Hydraulic Automatic Heel Seat Lasting Machine TH-727A

The TH-727A Heel Seat Lasting Machine is a state-of-the-art solution designed to enhance the efficiency and precision of heel seat lasting in shoe manufacturing. Engineered with advanced features, this machine ensures consistent quality, adaptability, and ease of operation, making it an indispensable asset for modern footwear production lines.

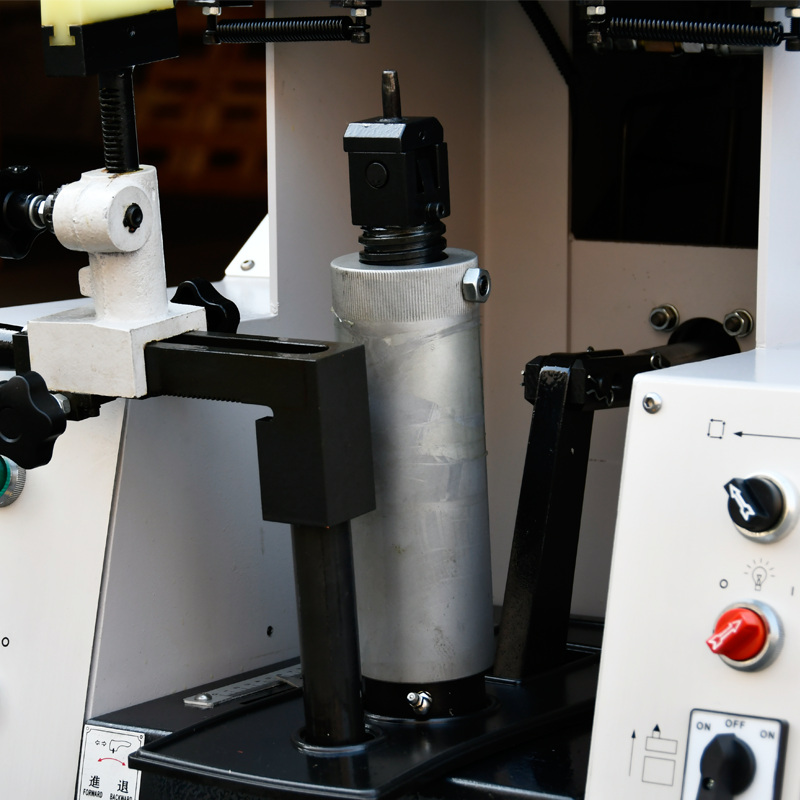

Adjustable Shoe Last Height with Accurate Positioning

The TH-727A is equipped with a mechanism that allows for the easy adjustment of the shoe last height. This feature ensures accurate positioning, accommodating various shoe sizes and designs. The precise adjustment capability enhances the machine's versatility and contributes to consistent production quality.

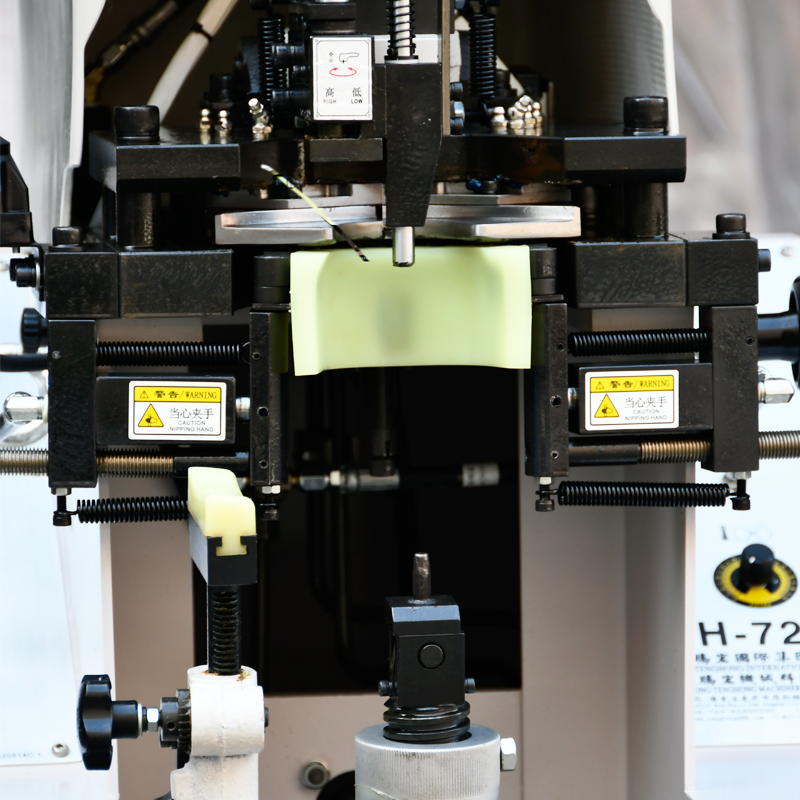

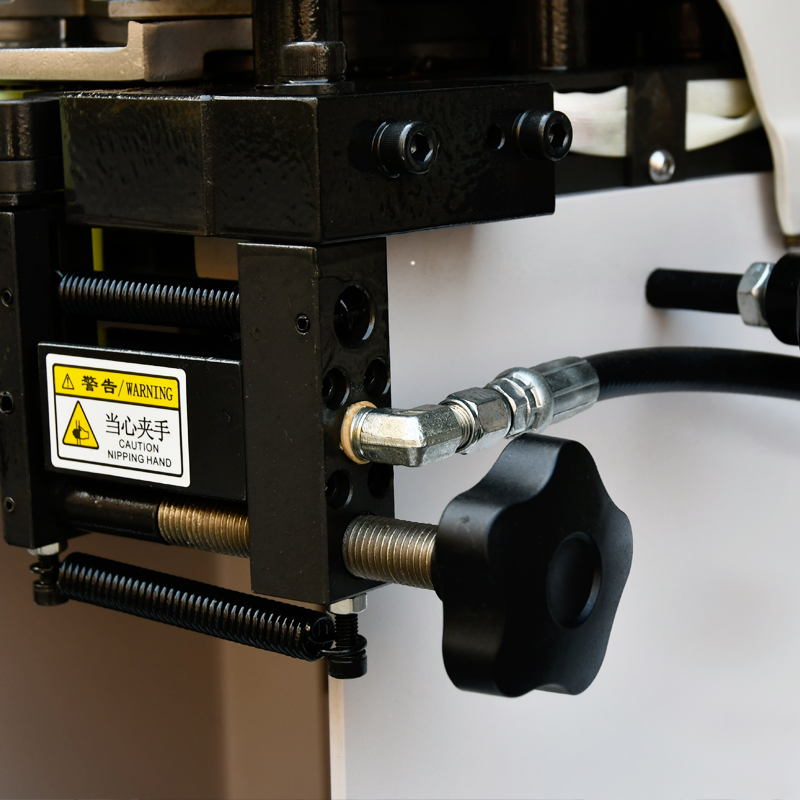

Chain-Like Wrapping Method for Effective Band Tightening

Utilizing a chain-like wrapping method, the TH-727A achieves superior band tightening around the heel seat. This technique ensures a snug fit, reducing the likelihood of wrinkles or misalignment in the upper material. The result is a more refined and durable finish in the heel area of the shoe.

Integrated Heating Device for the Wiper

The machine incorporates a heating device for the wiper component, which plays a crucial role in the lasting process. The application of heat aids in molding the upper material more effectively, enhancing the adhesion and overall quality of the heel seat. This feature is particularly beneficial when working with materials that require heat activation for optimal shaping.

Adjustable Temperature Settings

Recognizing the diverse requirements of different materials and adhesives, the TH-727A offers adjustable temperature settings. Operators can set the temperature according to the specific needs of the production process, ensuring optimal performance and preventing material damage due to overheating.

Suitability for Stitch-Down Shoe Production

The TH-727A is specifically designed to accommodate the production of stitch-down shoes. Its features and capabilities align with the unique demands of this construction method, providing manufacturers with a reliable and efficient tool for producing high-quality stitch-down footwear.

Technical Specifications

-

Model: TH-727A

-

Power Supply: 220V / 50Hz

-

Applicable Materials: Fabric, Genuine Leather, Artificial Leather

-

Function: Heel Seat Lasting

-

Voltage: 220V

-

Certification: GS, RoHS

-

Condition: New

-

Origin: Taizhou, Zhejiang

-

Production Capacity: 500 Sets/Month

Applications

The TH-727A is ideal for manufacturers specializing in:

-

Stitch-Down Footwear: Its design caters to the specific requirements of stitch-down shoe construction.

-

Various Upper Materials: Compatible with fabric, genuine leather, and artificial leather, offering versatility in production.

-

Custom and Small Batch Production: The machine's adjustable features make it suitable for custom designs and small-scale manufacturing.

Advantages

-

Enhanced Precision: Adjustable components ensure accurate positioning and consistent results.

-

Improved Efficiency: The chain-like wrapping method and integrated heating device streamline the lasting process.

-

Versatility: Suitable for a range of materials and shoe designs, including stitch-down construction.

-

User-Friendly Operation: Designed with the operator in mind, offering intuitive controls and easy adjustments.

The TH-727A Heel Seat Lasting Machine stands out as a reliable and efficient solution for modern shoe manufacturing. Its advanced features, adaptability, and focus on quality make it an excellent choice for producers aiming to enhance their production capabilities and deliver superior footwear products.

No posts found