COMPUTER PNEUMATIC AUTOMATIC HEEL SEAT LASTING MACHINE TH-729

MACHINE NAME: COMPUTER PNEUMATIC AUTOMATIC HEEL SEAT LASTING MACHINE

MODEL NO: TH-729

BRAND: TENGHONG

FEATURES

- The first pneumatic wiper function, the wiper is equipped with heating and adjustable stoke, the use of pneumatic wiper strength more flexible.

- The first band mechanism adopts the lever principle for pulling, the pneumatic pulling force is more flexible and the pulling effect is more even.

- Using a dual-cylinder design, the shoe last can be flipped, with continuous movements that are more ergonomic and efficient in output under the same stroke.

- Shoe last positioning device, with built-in photoelectric switch and adjustable sensor head to ensure consistent heel shaping position.

- Intelligent control with human-machine interface supports Modbus, TCP, and Ethernet protocols, which can be connected with factory MES and ERP systems to realize digital management easily.

TECHNICAL PARAMETER

- Power : 2.2Kw

- Oil pressure : 50Kg/Cm2

- Productivity : 1500pairs/8H

- Oil filling : 80 L

- N.W : 1260Kg

- Dimension : 1780(L)x1400(W)x2150(H)mm

- Packing Size : Be provided before shipment.

The TH-729 Computer Pneumatic Automatic Heel Seat Lasting Machine represents a breakthrough in the field of footwear manufacturing technology. Designed for maximum flexibility, precision, and efficiency, the TH-729 integrates advanced pneumatic components with intelligent computerized control to deliver superior heel seat lasting performance. This machine is especially engineered to meet the evolving demands of modern shoe factories, combining mechanical innovation, ergonomic operation, and seamless digital integration. The TH-729’s unique features, such as pneumatic wiper technology, a novel band pulling mechanism, and dual-cylinder design for shoe last flipping, significantly boost production capacity and product quality. The machine’s smart control interface supports modern factory protocols, enabling integration with MES (Manufacturing Execution Systems) and ERP (Enterprise Resource Planning) platforms for complete digital factory management.

Core Innovations and Features Overview

The TH-729 is packed with innovative design elements that distinguish it from conventional heel seat lasting machines. The five key technological breakthroughs that form the foundation of this machine’s outstanding capabilities are:

-

First Pneumatic Wiper Function: A heated, adjustable stroke pneumatic wiper enhances flexibility and improves material handling during the lasting process.

-

Band Mechanism Lever Principle: Utilizing a lever-based band pulling mechanism with pneumatic force ensures even pulling and precise positioning of heel seats.

-

Dual-Cylinder Shoe Last Flipping: A unique dual-cylinder setup enables ergonomic, continuous shoe last flipping movements, increasing throughput without sacrificing stroke length.

-

Advanced Shoe Last Positioning Device: Incorporating built-in photoelectric switches and adjustable sensor heads guarantees accurate, consistent heel shaping positions.

-

Intelligent Human-Machine Interface (HMI): Supports Modbus, TCP/IP, and Ethernet protocols to connect seamlessly with MES and ERP systems, enabling smart digital factory management.

Detailed Technical Description

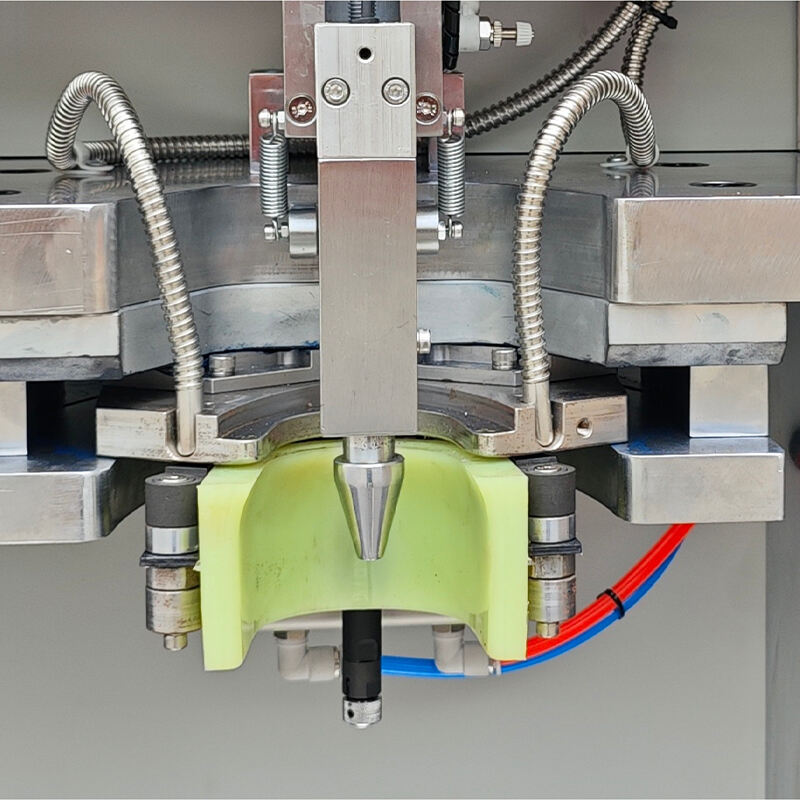

Pneumatic Wiper with Heating and Adjustable Stroke

The pneumatic wiper is a revolutionary component designed for flexible and efficient material manipulation during heel seat lasting. Traditional lasting machines often use mechanical wipers with fixed strokes, limiting their adaptability.

-

Heating Function: The wiper incorporates an integrated heating element, allowing it to soften adhesive layers or synthetic materials during the lasting process. This feature ensures better adhesion and reduces the risk of material deformation.

-

Adjustable Stroke: Operators can adjust the stroke length of the wiper pneumatically, allowing customization for different shoe sizes and material thicknesses. This adaptability improves the precision of the finishing process, reduces wear on materials, and enhances overall finishing quality.

-

Pneumatic Operation: Using pneumatic technology makes the wiper faster, smoother, and more responsive compared to purely mechanical alternatives. This reduces cycle times and increases machine uptime.

-

Flexibility: The wiper can be controlled remotely via the machine’s HMI interface, offering the operator the ability to adjust settings dynamically to accommodate different production needs without manual intervention.

Innovative Band Mechanism with Lever Principle and Pneumatic Pulling Force

The first band mechanism in the TH-729 utilizes the lever principle, combined with pneumatic pulling force, to achieve an even, controllable, and highly flexible heel seat attachment.

-

Lever Principle: This mechanical design multiplies the applied force, allowing a more even distribution of pressure across the heel seat band during pulling. This ensures uniform tension, which is critical for maintaining heel shape and avoiding wrinkles or loose adhesion.

-

Pneumatic Force Flexibility: Pneumatic actuators deliver variable pulling force that can be fine-tuned according to shoe design or material specifications. This results in precise control over the lasting force applied, optimizing product durability and comfort.

-

Uniform Pulling Effect: Thanks to the lever mechanism, the pulling action is smooth and consistent, reducing material stress and minimizing defects.

-

Reduced Maintenance: Pneumatic components are easier to maintain than complex mechanical pulling systems, lowering downtime and operating costs.

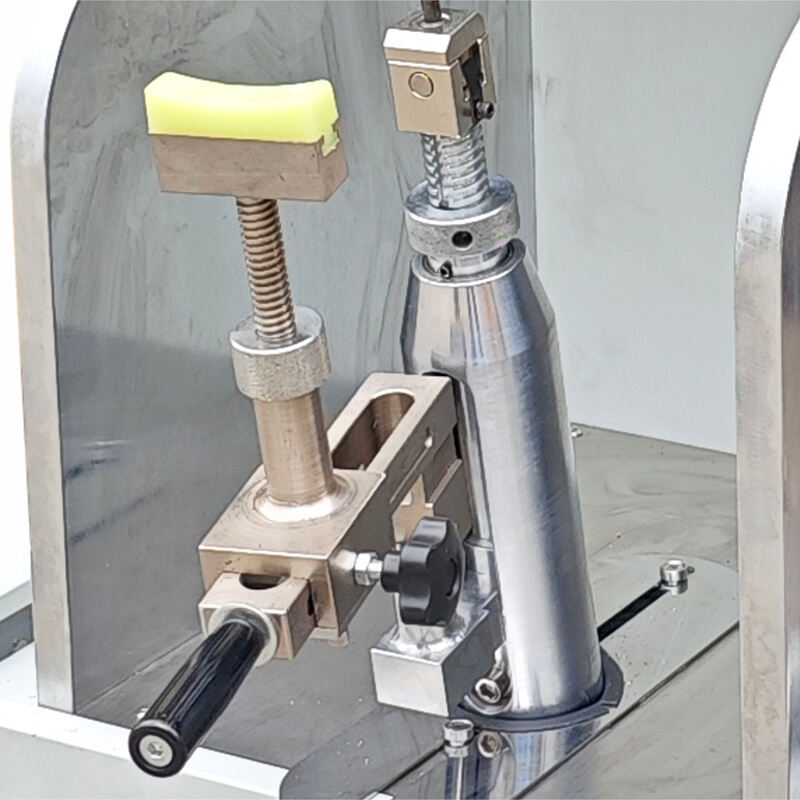

Dual-Cylinder Design for Efficient Shoe Last Flipping

A standout feature of the TH-729 is its dual-cylinder pneumatic design, enabling shoe last flipping with continuous and ergonomic movements.

-

Continuous Movement: The dual-cylinder arrangement allows the shoe last to flip smoothly and rapidly between positions without stopping, which significantly increases output efficiency.

-

Ergonomic Design: This design reduces the operator’s physical effort and minimizes repetitive strain injuries, contributing to a safer workplace.

-

Same Stroke Efficiency: Even with the same stroke length as conventional machines, the dual-cylinder design achieves higher throughput, optimizing production line speed.

-

Precision Control: The flip motion is precisely controlled to avoid damaging delicate shoe parts and maintain consistent shaping.

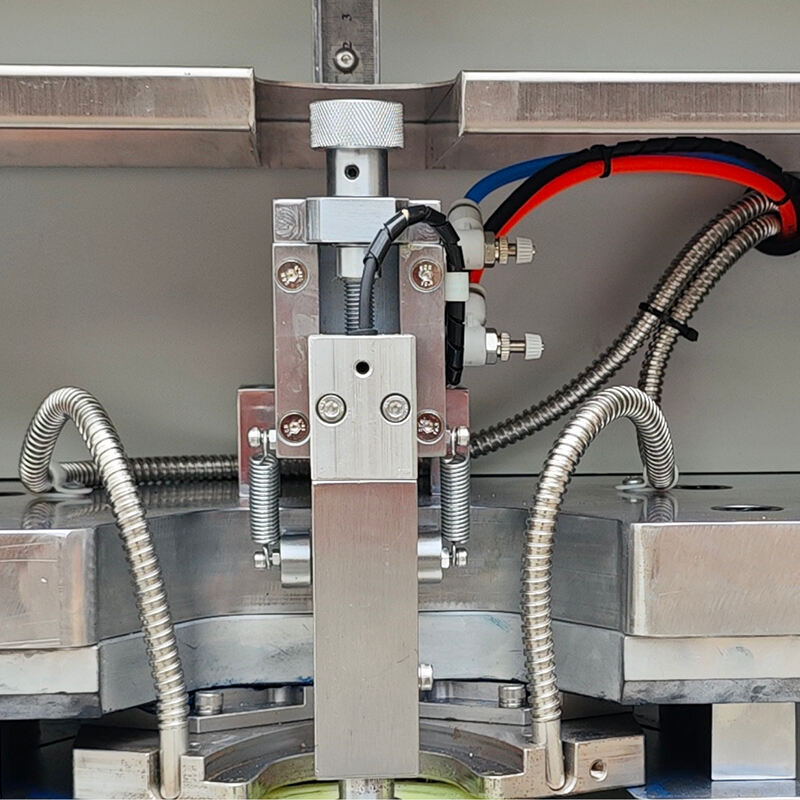

Shoe Last Positioning Device with Photoelectric and Adjustable Sensors

Accurate positioning of the shoe last is vital to ensure consistent heel shaping and quality control. The TH-729 incorporates an advanced positioning device featuring:

-

Built-in Photoelectric Switch: This sensor detects the exact position of the shoe last, enabling the machine to automatically adjust and confirm placement before the lasting process begins.

-

Adjustable Sensor Head: Operators can fine-tune the sensor head location to accommodate different shoe sizes and heel styles, ensuring versatility.

-

Consistent Heel Shaping Position: With real-time feedback from the sensors, the machine automatically corrects misalignments, preventing defects caused by poor positioning.

-

Increased Yield: The precision positioning reduces rework and waste, lowering manufacturing costs.

Intelligent Control with Advanced Human-Machine Interface (HMI)

The TH-729 is designed for today’s smart factories, featuring a sophisticated control system that facilitates digital manufacturing management.

-

Human-Machine Interface (HMI): A user-friendly, color touchscreen interface provides full control over machine parameters, including wiper stroke, pneumatic pressures, flipping cycles, and more.

-

Communication Protocols: The machine supports Modbus, TCP/IP, and Ethernet protocols, allowing it to integrate easily with a wide range of MES and ERP systems. This connectivity enables real-time production monitoring, data collection, and remote diagnostics.

-

Digital Factory Management: By connecting to MES/ERP, manufacturers can automate production scheduling, quality control, inventory management, and reporting, greatly improving operational efficiency.

-

Customizable Program Storage: Operators can save multiple lasting programs tailored to different shoe designs, enabling quick changeovers and reducing setup times.

-

Alarm and Diagnostics: The HMI interface provides comprehensive alarm notifications and diagnostics to minimize downtime.

Operational Workflow

To understand the TH-729’s full capabilities, let’s walk through its typical operational workflow:

-

Preparation: The operator places the shoe with the heel seat pre-positioned onto the shoe last mounting area.

-

Program Selection: Using the touchscreen, the operator selects or customizes the lasting program that matches the shoe’s heel size and material.

-

Automatic Clamping: Pneumatic clamps engage to securely hold the shoe and heel seat in place.

-

Pneumatic Wiper Activation: The heated wiper with adjustable stroke applies soft, precise pressure to smooth and fix the heel seat adhesive layer.

-

Band Pulling: The lever-based band mechanism pneumatically pulls the heel seat evenly, ensuring a tight and uniform fit.

-

Shoe Last Flipping: The dual-cylinder system flips the shoe last smoothly to the next position, preparing for the subsequent steps or unloading.

-

Positioning Feedback: Photoelectric sensors confirm heel alignment and make any necessary adjustments automatically.

-

Cycle Completion: Upon finishing the cycle, the clamps release, and the finished shoe is removed for further processing or packaging.

This process repeats rapidly and consistently, producing high-quality lasted shoes at increased volumes.

Advantages and Benefits

Enhanced Production Efficiency

The integration of pneumatic technology and dual-cylinder flipping significantly reduces the cycle time per shoe, increasing daily output.

Superior Product Quality

The even pulling force, heated pneumatic wiper, and precise positioning sensors combine to ensure flawless heel seat attachment, improving shoe durability and customer satisfaction.

Flexible Adaptability

Adjustable wiper stroke, sensor heads, and programmable controls allow the machine to handle a wide variety of shoe types, sizes, and materials with minimal downtime.

Seamless Digital Integration

With full support for industry-standard communication protocols, the TH-729 fits perfectly into smart manufacturing ecosystems, enabling real-time monitoring and control.

Operator Safety and Comfort

Ergonomic design and automated movements reduce physical strain, while safety features like emergency stops and sensor-guarded operations protect workers.

Cost Savings

Reduced manual labor, lower defect rates, and decreased maintenance needs translate into tangible cost savings and higher profit margins.

Technical Specifications

>td >Control System

| Parameter | Specification |

|---|---|

| Model | |

| PLC with Touchscreen HMI | |

| Power Supply | 380V / 3-phase / 50-60 Hz |

| Pneumatic Pressure | Adjustable up to 0.7 MPa |

| Heated Wiper Temperature | Adjustable up to 80°C |

| Wiper Stroke Length | Pneumatically adjustable (20-50 mm) |

| Band Pulling Force | Pneumatic, adjustable up to 1500 N |

| Cycle Time | 18-28 seconds per shoe |

| Heel Height Range | 3-12 cm |

| Shoe Size Range | Adjustable for US sizes 4-14 |

| Weight | Approx. 360 kg |

| Dimensions (L x W x H) | 1600 mm x 1100 mm x 1450 mm |

| Communication Protocols | Modbus, TCP/IP, Ethernet |

| Safety Features | Emergency stop, photoelectric guards |

| Operating Temperature Range | 0-40°C |

Installation Requirements and Maintenance

Installation

-

Power: 380V three-phase AC power source, stable and grounded.

-

Compressed Air: Stable supply at 0.6-0.7 MPa.

-

Foundation: Level concrete floor capable of supporting machine weight.

-

Environment: Clean, dry factory floor with adequate ventilation.

Routine Maintenance

-

Daily: Clean wiper and sensor surfaces, check air pressure.

-

Weekly: Inspect pneumatic hoses, clamps, and cylinders for leaks or wear.

-

Monthly: Lubricate mechanical parts and verify sensor calibrations.

-

Annual: Comprehensive service including software updates and hydraulic system checks.

Integration with MES and ERP Systems

Modern footwear manufacturers are moving towards fully integrated digital factories. The TH-729 supports this trend by enabling:

-

Real-Time Production Data: Monitoring machine status, cycle counts, and faults.

-

Production Scheduling: Dynamic control of machine programs aligned with factory workflow.

-

Quality Control Tracking: Automated logging of heel lasting parameters for traceability.

-

Remote Diagnostics: Technical teams can access machine data remotely for faster troubleshooting.

This level of integration helps manufacturers reduce downtime, optimize resources, and improve product consistency.

User Training and Support

The TH-729 package includes comprehensive user manuals, training sessions, and technical support to ensure operators and maintenance personnel can maximize machine performance.

-

Operator Training: Hands-on instruction on machine operation, program selection, and safety.

-

Maintenance Training: Guidance on preventive maintenance routines.

-

Technical Support: Remote and on-site support options available.

-

Software Updates: Regular updates for HMI and PLC software to enhance functionality.

The TH-729 Computer Pneumatic Automatic Heel Seat Lasting Machine is a cutting-edge solution for modern shoe manufacturers seeking to elevate quality, flexibility, and productivity. Its unique combination of pneumatic technology, intelligent control, and ergonomic design delivers consistent, high-quality heel lasting with lower operating costs and seamless digital factory integration. By investing in the TH-729, manufacturers can expect increased throughput, reduced defect rates, enhanced operator safety, and a smoother path toward Industry 4.0 smart factory standards.

No posts found