DOUBLE STATION HEAVY-DUTY WALLED SOLE ATTACHING MACHINE(16 SIDE PRESSURE RUBBER) TH-710E

MACHINE NAME: DOUBLE STATION HEAVY-DUTY WALLED SOLE ATTACHING MACHINE(16 SIDE PRESSURE RUBBER)

MODEL NO: TH-710E

BRAND: TENGHONG

FEATURES

- Automatic Generally Hydraulic Sole Attaching Machine

- The machine employs the oil pressure function. The pressure is strong and the adherence is very solid.

- The grades adhered in the front shoes can be automatically adjusted.

- The female shoes can be adhered with the heels of shoe of any height.

- The male shoes can be adhered with any size.

TECHNICAL PARAMETER

- Model : TH-710E

- Power of pump : 1.5Kw

- Oil Pressure : 50Kg/m3

- Machine Dimension : 105x80x192cm

- N.W./G.W. : 629Kg

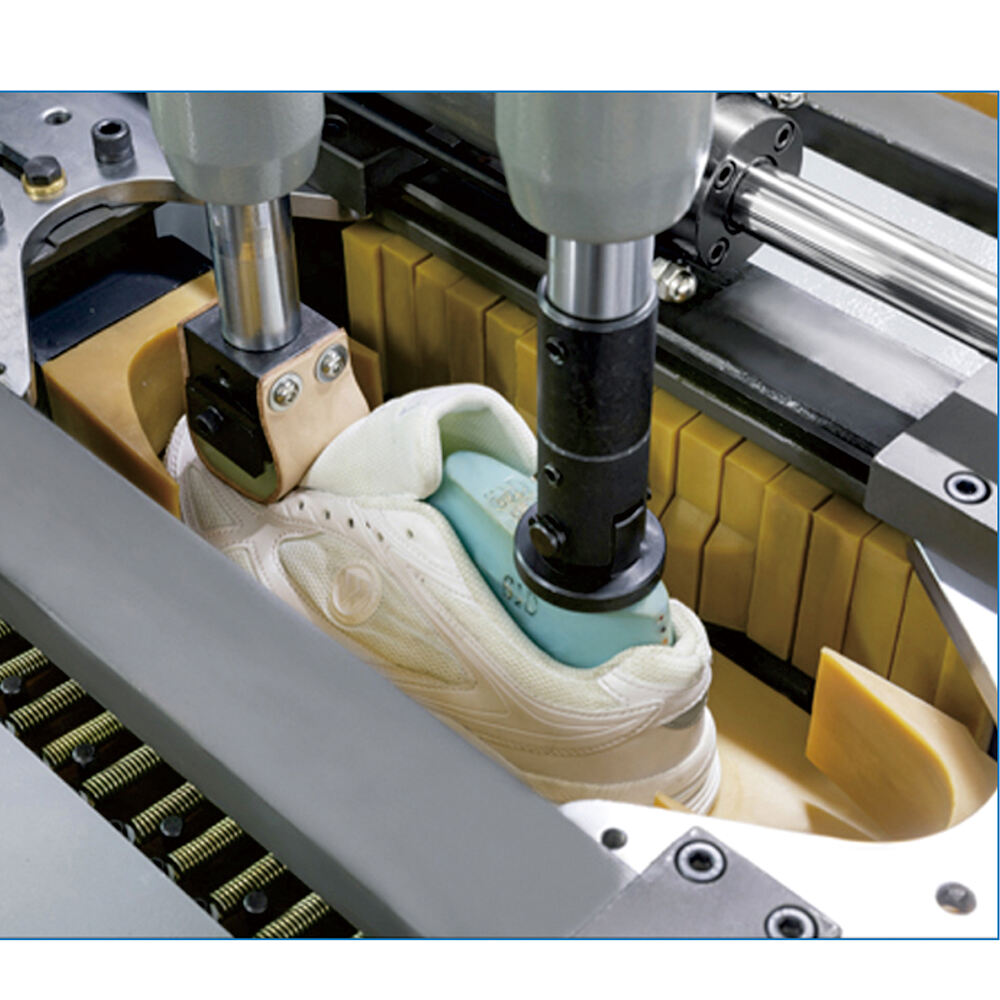

In the footwear manufacturing industry, the efficiency and quality of sole attachment are crucial determinants of a shoe’s durability and consumer satisfaction. The TH-710E Double Station Heavy-duty Walled Sole Attaching Machine stands as a testament to engineering innovation, designed to meet the high demands of modern shoe production. This machine leverages the power of hydraulic oil pressure to achieve exceptional bonding strength and consistency, making it an ideal solution for manufacturers specializing in wall-type sole attachment for both male and female footwear. With the incorporation of advanced hydraulic technology, the TH-710E ensures a firm, uniform adherence of soles to shoe uppers. The machine’s double-station design enhances production throughput by allowing simultaneous processing of two pairs of shoes, thereby significantly increasing manufacturing efficiency. Equipped with sixteen side pressure rubbers, this model guarantees a comprehensive edge pressing force that secures the sole firmly across its entire perimeter, an essential feature for shoes with wrapped edges or specialized heel designs.

Powerful Hydraulic Oil Pressure System

At the core of the TH-710E’s operation is its oil pressure function, which applies a strong, uniform force to the sole and shoe upper. This hydraulic system delivers consistent pressure throughout the pressing cycle, ensuring that adhesive layers bond securely. The use of hydraulic power as opposed to pneumatic or mechanical alternatives offers numerous benefits, including more precise force control, greater durability, and reduced mechanical wear. The machine’s hydraulic pump, powered by a 1.5 kW motor, delivers an oil pressure of 50 kg/m³, generating a pressing force sufficient to adhere a variety of sole materials to different shoe types. This high-pressure capability is vital for ensuring that the sole adheres firmly to the shoe, resulting in footwear that can withstand daily wear and tear without the sole detaching prematurely.

Double Station Design for Enhanced Productivity

Unlike single-station machines, the TH-710E features a double-station configuration, which means it can process two shoes at the same time. This dual operation capability significantly boosts production capacity, allowing manufacturers to double their output without requiring additional floor space or labor resources. Each station is equipped with sixteen side-pressure rubber blocks that distribute pressing force evenly along the sole edges. This extensive edge pressing is essential for maintaining the shape and structural integrity of the sole, especially for walled or wrapped sole designs that require meticulous bonding along every perimeter. The double station setup is particularly beneficial in high-volume manufacturing settings where speed and consistency are crucial, such as factories producing sports shoes, casual footwear, and specialized boat shoes.

Automatic Adjustment for Front Shoe Grades

One of the innovative features of the TH-710E is its ability to automatically adjust the grades adhered to the front part of the shoe. This functionality allows the machine to adapt to various shoe sizes and styles dynamically without manual recalibration by operators for every different shoe model. Automatic adjustment improves efficiency by reducing setup times and minimizing human error. It also enables manufacturers to produce a diverse range of shoes on a single production line, seamlessly switching between models with different front shoe dimensions while maintaining consistent quality.

Versatility for Both Male and Female Shoes

The TH-710E caters to a broad range of shoe designs, capable of adhering female shoes with heels of any height and male shoes of any size. This adaptability makes it highly versatile for footwear manufacturers who produce gender-specific designs or mixed production batches. For female shoes, where heel height can vary significantly, the machine’s hydraulic pressure system ensures reliable adhesion regardless of heel dimensions. For male shoes, which can range widely in size, the machine’s adjustable mechanisms accommodate varying last sizes without compromising the strength or uniformity of the sole attachment. This flexibility is essential in contemporary footwear production, where rapid market changes and consumer preferences demand manufacturing systems that can handle diverse product specifications without extensive downtime.

Robust and Durable Construction

The TH-710E is constructed with heavy-duty materials designed for industrial use. Its sturdy frame and components are engineered to withstand the rigors of continuous operation in factory environments. The net weight of 629 kilograms reflects the solid build quality and stability required for precise hydraulic pressing operations. The machine’s size, measuring 105 cm in length, 80 cm in width, and 192 cm in height, allows it to fit comfortably into typical manufacturing spaces without sacrificing operator accessibility or safety.

Technical Specifications and Performance Parameters

The TH-710E is engineered for optimal performance, combining a powerful hydraulic system with precise mechanical components:

-

Model: TH-710E

-

Power of Pump: 1.5 kW

-

Oil Pressure: 50 kg/m³

-

Net Weight: 629 kg

-

Dimension: 105 cm (L) × 80 cm (W) × 192 cm (H)

-

Side Pressure Rubber Blocks: 16 pieces

The oil pressure capacity is particularly noteworthy, providing a level of force that ensures a secure bond even for challenging sole materials and complex shoe designs.

Operational Workflow

The TH-710E is designed to deliver smooth and efficient operation from start to finish, minimizing manual intervention and maximizing consistency.

-

Shoe Preparation: Prior to pressing, shoes and soles are prepared with appropriate adhesives. The process requires careful application of glue, ensuring complete coverage on bonding surfaces.

-

Loading: The operator loads pairs of shoes onto the two pressing stations, aligning each shoe precisely to ensure even pressure distribution during the cycle.

-

Program Selection and Setup: Depending on the shoe model and production requirements, the operator selects preset parameters for pressure, pressing time, and other relevant settings. Automatic adjustment functions facilitate rapid changeover between shoe types.

-

Pressing Cycle Initiation: Upon starting the machine, hydraulic cylinders engage and apply pressure through the 16 side pressure rubber blocks on each station. The oil pressure system delivers powerful, steady force to the sole and upper.

-

Edge and Sole Bonding: The machine applies pressure to the sole bottom and edges simultaneously, ensuring comprehensive adhesion around the shoe perimeter. This step is critical for wall-type soles that rely on full contact bonding to achieve structural integrity.

-

Cycle Completion and Unloading: Once the pressing cycle completes, the machine releases pressure, and the operator removes the adhered shoes for inspection and further processing.

-

Quality Inspection: Manufacturers typically conduct visual and mechanical tests on the shoes to verify adhesion quality, ensuring the soles are firmly attached without defects.

Advantages Over Conventional Sole Attaching Machines

The TH-710E offers several clear advantages over traditional mechanical or pneumatic sole-attaching equipment:

-

Higher Adhesion Strength: The hydraulic oil pressure system provides superior pressing force, resulting in more reliable sole-to-upper bonding.

-

Increased Throughput: The double station design effectively doubles production capacity without requiring additional floor space or labor.

-

Automatic Adjustment: Reduces setup times and operator errors, enabling fast transitions between different shoe models and sizes.

-

Wide Compatibility: Supports both female and male shoes with various heel heights and sizes, making it suitable for a diverse product range.

-

Robust Construction: Designed for long-term industrial use with minimal maintenance, offering high return on investment.

Applications Across the Footwear Industry

The TH-710E is well suited for manufacturers focused on high-quality, high-volume shoe production. Its primary application areas include:

-

Sports Footwear: Secure sole attachment for running shoes, trainers, and other athletic shoes where durability and comfort are vital.

-

Casual Shoes: Ideal for casual and lifestyle footwear requiring strong edge bonding to maintain aesthetics and functionality.

-

Boat Shoes and Outdoor Footwear: Where water resistance and sole durability are crucial, this machine ensures firm attachment capable of withstanding outdoor conditions.

-

Fashion and High-Heel Shoes: Its ability to adhere heels of varying heights reliably makes it suitable for women's fashion footwear, including heels and wedges.

-

OEM and Private Label Manufacturing: Manufacturers producing multiple brands can benefit from their flexibility and fast model changeover capabilities.

Industry Relevance and Market Trends

Footwear manufacturing is increasingly driven by the need for automation, precision, and versatility. The TH-710E aligns perfectly with these market demands by offering:

-

Automation: Reducing labor dependence and increasing consistency in product quality.

-

Precision Engineering: Delivering uniform pressure and adhesion that translates to longer-lasting footwear.

-

Flexibility: Enabling manufacturers to keep up with fast fashion cycles and diverse consumer preferences.

As consumers demand more durable, stylish, and comfortable shoes, machines like the TH-710E become essential tools for manufacturers aiming to maintain a competitive edge.

Operator Training and Safety Considerations

Efficient and safe operation of the TH-710E requires proper operator training focused on:

-

Machine setup and programming.

-

Loading and unloading procedures.

-

Routine hydraulic system maintenance.

-

Emergency stop protocols and machine safety features.

The machine includes safety guards and emergency stop buttons, ensuring that operator safety remains a top priority during all phases of operation.

Maintenance and Longevity

The TH-710E is engineered for durability but requires regular maintenance to maintain peak performance:

-

Hydraulic oil should be regularly checked and replaced to prevent system degradation.

-

Inspection of seals, hoses, and valves to detect wear or leaks.

-

Calibration of pressure settings to maintain accurate pressing forces.

-

Cleaning of pressing blocks to avoid contamination that might affect adhesion quality.

Proper maintenance extends machine life and ensures consistent product quality over time.

The TH-710E Double Station Heavy-duty Walled Sole Attaching Machine is an advanced, reliable, and efficient solution for modern footwear manufacturers. Its robust hydraulic system, combined with a double station design and extensive side pressure rubber blocks, delivers superior bonding strength and enhanced productivity. The automatic adjustment features and broad compatibility with different shoe styles make it a versatile asset for any footwear production line. Manufacturers investing in the TH-710E benefit from improved operational efficiency, reduced labor costs, and high-quality sole attachment that meets demanding industry standards. This machine represents a smart investment for those seeking to elevate their production capabilities and ensure customer satisfaction through durable, well-constructed footwear.

No posts found