PLC Control Single Station Heavy-duty Walled Sole Attaching Machine TH-710D

In today’s competitive footwear manufacturing industry, precision, efficiency, and reliability are paramount. The TH-710D PLC Control Single Station Heavy-duty Walled Sole Attaching Machine emerges as a state-of-the-art solution for manufacturers who demand high quality and consistent output in wall-type sole pressing processes. This machine exemplifies modern industrial automation with advanced PLC control and a full hydraulic system, delivering superior performance for attaching soles to a variety of shoe styles, including boat shoes, casual footwear, and sports shoes with wrapped edges or toes. Designed to meet the complex requirements of wall-type sole application, the TH-710D combines the efficiency of hydraulic mechanics with the sophistication of programmable logic controllers (PLC) and a user-friendly computer screen interface. This enables operators to achieve exact pressure settings and processing times, thus guaranteeing uniform sole attachment, strong bonding, and ultimately superior footwear quality.

Advanced PLC Control and Computer Screen Settings

At the heart of the TH-710D machine is an intelligent PLC system that controls every aspect of the sole-attaching process. Operators interact with the machine via a clear, easy-to-use computer screen interface that allows precise programming of pressing parameters such as pressure, time, and sequence. The automation reduces operator error and streamlines the workflow, providing consistent results across production batches. This computer-aided interface is designed to be intuitive, enabling operators of various skill levels to program the machine effectively. Multiple presets can be saved for different shoe types and sizes, facilitating rapid changeovers and minimizing downtime.

Full Hydraulic System Design

The TH-710D uses a robust full hydraulic system to apply uniform pressure across the sole and shoe upper. Unlike mechanical or pneumatic systems, the hydraulic design offers smooth, controlled force application with minimal fluctuations. This stability is crucial for maintaining the integrity of the adhesive bond between the sole and the shoe, preventing issues like sole separation or uneven pressing. The oil-based system also prolongs the lifespan of machine components by reducing wear and tear caused by repetitive mechanical impacts. Hydraulic components are typically quieter and require less maintenance, contributing to an overall more reliable production environment.

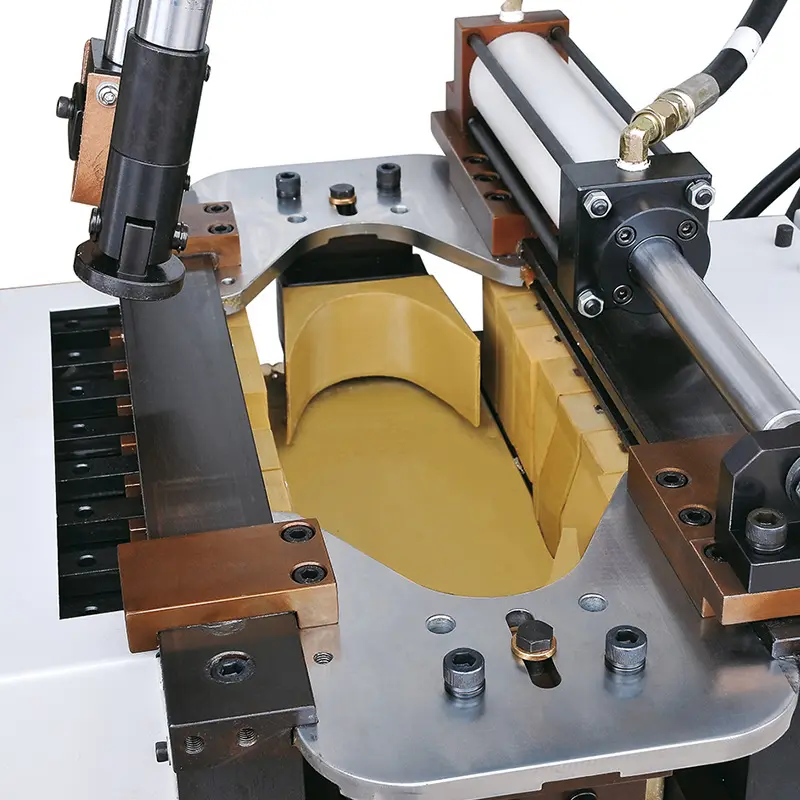

Suitability for Wall-Type Sole Pressing

This machine is specifically engineered to handle wall-type sole pressing operations—ideal for shoes with wrapped edges or toes, such as boat shoes, casual sneakers, and sports footwear. The design accommodates the unique demands of edge wrapping, ensuring the sole’s edges are securely bonded to the shoe upper for enhanced durability and aesthetics. The TH-710D can accommodate shoes with a last width of up to 140 mm, lengths ranging from 130 mm to 400 mm, height below 190 mm, and sole edge height under 80 mm, allowing it to handle a wide variety of shoe sizes and styles in a production line.

Multi-Function Pressing: Bottom, Edge, and Front/Back

A standout feature of the TH-710D is its capability to perform bottom pressing, edge pressing, and front/back pressing either simultaneously or independently. This flexibility allows manufacturers to optimize the pressing process according to the specific bonding requirements of each shoe model.

-

Bottom Pressing: Applies pressure directly to the shoe sole bottom to ensure full contact adhesion.

-

Edge Pressing: Focuses pressure on the sole edges for wrapping and bonding.

-

Front and Back Pressing: Applies additional pressing to the toe and heel areas, critical for shoes requiring reinforced bonding.

Being able to isolate these pressing functions improves quality control and adaptability for custom shoe designs.

Pre-Charge Valve to Accelerate Oil Cylinder Movement

The rising oil pressure cylinder incorporates a pre-charge valve system that supplements the oil volume during operation. This design innovation speeds up the rising action of the cylinder, effectively shortening the pressing cycle time and improving throughput. Faster cycle times are essential in high-volume manufacturing to meet tight production schedules without sacrificing quality. This feature reflects the machine’s emphasis on balancing speed with precision, ensuring manufacturers don’t need to compromise between efficiency and the quality of the bonding.

Adjustable Front and Back Band Mechanism

The machine’s front and back band mechanism can retreat with a controllable distance, allowing operators to adjust the machine to fit different shoe sizes quickly. This feature reduces the time and effort required to switch between shoe models of varying dimensions and accommodates production lines that need to handle multiple styles in small batches. The adjustment mechanism enhances the machine’s versatility and maximizes its utility in dynamic manufacturing environments.

Pressure Adjustment Function for Each Mechanical Action

Precision is critical in sole attaching, and the TH-710D allows for individual pressure adjustments for every pressing action. Operators can use conveniently located handles in front of the machine table to fine-tune the pressure according to the shoe material, sole thickness, and adhesive properties. This granular control ensures the best possible bonding strength while preventing damage to sensitive materials, such as thin rubber soles or delicate shoe uppers.

Technical Details

-

Model: TH-710D

-

Number of Side Pressing Blocks: 16 pieces

-

Height of Side Pressing Blocks: 80 mm

-

Adjustment of Band Distance: 2 sections

-

Power of Pump: 2.2 kW

-

Oil Pressure: 40 kg/m³

-

Net Weight: 430 kg

-

Dimensions: 97 cm (Length) × 75 cm (Width) × 145 cm (Height)

Operational Workflow

The TH-710D is designed to streamline the sole attaching process while maintaining strict quality standards.

-

Preparation: The operator first prepares the shoe by applying adhesive to the sole and upper as per the adhesive manufacturer’s instructions.

-

Placement: The shoe is placed securely on the machine platform, aligning it correctly under the pressing blocks.

-

Parameter Selection: Using the PLC-controlled touchscreen, the operator selects the appropriate program based on the shoe type, size, and required pressing profile.

-

Pressing Cycle Start: The operator initiates the pressing cycle. The machine’s hydraulic system engages the pressing blocks, applying uniform pressure to the sole and edges.

-

Pressing Sequence: Depending on the selected program, bottom pressing, edge pressing, and front/back pressing occur either in a simultaneous or sequential manner. The pre-charge valve accelerates the hydraulic cylinder’s action to reduce cycle time.

-

Pressure Adjustment: If necessary, the operator adjusts the pressure handles to fine-tune the force during pressing, accommodating different materials or adhesion properties.

-

Band Adjustment: The front and back band mechanisms can be retreated or extended to fit the shoe size perfectly, enabling quick product changeover.

-

Completion: Once the cycle finishes, the operator removes the bonded shoe for quality inspection and moves on to the next unit.

Advantages Over Traditional Machines

The TH-710D offers several benefits over traditional mechanical or pneumatic sole pressing machines:

-

Automation and Precision: PLC control combined with hydraulic pressure ensures precise, consistent pressing compared to manual or semi-automatic machines.

-

Speed and Throughput: The pre-charge valve and hydraulic system significantly reduce pressing cycle times, increasing production capacity.

-

Versatility: With adjustable pressing functions and band mechanisms, the TH-710D easily adapts to various shoe sizes and designs, minimizing downtime.

-

Durability and Maintenance: Hydraulic systems tend to be more durable and require less maintenance than mechanical components, reducing operational costs and machine downtime.

-

Ergonomics and Usability: Intuitive touchscreen and ergonomic pressure adjustment handles reduce operator fatigue and training time.

Applications and Suitability

The TH-710D is engineered for industries focused on producing shoes with wall-type soles, especially where precision and bonding strength are essential. Typical applications include:

-

Boat Shoes: These often have wrapped soles and require sturdy edge bonding for durability in wet environments.

-

Casual Footwear: Everyday wear shoes that need a strong sole attachment without compromising aesthetics.

-

Sports Shoes: Athletic footwear with advanced sole designs requiring firm and uniform pressing.

-

Custom and Boutique Shoes: Where small-batch production demands quick adjustment and precise control over pressing parameters.

Industry Impact and Market Position

The introduction of machines like the TH-710D marks a significant shift toward automation and precision in footwear manufacturing. By integrating advanced PLC control and hydraulic technology, this machine helps manufacturers stay competitive by:

-

Reducing reliance on skilled manual labor, which is often costly and variable.

-

Improving product quality with repeatable and controllable pressing parameters.

-

Increasing flexibility to respond to market demands for a wide range of shoe styles and sizes.

-

Enhancing production speed, allowing businesses to meet tighter deadlines and larger orders.

Operator Training and Safety

To maximize the machine’s benefits, operators should be trained in:

-

Navigating and programming the PLC interface.

-

Performing routine maintenance on hydraulic components.

-

Adjusting pressure settings based on material characteristics.

-

Understanding safety protocols, including emergency stops and proper shoe placement.

Safety features are incorporated into the TH-710D, such as emergency stop buttons and protective guards, to prevent accidents during operation.

Maintenance and Longevity

The TH-710D’s hydraulic system requires periodic checks, including:

-

Monitoring and replacing hydraulic oil to ensure smooth operation.

-

Inspecting seals and valves to prevent leaks.

-

Verifying pressure calibration for consistent pressing force.

-

Keeping the PLC software updated to benefit from the latest control algorithms.

Due to its robust construction and quality components, the machine delivers a long service life, making it a valuable asset for footwear manufacturers.

The TH-710D PLC Control Single Station Heavy-duty Walled Sole Attaching Machine represents a fusion of modern automation and durable mechanical design tailored for the demanding needs of today’s footwear industry. Its advanced PLC control system, combined with a reliable hydraulic pressing mechanism and flexible operational features, ensures manufacturers achieve high output with excellent bonding quality. Whether producing boat shoes, casual footwear, or sports shoes, this machine delivers uniform, strong sole attachments that meet exacting standards. With its ergonomic design and ease of use, the TH-710D not only boosts productivity but also improves workplace safety and operator comfort. Investing in the TH-710D means embracing a future-ready solution that enhances manufacturing capability, reduces labor costs, and supports high-quality footwear production in a competitive global market.

No posts found