Computerized Automatic Heel Seat lasting Machine TH-728A

The TH-728A Computerized Automatic Heel Seat Lasting Machine represents the latest advancement in footwear manufacturing technology, designed to enhance efficiency, precision, and quality in the heel seat lasting process. As shoe manufacturing evolves, automation and computerization have become essential to meet growing production demands and maintain superior craftsmanship. The TH-728A integrates cutting-edge computerized control systems with mechanical precision to automate the complex process of lasting heel seats, drastically reducing manual labor and error rates. Whether for high-end fashion footwear, sports shoes, or industrial boots, the TH-728A offers unparalleled reliability and performance, enabling manufacturers to scale production while maintaining consistent quality.

What is Heel Seat Lasting and Why Does It Matter?

Heel seat lasting is a critical phase in shoe production. It involves fixing the heel seat, the part of the shoe that supports the heel firmly onto the shoe’s last (the foot-shaped mold). The precision of this process directly affects shoe comfort, stability, and durability. Traditional heel lasting methods rely heavily on manual labor, which can lead to inconsistent results, higher defect rates, and longer production cycles. Automated heel seat lasting machines like the TH-728A minimize these issues by ensuring uniform pressure and alignment through computer-controlled operations.

Product Overview

Model: TH-728A

Category: Computerized Automatic Heel Seat Lasting Machine

Application: Footwear manufacturing, heel seat lasting phase

Industry: Shoe factories, OEM/ODM footwear manufacturers, shoe repair workshops

The TH-728A is engineered to automatically clamp, press, and secure the heel seat to the shoe upper with high accuracy and repeatability. It incorporates a user-friendly computerized interface, programmable lasting programs, and robust mechanical components designed for high-volume production environments.

Key Features and Technical Specifications

Computerized Control System

-

PLC-Based Control: The TH-728A utilizes a Programmable Logic Controller (PLC) for precise control of all mechanical motions.

-

Touchscreen Interface: A high-definition color touchscreen panel allows operators to easily select and customize lasting parameters.

-

Memory Storage: Capable of storing multiple lasting programs for different shoe models, speeding up changeovers.

-

Real-Time Monitoring: Displays operational status, pressure levels, and error messages for immediate troubleshooting.

Mechanical Design

-

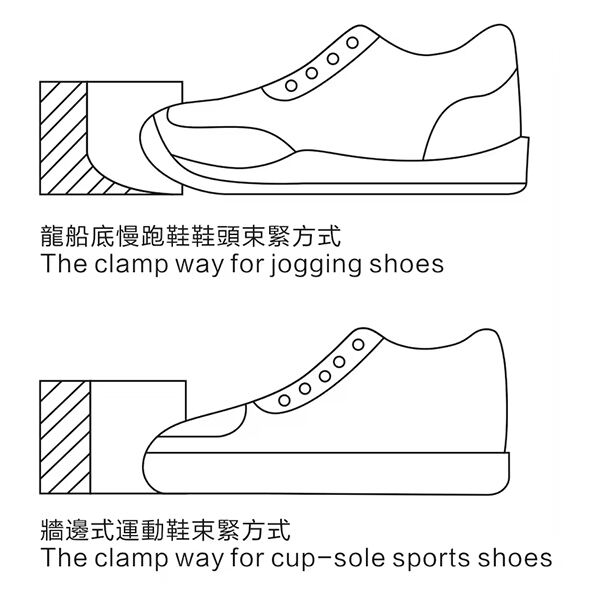

Automatic Clamping: Hydraulic clamps firmly secure the shoe and heel seat during lasting to prevent slippage.

-

Adjustable Pressure Control: Pressure sensors and hydraulic regulation ensure consistent pressing force tailored for different materials.

-

Precision Alignment: Mechanically guided heel positioning arms guarantee exact placement on the shoe last.

-

Durable Build: Heavy-duty steel frame and components designed to withstand continuous industrial use.

Performance

-

Cycle Time: Average lasting cycle of 20-30 seconds per shoe, optimizing throughput.

-

Heel Sizes: Adjustable for a wide range of heel sizes and shoe styles, from low heels to high heels.

-

Material Compatibility: Suitable for leather, synthetic uppers, rubber soles, and other common footwear materials.

-

Energy Efficiency: Designed with energy-saving hydraulic systems and low-power consumption electronics.

Safety Features

-

Emergency Stop Button: Immediate shutdown capability for safety.

-

Protective Guards: Covers and shields to protect operators from moving parts.

-

Overload Protection: Automatically stops operation if the mechanical overload is detected.

Detailed Operational Description

Setup and Programming

Operators begin by selecting or programming the lasting cycle on the touchscreen interface. Parameters such as heel size, pressing force, pressing time, and clamp position can be input manually or recalled from pre-saved programs.

Loading the Shoe

The operator places the shoe, already assembled with the heel seat loosely attached, onto the shoe last fixture integrated within the machine. The shoe last ensures the shoe maintains its correct shape during the lasting process.

Automatic Clamping and Positioning

Once the start button is pressed, hydraulic clamps automatically engage to secure the shoe and heel seat firmly in place. The positioning arms move to align the heel seat perfectly with the shoe last, using sensors to confirm accuracy.

Lasting Process

The hydraulic press then applies consistent pressure on the heel seat, pressing it onto the shoe upper and sole. The computer controls the pressure precisely, ensuring the heel is securely attached without damaging delicate materials.

Unloading

After the programmed cycle completes, the clamps release, and the operator removes the finished shoe. The process is then ready to repeat for the next pair.

Advantages of the TH-728A Heel Seat Lasting Machine

Increased Production Efficiency

By automating a traditionally labor-intensive process, the TH-728A drastically cuts down the time required per shoe, allowing factories to produce more units daily without compromising quality.

Consistent Quality and Precision

The computerized control eliminates variability caused by human operators, ensuring every heel seat is lathed to exact specifications critical for product consistency.

Reduced Labor Costs and Training

Automation reduces dependence on highly skilled manual workers, lowering labor costs and simplifying workforce training requirements.

Flexible Operation for Various Shoe Styles

With programmable settings and adjustable mechanical parts, the TH-728A accommodates different heel heights and shoe models, increasing its utility across product lines.

Enhanced Operator Safety

The machine’s safety features protect workers from mechanical hazards, creating a safer workplace environment.

Typical Applications

The TH-728A is widely used in:

-

Footwear OEM and ODM manufacturers: For high-volume shoe production runs.

-

Specialty shoe factories: Producing custom heels or high-fashion footwear.

-

Sports shoe manufacturers: Where precise heel attachment is essential for performance.

-

Shoe repair workshops: For durable heel seat replacement.

-

Educational institutions: Teaching modern footwear manufacturing technology.

Installation and Maintenance

Installation Requirements

-

Power Supply: 380V three-phase AC, 50/60 Hz

-

Compressed Air: Minimum 0.6 MPa (for pneumatic components)

-

Floor Space: Approximately 1.5 m x 1 m footprint

-

Foundation: Level concrete base recommended for stability

Routine Maintenance

-

Daily: Clean machine surfaces, check hydraulic fluid levels.

-

Weekly: Inspect clamps and pressure sensors for wear.

-

Monthly: Lubricate moving parts, tighten all mechanical fasteners.

-

Yearly: Comprehensive service by authorized technicians, including PLC software updates.

Proper maintenance ensures optimal machine performance and extends its operational lifespan.

Technical Support and Training

Manufacturers typically provide comprehensive technical support packages with the TH-728A, including:

-

On-site installation and commissioning.

-

Operator training sessions for programming and maintenance.

-

Access to online manuals and troubleshooting guides.

-

Spare parts supply and after-sales service contracts.

Market Positioning and Competitiveness

The TH-728A stands out among heel-lasting machines for its blend of automation, flexibility, and ease of use. Competing products may offer manual or semi-automatic operation, but the fully computerized TH-728A delivers superior precision and throughput.

Its modular design and programmable interface also future-proof it against evolving manufacturing needs, making it a valuable long-term investment for footwear manufacturers targeting both quality and scale.

Environmental Considerations

-

The machine’s energy-efficient design reduces power consumption.

-

The hydraulic fluids used are compliant with environmental safety standards.

-

Minimal material waste is generated due to precise pressing control.

-

Helps factories reduce their carbon footprint by optimizing production efficiency.

Summary of Benefits

| Benefit | Description |

|---|---|

| Automation | Reduces manual labor and error |

| Computerized Control | High precision and repeatability |

| Fast Cycle Time | 20-30 seconds per shoe |

| Wide Shoe Compatibility | Adjustable for various heel sizes and materials |

| Durable Construction | Long-lasting industrial-grade components |

| User-Friendly Interface | Easy programming and operation |

| Safety Features | Protect operators and prevent accidents |

| Cost Efficiency | Lowers labor costs and reduces defects |

| Technical Support | Full training, maintenance, and spare parts availability |

Detailed Technical Specifications Table

>td >Control System

| Specification | Details |

|---|---|

| Model | |

| PLC with touchscreen interface | |

| Power Supply | 380V / 3-phase / 50-60 Hz |

| Compressed Air | ≥ 0.6 MPa |

| Pressing Force | Adjustable, max up to 2000 N |

| Cycle Time | 20-30 seconds per shoe |

| Heel Size Range | Adjustable for 3-12 cm heel heights |

| Material Compatibility | Leather, synthetic, rubber soles |

| Machine Weight | Approx. 350 kg |

| Dimensions (L x W x H) | 1500 mm x 1000 mm x 1400 mm |

| Safety Features | Emergency stop, overload protection, guards |

| Memory Capacity | Stores up to 20 different lasting programs |

| Operating Temperature Range | 0-40°C |

Frequently Asked Questions (FAQs)

Can the TH-728A handle high-heeled shoes?

Yes, it supports a wide heel height range up to 12 cm, suitable for low to high heels.

Is the machine easy to program?

The touchscreen interface is intuitive, and operators can save multiple lasting profiles for different shoe styles.

What is the expected maintenance frequency?

Daily cleaning, weekly checks, and annual comprehensive servicing ensure optimal performance.

Does it require skilled operators?

Basic training is sufficient, thanks to automation and user-friendly controls.

What is the warranty period?

Typically, a 12-month warranty covers parts and labor, with optional extended service contracts.

How TH-728A Improved Productivity for a Leading Footwear Manufacturer

A major footwear manufacturer integrated the TH-728A into their production line, replacing manual heel seat lasting. The result was a 35% increase in daily output, a 50% reduction in material defects, and improved worker safety. The machine’s programmable controls allowed quick transitions between different shoe models, enabling greater product variety without downtime.

The Future of Heel Seat Lasting

The TH-728A Computerized Automatic Heel Seat Lasting Machine is an essential tool for modern shoe manufacturing enterprises looking to optimize production efficiency, quality, and safety. Its combination of advanced computerized controls, robust mechanical design, and user-friendly operation makes it an investment that pays off through enhanced throughput and superior footwear quality. Manufacturers adopting the TH-728A are well-positioned to meet evolving market demands, maintain a competitive advantage, and deliver exceptional products to consumers worldwide.

No posts found