HEAVY-DUTY WALLED SOLE ATTACHING MACHINE TH-710A

MACHINE NAME: HEAVY-DUTY WALLED SOLE ATTACHING MACHINE

MODEL NO: TH-710A

BRAND: TENGHONG

FEATURES

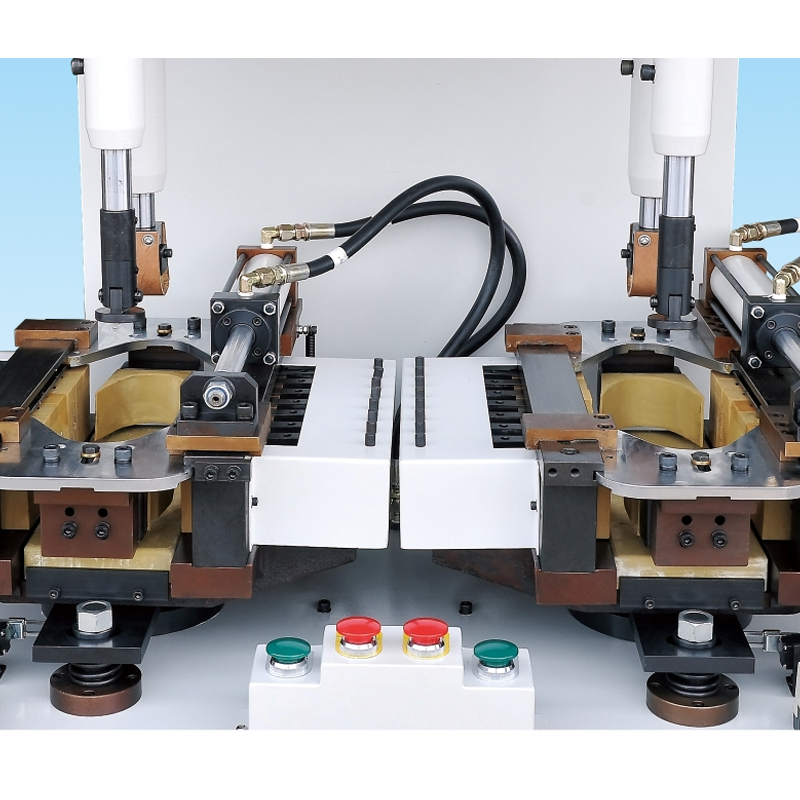

- The machine adopts a full hydraulic system design, suitable for dragon boat soles, wall-type wrapped soles sports shoes, casual shoes and other shoes with wrapped edges or toes. It can complete bottom pressing, edge pressing and front and back pressing at once or individually. It has a large output, strong adhesion, saves labor and provides even pressing with good result.

- Each movement of the machine has a pressure adjustment function.

- The machine is suitable for wall-type sole pressing of shoes with a last width between 140mm, length between 130mm and 400mm, height below 190mm, and sole edge height below 80mm, such as boat shoes and casual shoes.

TECHNICAL PARAMETER

- Model : TH-710A

- Pieces of side pressing blocks : 8

- Height of side pressing blocks : 80mm

- Adjustment of distance of band: 2 sections

- Power of Pump : 2.2kw

- Oil pressure : 40kg/m3

- Net weight : 430kg

- Dimension : 97x75x145cm

The TH-710A Heavy-duty Walled Sole Attaching Machine represents the pinnacle of modern shoe manufacturing technology, designed specifically for high-performance, precision, and efficiency in attaching walled soles. This machine is a robust solution built to meet the exacting demands of manufacturers producing a wide variety of footwear types, including sports shoes, casual footwear, boat shoes, and other styles requiring edge-wrapped soles or toe reinforcement. The machine’s full hydraulic system design guarantees powerful, uniform, and adjustable pressing force, providing consistent quality with every shoe produced. With its capacity to complete multiple pressing functions—bottom pressing, edge pressing, and front-back pressing—in a single cycle or separately, the TH-710A optimizes production workflows and saves valuable labor resources.

Key Features and Advantages

Full Hydraulic System Design for Heavy-Duty Performance

At the core of the TH-710A is a fully integrated hydraulic system engineered to deliver powerful and steady pressing force. This system enables:

-

Consistent Pressure Application: The hydraulic mechanism applies uniform pressure over the sole and shoe upper, ensuring excellent adhesion without damaging materials.

-

High Output Capacity: With strong hydraulic power, this machine handles thick, heavy soles such as dragon boat soles and wrapped edges efficiently.

-

Labor Saving: Automated hydraulic control reduces manual effort, minimizing operator fatigue and increasing production throughput.

-

Long Service Life: The durable hydraulic components ensure a machine lifespan suited to continuous heavy-duty factory use.

Multi-Function Pressing Capabilities

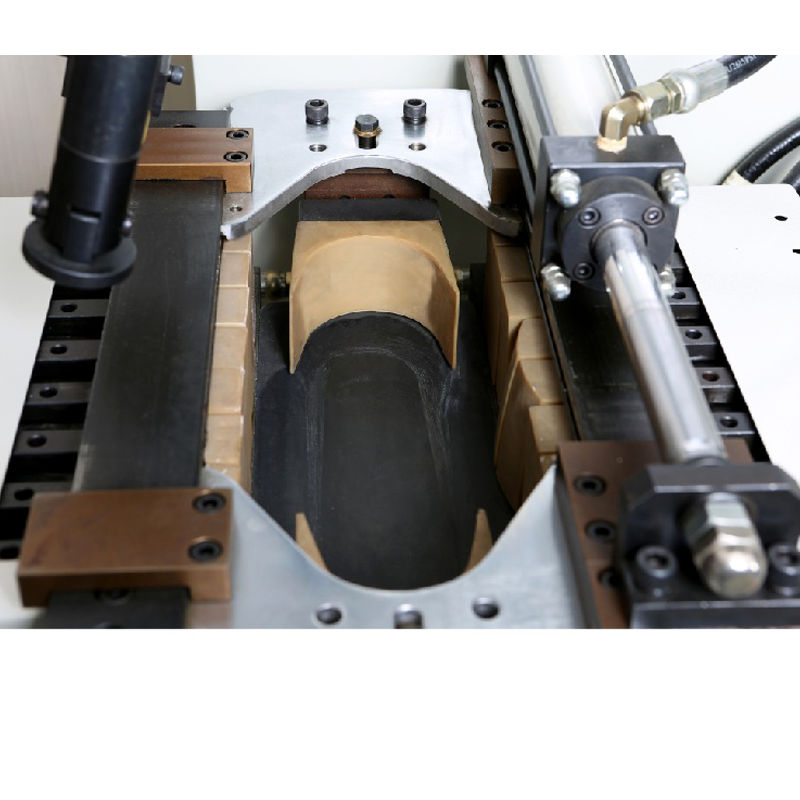

The TH-710A is designed to perform multiple types of pressing actions, which are crucial to the proper attachment of walled soles:

-

Bottom Pressing: Applies firm pressure to the entire sole base, ensuring the glue or adhesive bonds the sole securely to the shoe.

-

Edge Pressing: Applies precise pressure along the wrapped edge or wall of the sole, essential for styles like wall-type soles or boat shoes.

-

Front and Back Pressing: Targets the toe and heel areas individually or together, reinforcing critical high-stress points of the shoe for enhanced durability.

These pressing functions can be executed all at once or individually, giving manufacturers flexibility based on shoe design and production requirements.

Adjustable Pressure Control for Each Movement

Precision is paramount in shoe sole attaching, and the TH-710A offers pressure adjustment for each pressing movement. This feature allows operators to:

-

Tailor pressing force based on sole thickness, material type, and adhesive properties.

-

Protect delicate shoe materials by avoiding excessive pressure.

-

Optimize adhesion and pressing time to improve the final product’s comfort and longevity.

The ability to fine-tune pressure at multiple points ensures that each shoe meets exact quality standards.

Compatibility with a Wide Range of Shoe Sizes and Styles

This machine is suitable for wall-type sole pressing of shoes with specific dimensional parameters, making it ideal for manufacturers specializing in certain footwear categories:

-

Last width up to 140mm

-

Last length ranging from 130mm to 400mm

-

Last height up to 190mm

-

Sole edge height up to 80mm

These specifications cover a broad range of shoe types, including popular casual styles, boat shoes, and sporty wrapped-edge designs. The machine’s adaptability supports efficient production of different models without the need for extensive reconfiguration.

Robust Construction and Dimensions

Built to withstand the demands of industrial environments, the TH-710A features a solid and stable structure designed for longevity and reliability:

-

Weighing 430 kilograms, the machine remains securely fixed during operation, preventing vibration or displacement.

-

Its compact footprint (97 cm length × 75 cm width × 145 cm height) enables easy integration into various production line layouts without consuming excessive space.

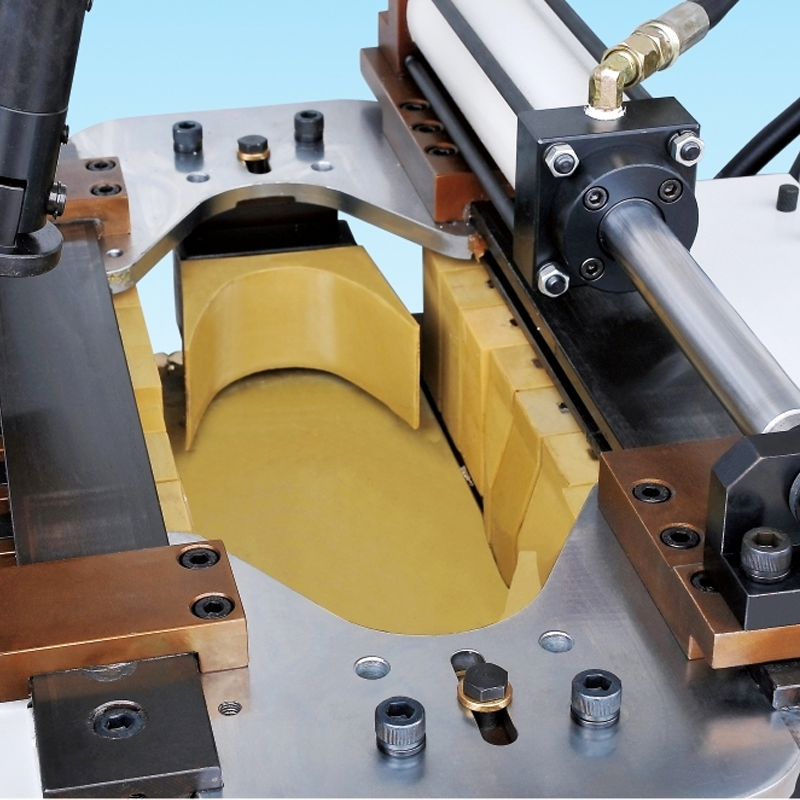

Technical Specifications for Optimal Operation

-

Pieces of Side Pressing Blocks: 8, designed to apply precise pressure evenly along the sole edges.

-

Height of Side Pressing Blocks: 80 mm, accommodating higher sole walls and wrapped edges.

-

Adjustment of Distance of Band: 2 sections, enabling customization of pressing width to match shoe sizes.

-

Power of Pump: 2.2 kW, providing sufficient hydraulic force for demanding pressing tasks.

-

Oil Pressure: 40 kg/m³, ensuring stable and controlled hydraulic pressure for consistent results.

In-Depth Analysis: How the TH-710A Operates

The TH-710A Heavy-duty Walled Sole Attaching Machine operates through a sophisticated blend of hydraulic mechanics and precision engineering, designed to improve manufacturing efficiency and shoe quality.

Preparation and Loading

The shoe, with the sole coated with adhesive or glue, is placed carefully on the machine's lasting platform. The operator selects the pressing mode based on the shoe style and production needs.

Hydraulic Activation and Pressing Cycle

Once activated, the hydraulic system controls multiple pressing blocks simultaneously:

-

The bottom pressing block compresses the sole against the shoe’s upper.

-

The side pressing blocks, typically eight in number, exert uniform pressure along the entire perimeter of the sole wall.

-

Additional pressing blocks at the front and back engage, targeting the toe and heel areas for complete coverage.

Because each pressing block’s pressure is individually adjustable, the machine ensures every part of the shoe receives optimal force.

Pressure Holding and Adhesion

The hydraulic system maintains pressure for a set period, which is critical for the adhesive to bond effectively. This duration can be customized based on the type of glue and shoe material to maximize adhesion strength.

Release and Removal

After the pressing cycle completes, the hydraulic pressure is safely released, and the shoe is removed for the next production step or quality inspection.

Applications and Industry Relevance

The TH-710A is engineered to fulfill the demands of various footwear manufacturers, offering significant advantages for production lines focusing on:

Sports Shoes and Casual Footwear

Sports shoes and casual styles frequently use wall-type or wrapped soles to improve aesthetics and durability. The TH-710A excels in handling these types of soles, delivering secure and even adhesion that withstands active use.

Boat Shoes and Nautical Footwear

Boat shoes, with their distinct wrapped edges and water-resistant soles, benefit greatly from the heavy-duty pressing and edge-reinforcing capabilities of this machine. The precision hydraulic pressure ensures soles are waterproof and firmly attached to prevent wear in wet conditions.

Custom Sole Designs and Thick-Edged Soles

Manufacturers producing thick-edged or dragon boat soles, which are typically more complex to press manually, gain significant labor savings and quality improvements by utilizing this machine’s advanced hydraulic system.

Operational Efficiency and Labor Savings

The TH-710A reduces manual labor by automating the pressing process with a powerful hydraulic system. This results in:

-

Faster Cycle Times: Automated, simultaneous pressing reduces production bottlenecks.

-

Consistent Quality: Automation minimizes human error, leading to fewer defects and rework.

-

Lower Labor Costs: Operators require less physical effort and can manage multiple machines, enhancing overall factory productivity.

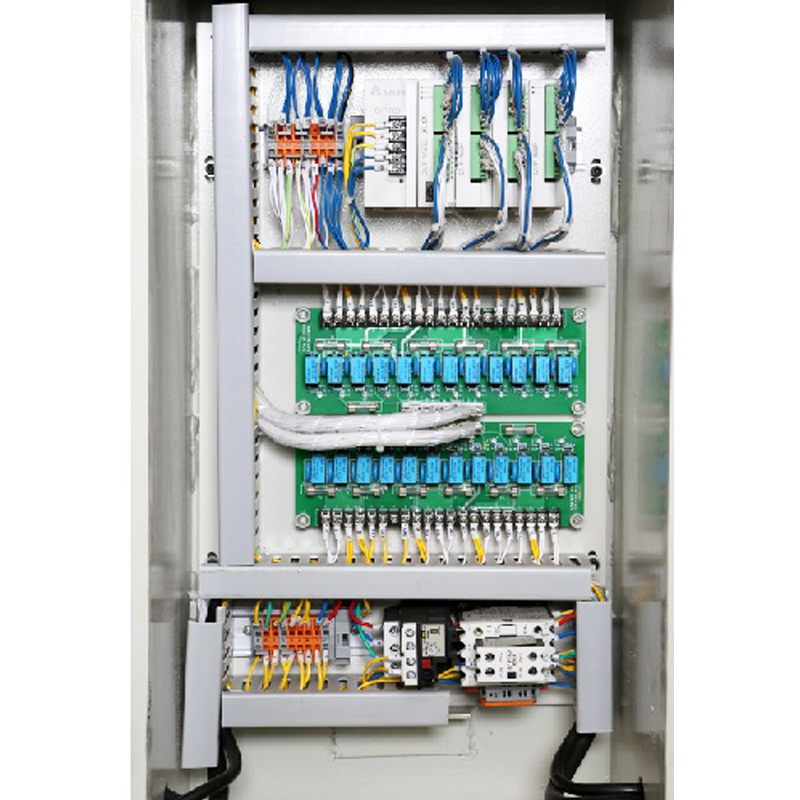

Maintenance and Durability

Durable Hydraulic Components

The machine’s hydraulic pump and cylinders are built from high-grade materials resistant to wear and corrosion, ensuring a long operational lifespan and minimal downtime.

Easy Pressure Adjustment

Operators can easily adjust the pressure for each movement, allowing routine calibration and maintenance without specialized tools.

Compact Design for Workspace Optimization

Despite its heavy-duty nature, the TH-710A’s design focuses on minimizing space usage, allowing manufacturers to optimize their shop floor layout.

Safety Considerations

Safety is integral to the TH-710A’s design:

-

Hydraulic pressure controls prevent accidental over-pressing.

-

Emergency stop features allow operators to halt the machine instantly.

-

Stable construction reduces machine vibration, preventing unintended movement during pressing.

Why Choose the TH-710A Heavy-duty Walled Sole Attaching Machine?

-

Precision Engineering: Ensures flawless adhesion and superior shoe quality.

-

Powerful Hydraulic System: Handles demanding soil types with ease.

-

Multi-Function Pressing: Provides versatility across shoe styles and production requirements.

-

User-Friendly Operation: Pressure adjustment and simple controls empower operators.

-

Durability and Longevity: Designed for continuous industrial use.

-

Production Efficiency: Improves throughput while reducing labor costs.

-

Safety Features: Protects workers and maintains operational safety standards.

For manufacturers committed to producing high-quality footwear with wrapped or wall-type soles, the TH-710A Heavy-duty Walled Sole Attaching Machine is an indispensable asset. Its combination of hydraulic power, multi-functional pressing capabilities, and precise control mechanisms ensures that every shoe leaving the production line meets the highest standards of adhesion, durability, and finish. From casual shoes to specialized boat shoes, this machine adapts seamlessly to a wide range of designs and materials, boosting production efficiency while maintaining product excellence. Its robust construction, ease of use, and safety features further position it as a leading choice for modern shoe factories seeking competitive advantage through technological advancement. Investing in the TH-710A means securing your manufacturing operations with a trusted, powerful, and efficient sole-attaching machine engineered for the demands of today’s dynamic footwear industry.

No posts found