AUTOMATIC GENERALLY HYDRAULIC SOLE ATTACHING MACHINE TH-715A

MACHINE NAME: AUTOMATIC GENERALLY HYDRAULIC SOLE ATTACHING MACHINE

MODEL NO: TH-715A

BRAND: TENGHONG

FEATURES

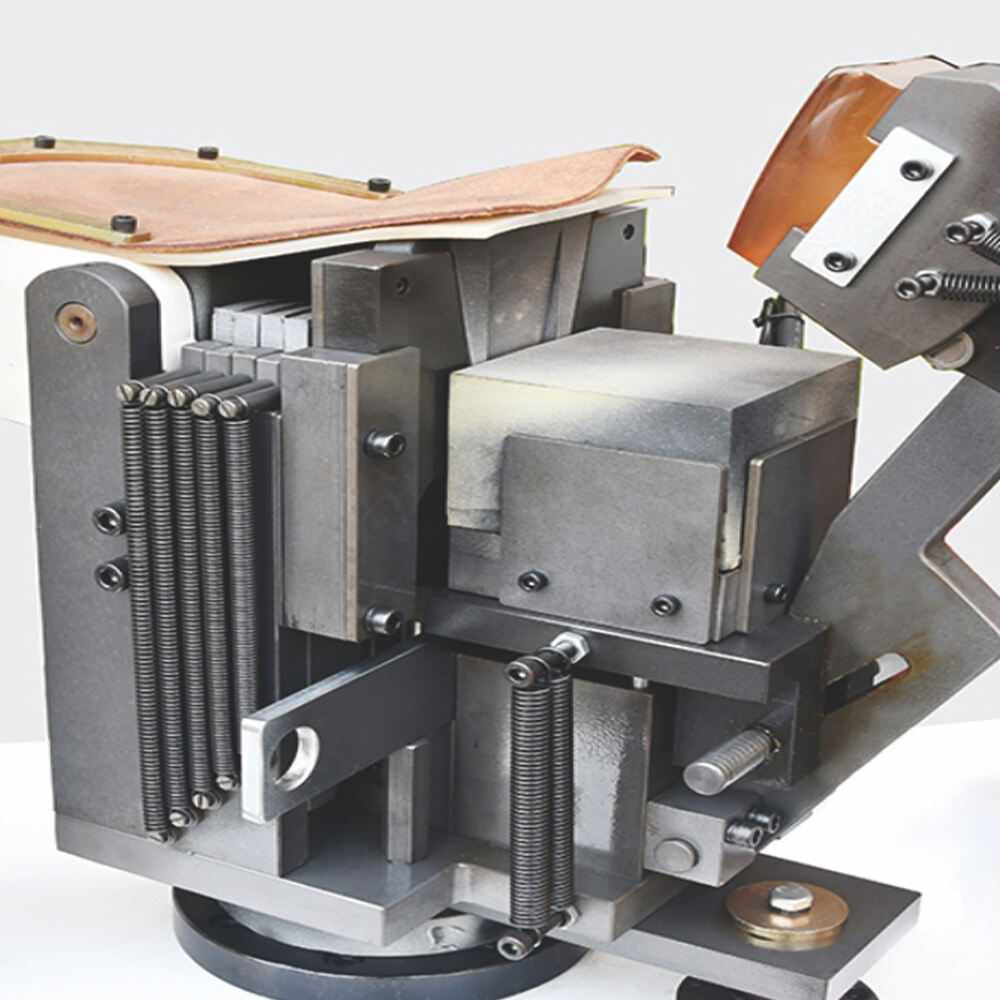

- Heavy-duty Walled Sole Attaching Machine

- The machine adopts a full hydraulic system design, suitable for dragon boat soles, wall-type wrapped soles sports shoes, casual shoes and other shoes with wrapped edges or toes. It can complete bottom pressing, edge pressing and front and back pressing at once or individually. It has a large output, strong adhesion, saves labor and provides even pressing with good result.

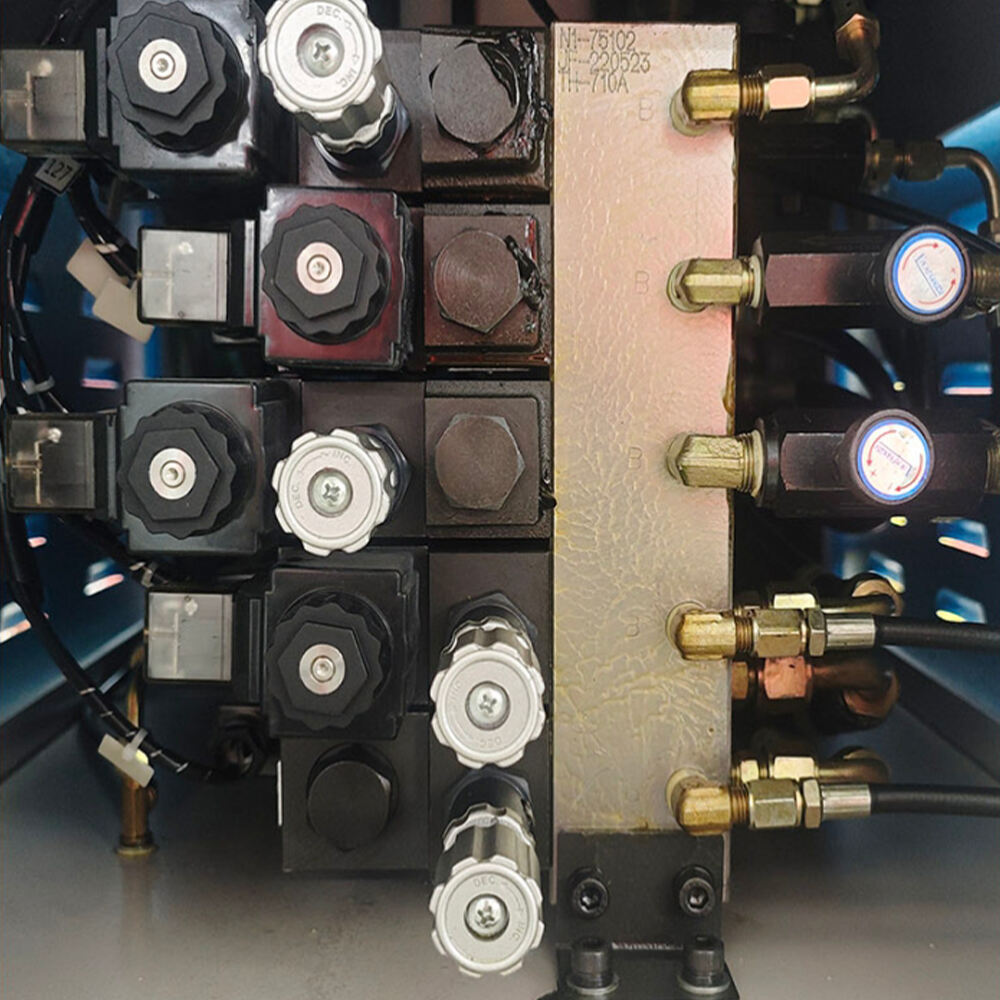

- Each movement of the machine has a pressure adjustment function.

- The machine is suitable for wall-type sole pressing of shoes with a last width between 140mm, length between 130mm and 400mm, height below 190mm, and sole edge height below 80mm, such as boat shoes and casual shoes.

TECHNICAL PARAMETER

- Pieces of side pressing blocks : 8

- Height of side pressing blocks : 80mm

- Adjustment of distance of band : 2 sections

- Power of Pump : 2.2kw

- Oil pressure : 40kg/m3

- Net weight : 430kg

- Dimension : 97x75x145cm

The TH-715A Automatic Generally Hydraulic Sole Attaching Machine is engineered for high-volume footwear manufacturing, offering precision, efficiency, and adaptability across various shoe types. Below is a comprehensive overview of its features, operational mechanics, and suitability for different production environments.

Hydraulic Precision Pressing System

The TH-715A employs a fully hydraulic system, ensuring consistent and uniform pressure application during the sole attaching process. This hydraulic mechanism minimizes manual intervention, reduces operator fatigue, and enhances the overall quality of the finished product.

Adjustable Pressing Mechanism

Equipped with adjustable front and rear pressing rods, the machine can accommodate shoes of varying heel heights and sizes. This flexibility makes it suitable for attaching soles to both men's and women's footwear, including high heels and athletic shoes.

High Production Capacity

Designed for efficiency, the TH-715A boasts a production capacity of approximately 2,500 pairs per 8-hour shift, making it ideal for medium to large-scale manufacturing operations.

User-Friendly Interface

The machine features a straightforward control panel, allowing operators to easily set pressing times and adjust settings. Its intuitive design reduces the learning curve and minimizes the likelihood of operational errors.

Durable Construction

Built with robust materials, the TH-715A ensures longevity and reliability. Its sturdy frame and components are designed to withstand the rigors of continuous operation in demanding production environments.

Technical Specifications

-

Power Supply: 380V, 50Hz

-

Motor Power: 1.5 kW

-

Hydraulic Oil Capacity: Approximately 90-100 liters of 68# or 46# hydraulic oil

-

Oil Pressure Range: 30–50 kg/cm²

-

Production Capacity: 2,500 pairs per 8-hour shift

-

Dimensions: 1080 mm (W) x 780 mm (D) x 1980 mm (H)

-

Weight: Approximately 800 kg

Operational Workflow

-

Setup: Connect the machine to a 380V power source and fill the hydraulic tank with the recommended oil.

-

Adjustment: Place the shoe last into the machine and adjust the front and rear pressing rods to align with the shoe's specifications.

-

Operation: Activate the machine using the control panel, initiating the hydraulic pressing cycle.

-

Completion: Once the cycle is complete, remove the finished shoe and prepare for the next unit.

Applications

The TH-715A is versatile and can be utilized in various footwear manufacturing sectors, including:

-

Sports Footwear: Attaching durable soles to running shoes and sneakers.

-

Casual Footwear: Assembling soles on everyday shoes and sandals.

-

Formal Footwear: Precision sole attachment for dress shoes and boots.

Advantages

-

Consistency: The hydraulic system ensures uniform pressure, leading to consistent sole attachment quality.

-

Efficiency: High production capacity reduces manufacturing time and increases throughput.

-

Adaptability: Adjustable settings allow for customization to different shoe types and sizes.

-

Ease of Use: The user-friendly interface simplifies operation and reduces training time.

The TH-715A Automatic Generally Hydraulic Sole Attaching Machine stands out as a reliable and efficient solution for footwear manufacturers seeking to enhance their production capabilities. Its combination of hydraulic precision, adjustable features, and high throughput makes it a valuable asset in modern shoe production lines.

No posts found