PLC Control Mini Heavy-duty Walled Sole Attaching Machine(16 side pressure rubber) TH-710EU

The modern footwear manufacturing industry demands machines that combine precision, efficiency, flexibility, and reliability. The TH-710EU PLC Control Mini Heavy-duty Walled Sole Attaching Machine represents an advanced technological solution tailored specifically for shoe manufacturers who focus on wall-type sole attachment, including dragon boat soles, sports shoes with wrapped edges, casual footwear, and other varieties requiring meticulous sole bonding. This machine’s compact design makes it an ideal fit for manufacturers with limited factory floor space, without compromising on the robustness or the functionality expected of heavy-duty industrial equipment. Powered by a full hydraulic system and controlled through an intuitive PLC (Programmable Logic Controller) interface displayed on a computer screen, the TH-710EU offers precise control over all pressing actions—bottom pressing, edge pressing, and front and back pressing—whether executed simultaneously or independently. Its 16 side pressure rubber blocks exert even, balanced pressure from all directions, ensuring a strong, durable bond with minimal labor input and consistent high-quality results.

Advanced PLC Control System and User Interface

One of the defining features of the TH-710EU is its incorporation of a PLC control system with a computer screen interface. This modern control mechanism enables operators to set, monitor, and adjust pressing parameters with ease and accuracy. The PLC controller ensures the machine operates under precise timing sequences and pressure settings, delivering consistent and repeatable results with minimal human error.

The computer screen display provides a user-friendly interface that allows operators to:

-

Select pressing modes (combined or individual pressing actions).

-

Adjust the pressing pressure for different parts of the shoe.

-

Monitor operational status and receive alerts for maintenance or faults.

-

Quickly change production settings to accommodate different shoe types or sizes.

This digital control capability modernizes the sole-attaching process, enhancing efficiency and reducing downtime caused by manual adjustments or operator errors.

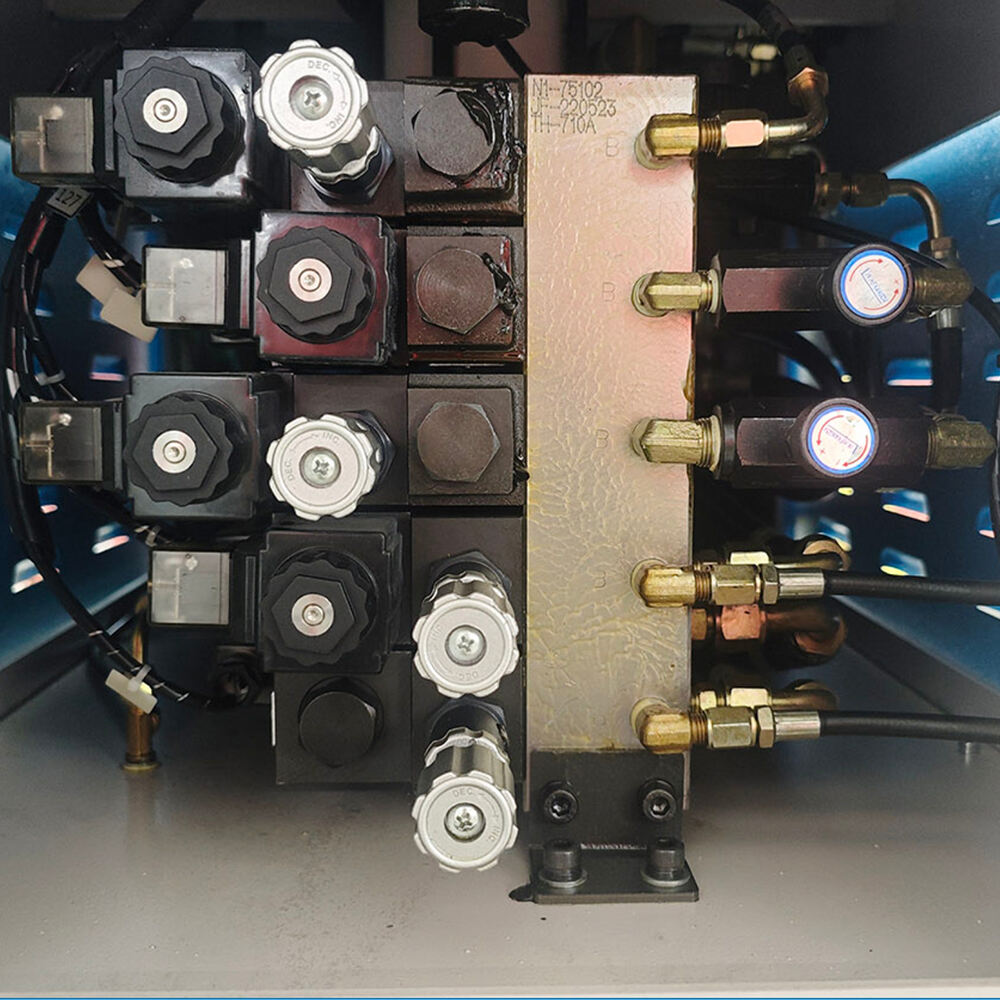

Hydraulic System Design for Superior Performance

The TH-710EU employs a full hydraulic system, which is fundamental to its ability to apply strong, uniform pressure essential for durable sole bonding. The hydraulic pump, driven by a 1.5 kW motor, delivers oil pressure rated at 40 kg/m³, enabling the machine to produce a pressing force that ensures a secure adhesion between the sole and the shoe upper.

Hydraulics offer several advantages in sole-attaching machinery:

-

Consistent Pressure: Hydraulic cylinders provide a smooth, continuous force that is easily adjustable and stable throughout the pressing cycle.

-

Durability and Reliability: Hydraulic systems are robust and have fewer mechanical parts subject to wear, reducing maintenance requirements.

-

Energy Efficiency: The system’s design optimizes oil flow and pressure, minimizing energy consumption while maintaining high output.

The combination of PLC control and hydraulic power in the TH-710EU results in a machine that is both technologically advanced and industrially rugged, ready to handle demanding production schedules.

Compact and Space-saving Design

The TH-710EU’s compact footprint distinguishes it in the heavy-duty sole-attaching machine market. Measuring approximately 100 cm in length, 63 cm in width, and 196 cm in height, the machine fits comfortably into small to medium-sized production areas. This space-saving feature is crucial for manufacturers who need to maximize floor efficiency or operate in constrained environments. Despite its small size, the machine does not sacrifice operational power or versatility. Its well-engineered construction allows it to deliver the same high adhesion strength and pressing uniformity as larger models, making it an excellent choice for workshops and factories where space is at a premium but production quality must remain uncompromised.

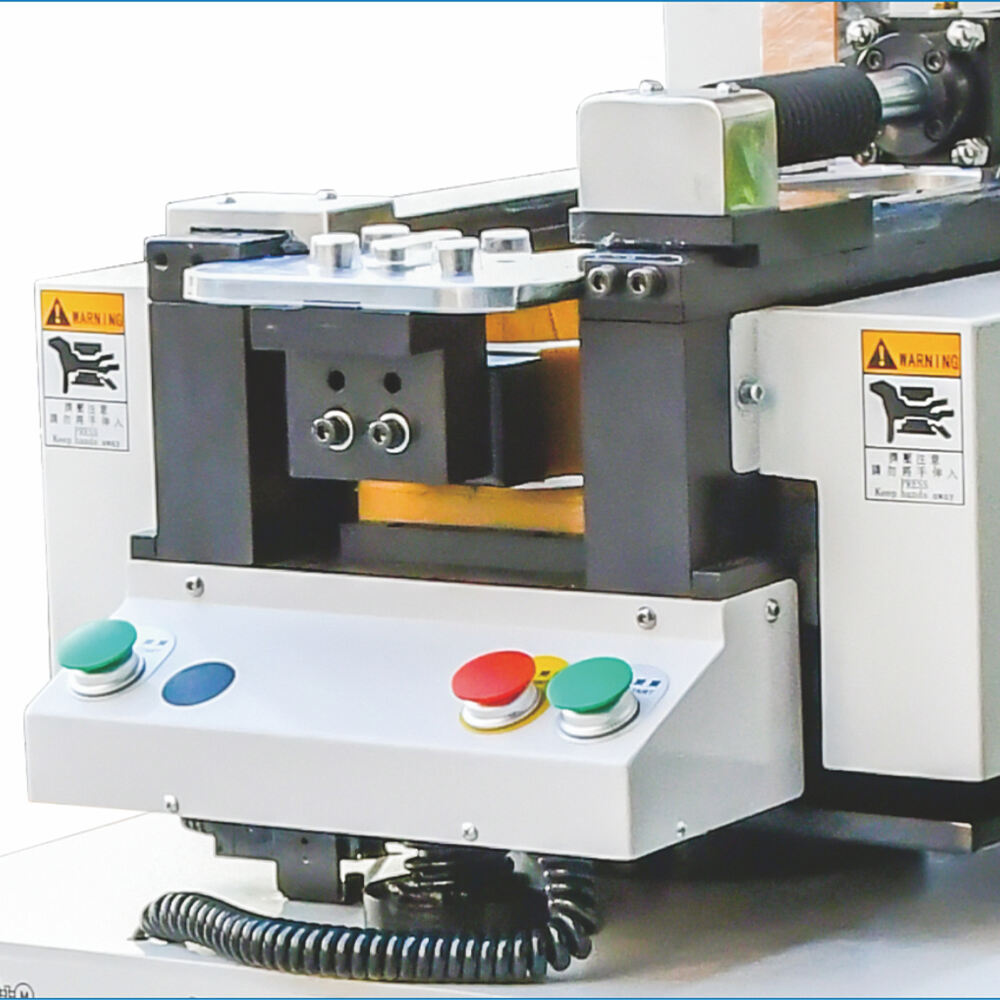

Multi-directional Pressing with Balanced Side Pressure Blocks

A standout feature of the TH-710EU is its 16 (or optionally 24) side pressure rubber blocks, each 80 mm in height. These blocks are strategically positioned to press the sole’s edges uniformly from all directions, crucial for shoes with wrapped edges or toes, such as dragon boat soles or wall-type soles. The machine includes an automatic balancing mechanism for the left and right feet pressing blocks, ensuring that pressure is evenly distributed regardless of minor variations in shoe shape or size. This automatic balance facilitates better molding and prevents uneven compression or sole deformation, which can compromise shoe appearance and structural integrity . The multi-directional pressing capability means that manufacturers can trust the TH-710EU to consistently produce well-molded soles with strong edge bonds, improving both the durability and the aesthetic quality of the final product.

Flexibility in Pressing Operations

The TH-710EU provides versatile pressing operation modes to suit different production needs:

-

Simultaneous Pressing: Bottom pressing, edge pressing, and front and back pressing can be performed at once, maximizing cycle efficiency and throughput.

-

Individual Pressing: Each pressing action can also be executed independently, allowing operators to focus on specific parts of the sole attachment process or to accommodate shoes with unique bonding requirements.

This flexibility is particularly beneficial when dealing with a wide variety of shoe designs, materials, and sizes. Whether the shoe sole requires a comprehensive pressing cycle or only partial bonding, the TH-710EU adjusts accordingly, optimizing both time and energy.

Adjustable Pressure Control for Precision Bonding

Every movement of the machine incorporates a pressure adjustment function, allowing operators to fine-tune the pressing force according to the specific characteristics of the shoe being processed. The pressure adjustment handle is conveniently located at the front of the machine table, enabling easy access and quick modifications without interrupting the workflow.

This capability is essential for dealing with different sole materials, adhesives, and shoe constructions, as some require more pressure to achieve an optimal bond while others may need gentler handling to avoid damage.

Operators can calibrate:

-

Pressure for the sole bottom pressing.

-

Pressure for edge pressing.

-

Pressure for front and back pressing.

Such granular control ensures the machine can adapt to a broad spectrum of products, increasing its versatility and value on the factory floor.

Compatibility with Shoe Sizes and Types

The TH-710EU is designed to accommodate a range of shoe dimensions typical of many popular footwear categories. It is especially suited for wall-type sole pressing of shoes that meet the following specifications:

-

Last Width: Between 140 mm

-

Last Length: Between 130 mm and 400 mm

-

Shoe Height: Below 190 mm

-

Sole Edge Height: Below 80 mm

These dimensional ranges cover a wide variety of footwear, including:

-

Dragon Boat Shoes: Specialized soles designed for water resistance and a strong grip.

-

Sports Shoes: Athletic shoes that require secure sole adhesion to maintain performance and durability.

-

Casual Shoes: Everyday footwear that demands a balance of comfort, style, and longevity.

-

Boat Shoes: Shoes with wrapped edges that need precise, uniform edge pressing to prevent water ingress and sole detachment.

This broad compatibility makes the TH-710EU suitable for manufacturers producing diverse shoe types and sizes on the same production line.

Ergonomics and Operator-Friendly Features

Operator comfort and ease of use are key considerations in the TH-710EU design. The positioning of controls and handles ensures minimal operator strain during adjustments or machine setup. The machine's compact footprint also allows for convenient operator access, reducing fatigue and increasing productivity.

The PLC interface provides clear instructions and feedback, minimizing training time and reducing the potential for operator error.

Robust Build and Long-Term Reliability

Constructed with high-quality materials and components, the TH-710EU is built to withstand the daily demands of industrial footwear manufacturing. Its net weight of approximately 513 kilograms reflects its solid frame and hydraulic components, which contribute to machine stability during operation. The full hydraulic system, combined with the advanced PLC control, ensures that the machine operates smoothly over long production cycles with minimal downtime. Maintenance is straightforward, with accessible parts and clear monitoring through the PLC system, allowing for timely intervention to keep the machine running at peak efficiency.

Industry Applications and Use Cases

The TH-710EU excels in various footwear production environments:

-

Mass Production Facilities: Its high throughput and automated features make it ideal for large-scale manufacturing.

-

Specialty Footwear Workshops: The machine’s ability to handle dragon boat soles and wrapped edges suits niche markets with specialized shoe designs.

-

OEM and Private Label Manufacturers: Its flexibility allows manufacturers to switch between models efficiently, supporting diverse product lines.

-

Small to Medium Enterprises: The compact size and cost-efficiency make it accessible for manufacturers looking to upgrade production without major capital investment.

Workflow Integration and Production Efficiency

In a typical production line, the TH-710EU integrates seamlessly with upstream and downstream processes:

-

Upstream: Shoes and soles prepared with adhesive can be fed into the machine by operators or automated material handling systems.

-

Within Machine: The PLC system controls the pressing cycle precisely, reducing cycle times and increasing repeatability.

-

Downstream: Finished shoes exit the machine ready for cooling, trimming, or further assembly steps.

This integration optimizes overall factory throughput and product quality.

Environmental and Energy Considerations

The TH-710EU’s efficient hydraulic system minimizes energy consumption relative to its output power, supporting environmentally responsible manufacturing. The machine’s oil system is designed for minimal leakage and easy maintenance, further contributing to sustainability efforts in factory operations.

The TH-710EU PLC Control Mini Heavy-duty Walled Sole Attaching Machine is a state-of-the-art industrial machine designed to meet the rigorous demands of modern shoe manufacturing. Its advanced PLC control, full hydraulic system, compact footprint, and versatile pressing capabilities make it a highly efficient and reliable solution for attaching wall-type soles with wrapped edges. Manufacturers will benefit from its high adhesion strength, labor-saving automation, precise pressure control, and ability to handle a broad range of shoe types and sizes. The TH-710EU stands as an essential investment for factories aiming to improve production quality, increase throughput, and maintain a competitive advantage in the footwear market.

No posts found