control, allows for quick freezing of shoes after shaping, preventing deformation and ensuring a consistent, high-quality finish. This machine is an essential asset in modern shoe production lines, supporting enhanced productivity, reduced costs, and superior product quality.

Product Overview

The TH-828 Chiller is expertly crafted to handle the critical process of shoe cooling immediately following heat shaping. When shoe uppers are molded on lasts during manufacturing, they must be cooled quickly to set the shape firmly before removal. Failure to cool efficiently can lead to deformation of the shoe last or vamp, adversely affecting the shoe’s final shape and structural integrity. This machine employs advanced refrigeration technology to freeze the shoe bottoms after pressure shaping, rapidly bringing the temperature down to preserve the perfect form. The efficient cooling cycle prevents the shoe last from warping or distorting during the cooling process, maintaining the precise contours and fit designed in earlier shaping stages.

Key Specifications

-

Available Lengths: 3.2 meters, 3.8 meters, 4.2 meters — catering to different production scale and shoe size requirements

-

Power Supply: Standard industrial 380V / 50Hz, compatible with most manufacturing facilities worldwide

-

Weight: Approximately 550 kg — robust construction ensures durability and stability during operation

-

Dimensions: 2500/3200/4500 mm (length) × 900 mm (width) × 1700 mm (height) — flexible sizing options provide compatibility with various factory layouts

-

Power Consumption: Models available with 4 kW, 4.5 kW, and 7 kW power ratings, balancing energy efficiency with cooling capacity

-

Production Capacity: Depending on the model, output ranges from 1200 to 2500 pairs per 8-hour shift, supporting both medium and high-volume manufacturing environments

Core Functionality

The TH-828’s primary function is to rapidly cool shoe uppers and lasts immediately after the heat shaping process, effectively locking in the shape and preventing deformation or shrinkage that can occur when hot shoe materials are cooled slowly.

Why Rapid Cooling Matters

During shoe manufacturing, especially in processes involving heat molding or steaming, the shoe upper and last are often hot and pliable when removed from the shaping equipment. If left to cool at ambient temperatures, the material may warp or lose its precise shape, resulting in defects, increased waste, and higher production costs. The TH-828 Chiller reduces the shoe temperature quickly and uniformly, generally reaching -15 °C within minutes, a critical temperature range that stabilizes the shoe’s form for safe removal from the last without damage. This fast chilling also means that the production line is not delayed waiting for shoes to cool naturally, allowing manufacturers to maintain a high throughput with consistent quality.

Innovative Features for Enhanced Performance

The TH-828 integrates several advanced features that differentiate it from conventional shoe cooling equipment:

Double-Track Automatic Door System

-

The machine incorporates double-track automatic doors, designed for durability and ease of use.

-

This mechanism ensures quick and secure loading and unloading of shoe lasts, minimizing manual handling and production downtime.

-

The smooth and reliable door operation enhances workflow efficiency and operator safety.

High-Quality Conveyor Belt

-

Constructed from special, durable materials, the conveyor belt is engineered for long-lasting performance, minimizing wear and maintenance costs.

-

The belt provides consistent movement and accurate positioning of shoe lasts through the cooling chamber, ensuring uniform chilling.

Automatic Defrosting Device

-

To prevent mildew and buildup within the cooling chamber, the TH-828 includes an automatic defrosting system.

-

This system periodically removes accumulated frost or moisture, maintaining optimal refrigeration performance and hygiene.

-

Continuous defrosting prolongs machine life and reduces downtime for manual cleaning.

German Advanced Refrigeration Technology

-

The machine features a refrigeration system based on advanced German technology, incorporating imported compressors and premium components.

-

This system delivers rapid cooling speeds and efficient refrigeration, ensuring the interior temperature drops to the target level swiftly and remains stable throughout operation.

-

The refrigeration components are carefully selected for reliability and longevity in demanding factory environments.

Uniform Cooling Distribution

-

The refrigeration system is engineered for uniform temperature distribution within the chamber, eliminating hot spots or uneven cooling that could distort shoes.

-

This consistency ensures every pair of shoes is cooled equally, maintaining product uniformity and reducing rejects.

Simple Operation and Maintenance

-

The TH-828 Chiller is designed for ease of use, featuring an intuitive control interface that minimizes operator training requirements.

-

Maintenance tasks are straightforward and accessible, allowing routine inspections and servicing without complex procedures or specialized tools.

-

The machine runs smoothly at a low noise level, improving working conditions within the manufacturing environment.

How the TH-828 Chiller Enhances Production Efficiency

The advantages of incorporating the TH-828 into a shoe production line extend beyond mere cooling speed:

Faster Turnaround and Increased Output

-

Rapid chilling shortens the overall production cycle by reducing the time shoes spend cooling after shaping.

-

This acceleration allows shoe manufacturers to increase throughput and meet higher order volumes without compromising quality.

Superior Shaping Stability

-

By stabilizing the shoe shape immediately, the machine reduces deformation risks associated with hot shoe handling.

-

The shoe last’s integrity is preserved, allowing precise vamp-to-last conformity and consistent shoe dimensions.

Reduced Production Costs

-

Improved process speed and fewer defective products translate directly into cost savings.

-

The automatic defrosting and durable conveyor belt reduce downtime and maintenance expenses.

Enhanced Product Quality

-

Uniform chilling maintains the leather or synthetic upper’s surface quality, preventing cracks, wrinkles, or gloss loss caused by uneven cooling or overheating.

-

Shoes maintain their designed fit and form, meeting stringent quality control standards.

Operational Details

The TH-828 is engineered for seamless integration into shoe production lines. Here is a typical operational flow:

-

Loading: Shoes or boots, after shaping, are placed onto the conveyor belt. The double-track automatic doors open smoothly to allow loading.

-

Rapid Cooling Cycle: Once inside the cooling chamber, the refrigeration system activates, and within minutes, the shoes are cooled down to approximately -15 °C.

-

Monitoring: Sensors installed on the output prevent accidental shoe falls and help control the flow of finished shoes exiting the machine.

-

Unloading: After the cooling cycle, shoes exit the chamber smoothly and can be transported or processed immediately.

This operation ensures a continuous, efficient workflow that supports high production volumes with minimal manual intervention.

Temperature Control and Customization

While the standard temperature range covers normal room temperature down to -15 °C, the TH-828 offers customized temperature settings tailored to specific shoe materials or production requirements.

Manufacturers can specify particular cooling temperatures to optimize results for:

-

Delicate leathers require gentler cooling

-

Synthetic materials that may have different thermal sensitivities

-

Boots or large footwear needing extended chilling time

This flexibility enhances the machine’s applicability across diverse product lines.

Durability and Build Quality

The TH-828 is constructed using industrial-grade materials designed to withstand the rigors of high-volume footwear manufacturing:

-

The outer casing is robust, protecting against factory impacts and environmental factors.

-

Internal refrigeration components are sourced from leading global suppliers, ensuring longevity and reliable operation.

-

The conveyor belt and door tracks utilize wear-resistant materials, designed for continuous operation without degradation.

These build quality elements contribute to a low total cost of ownership and reduced downtime.

Safety Features

Safety is a critical consideration in the design of the TH-828 Chiller:

-

The machine includes sensors at the output end to detect and prevent shoe falls, protecting products and operators.

-

Automatic door mechanisms are engineered with safety interlocks to prevent accidental opening during operation.

-

Electrical components and refrigeration systems comply with industrial safety standards, reducing the risk of faults or hazards.

These safety features create a secure working environment and help maintain steady production.

Environmental Considerations

The TH-828 Chiller incorporates energy-efficient technologies and environmentally friendly refrigerants to minimize its ecological impact:

-

Advanced compressors and refrigeration cycles reduce power consumption compared to older models.

-

Refrigerants used comply with international environmental regulations to reduce ozone depletion and greenhouse gas emissions.

-

Efficient insulation within the cooling chamber limits thermal loss, reducing the need for excessive energy input.

This environmentally responsible design makes the TH-828 a future-ready solution for sustainable footwear manufacturing.

Installation and Maintenance Support

The TH-828 is designed for easy installation and integration:

-

Compact footprint allows installation even in limited factory space.

-

Modular design supports integration with existing production lines and conveyor systems.

-

Comprehensive manuals and on-site support help manufacturers quickly commission the machine and train operators.

Routine maintenance is facilitated by easy access panels and clearly labeled components, ensuring quick troubleshooting and servicing.

Why Choose the TH-828 Chiller?

For footwear manufacturers aiming to optimize their heat shaping and cooling processes, the TH-828 Chiller offers an unparalleled combination of:

-

High-speed, uniform chilling to maintain shoe shape integrity

-

Energy-efficient refrigeration reduces operational costs

-

Robust build quality ensures long-term reliability

-

Flexible sizing and customization to suit varied production needs

-

User-friendly controls and low noise operation improve factory workflow

This machine empowers manufacturers to produce footwear at scale without sacrificing quality or efficiency.

The TH-828 Chiller stands out as a critical component in modern footwear manufacturing, delivering reliable, rapid shoe cooling and shaping to ensure premium product quality and production efficiency. Its sophisticated refrigeration system, durable construction, and intelligent safety features make it an ideal choice for footwear factories looking to enhance their manufacturing processes and meet growing market demands. By investing in the TH-828, manufacturers can achieve faster turnover, reduce material waste, and produce consistent, high-quality shoes with every batch, a true competitive advantage in today’s demanding footwear industry.

No posts found