Hydraulic Automatic Heel Seat lasting Machine TH-727DP

The TH-727DP Hydraulic Automatic Heel Seat Lasting Machine is a cutting-edge, fully automatic solution designed for high-precision and high-efficiency lasting operations specifically targeting the heel seat area in shoe manufacturing. It combines the advantages of hydraulic power, intelligent automation, and mechanical precision to offer exceptional results for all types of footwear production, including men’s, women’s, and children’s shoes. Whether used in small-scale bespoke workshops or high-volume industrial production lines, the TH-727DP delivers consistent quality, reduces operator workload, and enhances overall productivity. Engineered with advanced ergonomics and built-in safety mechanisms, it is ideal for modern footwear factories seeking durability, flexibility, and digital control in heel seat lasting.

Hydraulic Drive System

The TH-727DP utilizes a high-performance hydraulic system to ensure smooth, stable, and powerful pressing of the heel seat. Unlike traditional mechanical systems, hydraulic pressure is evenly distributed, eliminating inconsistencies and achieving uniform adhesion between the upper and insole.

-

Stable and consistent lasting pressure.

-

Adjustable hydraulic pressure to suit different shoe types.

-

Long-lasting and low maintenance with sealed fluid reservoirs.

Automatic Lasting Operation

Fully automated operation minimizes manual involvement and maximizes production efficiency. The TH-727DP's intelligent logic controllers synchronize the movement of pressing pads and the conveyor for precise automatic lasting.

-

Programmable logic control (PLC) for precision.

-

Seamless integration into automated production lines.

-

Significant reduction in operator fatigue.

Intelligent Heel Positioning

A major highlight of the TH-727DP is its intelligent heel seat alignment system, ensuring exact positioning of the heel section before the lasting operation begins.

-

Laser or optical sensors assist in upper alignment.

-

Auto-detection of heel position for optimal pressure placement.

-

Reduced errors and rejects due to misaligned lasting.

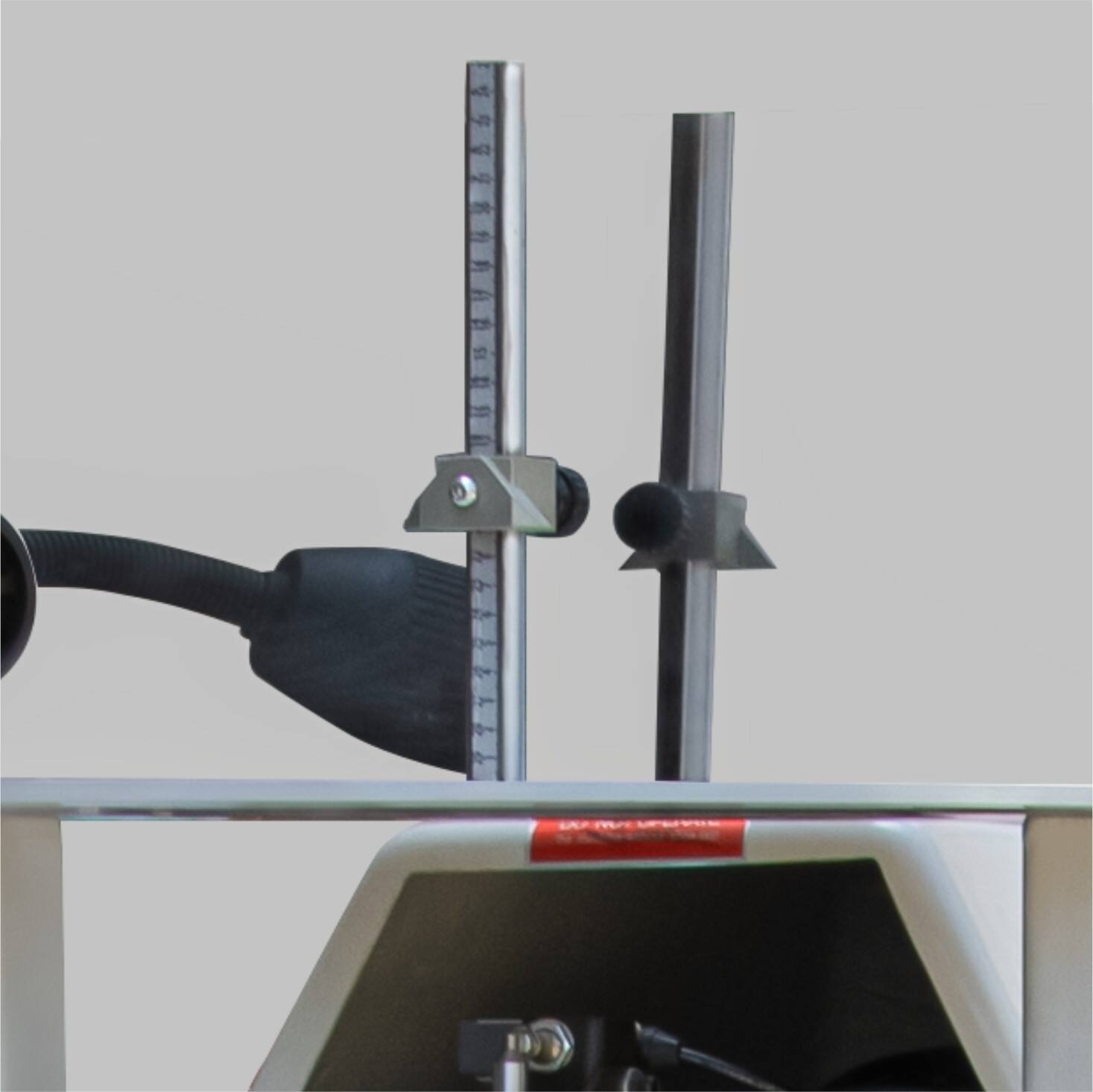

Customizable Shoe Last Support

To accommodate a wide range of shoe designs and sizes, the TH-727DP offers adjustable shoe last supports, both horizontally and vertically. The system supports shoe sizes ranging from children's footwear to adult boots.

-

Quick-change last clamps.

-

Adjustable heel height and angle.

-

Memory recall for frequently used size settings.

Energy Efficient Operation

Hydraulic systems are optimized for low power consumption. Combined with energy-saving standby modes and intelligent controls, the machine ensures minimal power wastage during idle times.

-

Low-power hydraulic pump.

-

Auto shutoff and sleep mode.

-

Green manufacturing compliance.

User-Friendly Control Interface

The integrated touchscreen panel allows for intuitive control and real-time monitoring of the lasting operation. Operators can select modes, adjust pressure, and store parameters easily.

-

7-inch industrial-grade touchscreen.

-

Multi-language interface support.

-

Error diagnostics and maintenance alerts.

Compact and Durable Design

Built for durability in demanding factory environments, the TH-727DP features a rugged steel frame, corrosion-resistant components, and vibration-dampening mounts.

-

Space-saving vertical design.

-

Anti-corrosion coating for humid environments.

-

Built-in safety interlocks and emergency stop.

Technical Specifications

| Detail |

|---|

| TH-727DP |

| Hydraulic Automatic Heel Seat Lasting |

| PLC with touchscreen interface |

| Closed-loop, high-pressure system |

| 380V / 50Hz (customizable) |

| 3.0 – 3.5 kW |

| 1500 kg |

| 9-point adjustable pressing fingers |

| EU 26 – 48 |

| Up to 2000 pairs per 8-hour shift |

| Leather, Synthetic, Rubber, EVA, etc. |

| Automatic centralized lubrication |

| 1550 × 1050 × 1800 mm |

| 820 kg |

| Emergency stop, guard sensors, alarms |

| CE, ISO9001 |

Working Principle

The TH-727DP works by accurately pressing the heel seat area of a shoe upper onto the insole-covered last. The process begins by positioning the shoe on the last, either manually or via an automated conveyor. The machine then engages its heel-holding mechanism and activates the hydraulic pressing fingers that uniformly press and shape the heel seat over the last.

-

The Upper is pulled over the last and positioned.

-

Sensors check the positioning of the upper.

-

Pressing pads descend and exert uniform pressure.

-

Pressure is held for a precise time to ensure bonding.

-

Pads retract, and the shoe is removed or advanced automatically.

The uniformity and control offered by the hydraulic system prevent deformation, reduce adhesive gaps, and improve the final quality of the shoe.

Benefits

High Productivity

With a cycle time of less than 15 seconds per shoe, the TH-727DP offers unmatched productivity for heel lasting operations. It enables mass production with consistent output, making it ideal for factories targeting high daily output.

Consistent Quality

Eliminating manual pressure variation, the hydraulic system ensures identical heel shaping for every pair. This consistency greatly improves customer satisfaction and brand reputation.

Reduced Labor Dependency

Automated heel seat lasting reduces the number of skilled laborers required on the production floor. Operators only need minimal training to manage the machine, significantly cutting down labor costs.

Lower Defect Rates

Thanks to its intelligent alignment and pressure control, the TH-727DP dramatically reduces the chances of poorly attached heel sections or wrinkled uppers, contributing to a lower rejection rate.

Wide Material Compatibility

Whether the upper is made from genuine leather, PU, synthetic fibers, or canvas, the machine can be calibrated to provide the correct pressure and heat (if needed), ensuring superior bonding regardless of material.

Applications

The TH-727DP is versatile and applicable across a range of shoe types and manufacturing environments:

-

Men’s Dress Shoes – Precision lasting for leather uppers.

-

Women’s Heels and Boots – Accurate shaping of extended heel sections.

-

Sports Shoes – Quick, consistent lasting of synthetic uppers.

-

Children’s Footwear – Adjustable for smaller lasts and materials.

-

Military and Industrial Shoes – Robust pressure for heavy-duty materials.

This machine is perfect for:

-

Footwear manufacturers

-

OEM shoe factories

-

Shoe prototyping workshops

-

Custom or bespoke shoe brands

-

High-speed shoe assembly lines

Customizable Options

To cater to different production needs, the TH-727DP can be upgraded or modified with:

-

Optional heating elements for thermoplastic materials.

-

Extended pressing arms for high-top shoes or boots.

-

Integration kits for conveyor-based assembly lines.

-

IoT-enabled modules for remote diagnostics and analytics.

-

Customized color finishes for branding purposes.

Maintenance and Support

Routine Maintenance

The TH-727DP is designed for easy access and minimal downtime. The automatic lubrication system ensures all moving parts are well-oiled, extending component life.

Recommended Maintenance Schedule:

-

Daily: Check hydraulic fluid level and clean pressing pads.

-

Weekly: Inspect seals, hoses, and alignment sensors.

-

Monthly: Perform full system diagnostics via the touchscreen.

-

Yearly: Replace hydraulic fluid and filter.

Technical Support

Each machine is backed by global after-sales support, including:

-

On-site installation and training.

-

12-month warranty on parts and labor.

-

Remote troubleshooting and software updates.

-

Access to genuine replacement parts and consumables.

Safety and Compliance

Worker safety is a top priority. The TH-727DP comes with:

-

Safety guards around all moving parts.

-

Emergency stop switches are on all accessible sides.

-

Over-pressure protection in the hydraulic circuit.

-

Auto-lock system during maintenance mode.

-

Certified under CE standards and ISO 9001 guidelines.

Why Choose TH-727DP?

In today’s fast-paced footwear industry, manufacturers cannot afford subpar heel lasting or manual inconsistencies. The TH-727DP Hydraulic Automatic Heel Seat Lasting Machine offers a robust, intelligent, and high-throughput solution. Here's why it's an excellent investment:

| Benefit |

|---|

| Reduces labor costs, increases efficiency |

| Uniform pressure, superior lasting |

| High precision and easy customization |

| Simple learning curve for operators |

| Ideal for space-constrained factories |

| Lower operating costs over time |

| Suitable for nearly all footwear styles |

| Minimal downtime, fast maintenance |

The TH-727DP Hydraulic Automatic Heel Seat Lasting Machine stands as a testament to the fusion of automation and craftsmanship in modern footwear production. Designed for consistent output, reduced labor intervention, and excellent heel shaping precision, it is the ideal solution for manufacturers looking to optimize their lasting processes. From global footwear giants to boutique shoe artisans, the TH-727DP is trusted for its reliability, precision, and performance. Whether you are upgrading from older semi-manual systems or expanding an existing production line, this machine is the ultimate heel seat lasting companion for today's competitive shoe industry.

No posts found