COMPUTER MEMORY VISUAL LOCUS SERVO CONTROL SIDE & HEEL SEAT LASTING MACHINE TH-688MAS

MACHINE NAME: COMPUTER MEMORY VISUAL LOCUS SERVO CONTROL SIDE & HEEL SEAT LASTING MACHINE

MODEL NO: TH-688MAS

BRAND: TENGHONG

FEATURES

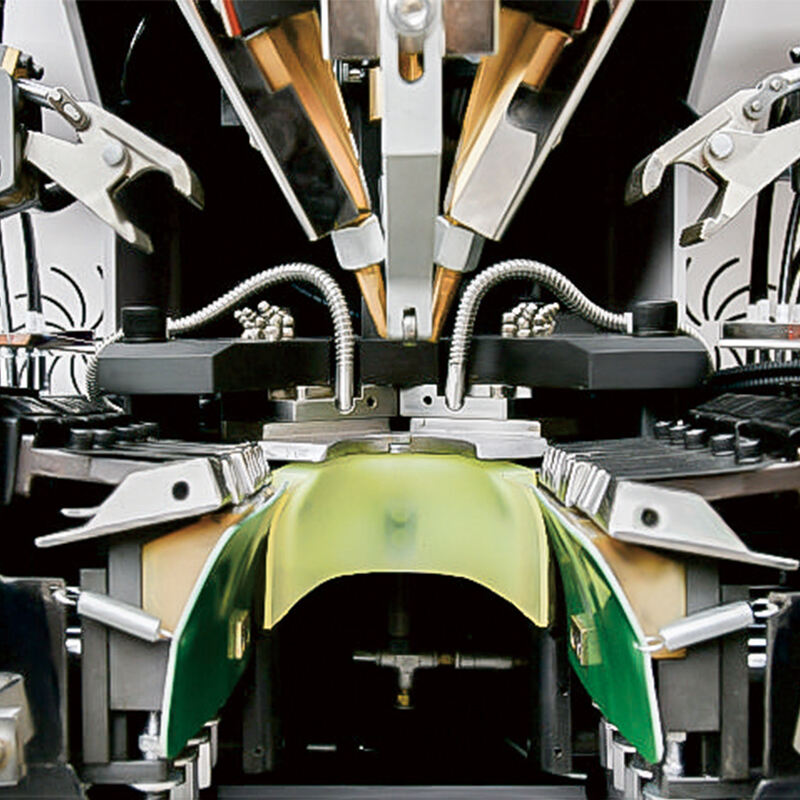

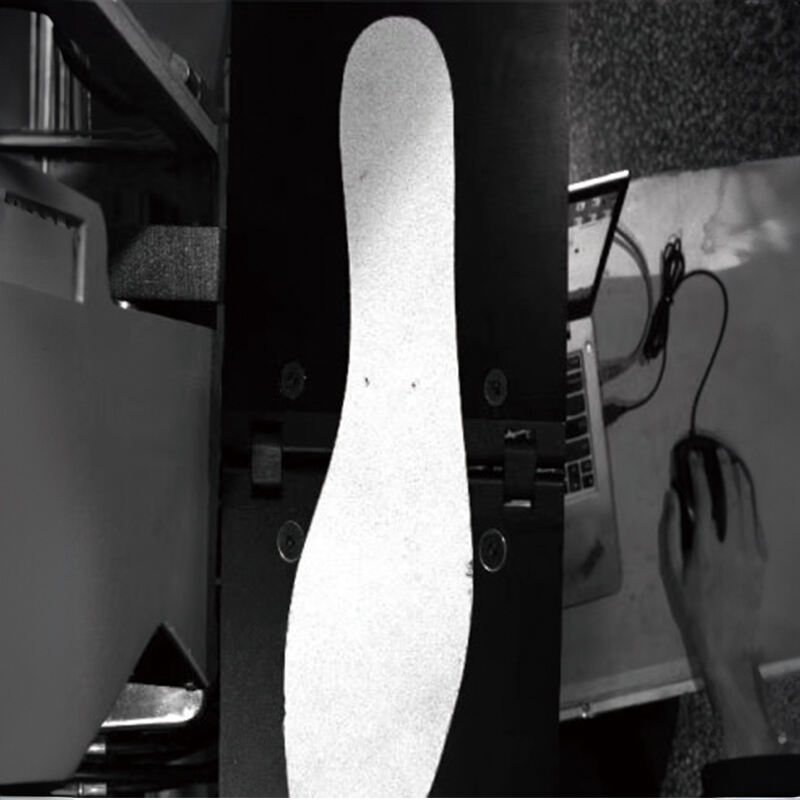

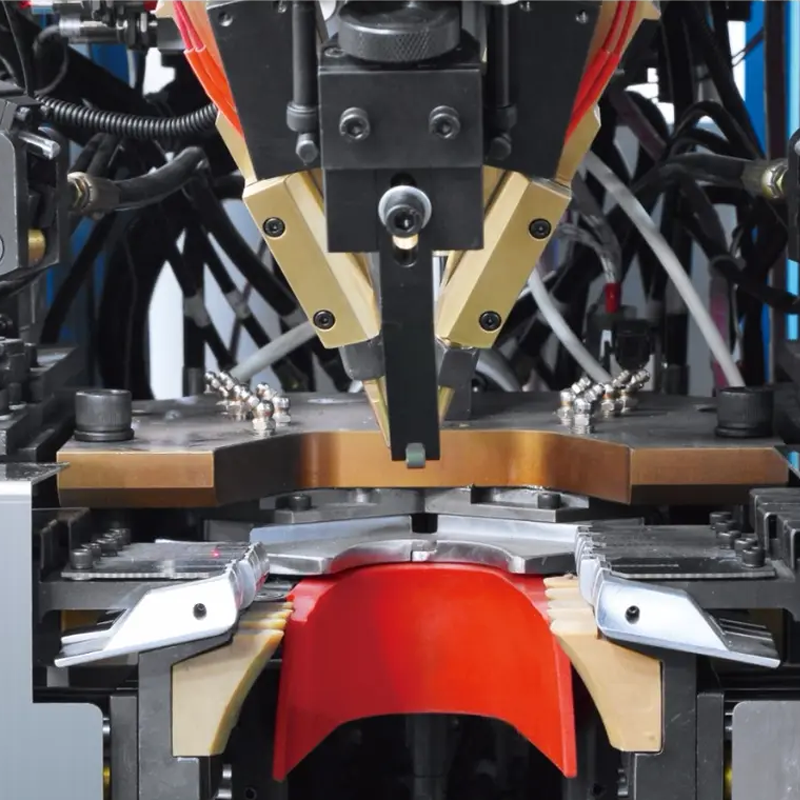

- This machine is using the most advanced visual identification technology to

format the cementing locus and four-axis servo-controlled cementing system to control two cement nozzles, by taking picture of the insole and and can quickly convert into a full set of sizes. - Program ability and Parameter Storage: (1) Programmable servo-controlled

cementing path; (2) The angle of side-pressing seat is controlled by motor-driven mechanism according to different height of waist, the angle of side-pressing seat can be memorized with automatic left/right swapping function to adjust the best lasting position; (3) Electric adjustment position memory of the front and rear paws, including the left and right Automatic switching of different clamping points on the inner and outer waist of the foot, the function of pulling the claws forward and inward, and then upward and forward (4) This machine can store at least 3000 sets of shoe shape memories. - The glue wiping stroke is adjusted by intuitive laser light irradiation point

adjustment. You only need to adjust the laser light point position to quickly adjust the required glue length. When the light point position is reached, the knot length can be set. - Pincers have both left/right-pulling, up-pulling and forward-pulling functions. The

position of up-pulling of inner and outer sides can be set differently, with programmable automatic left/right shoe swapping function. - Pincer mechanism equipped automatically inward pulling with synchronized

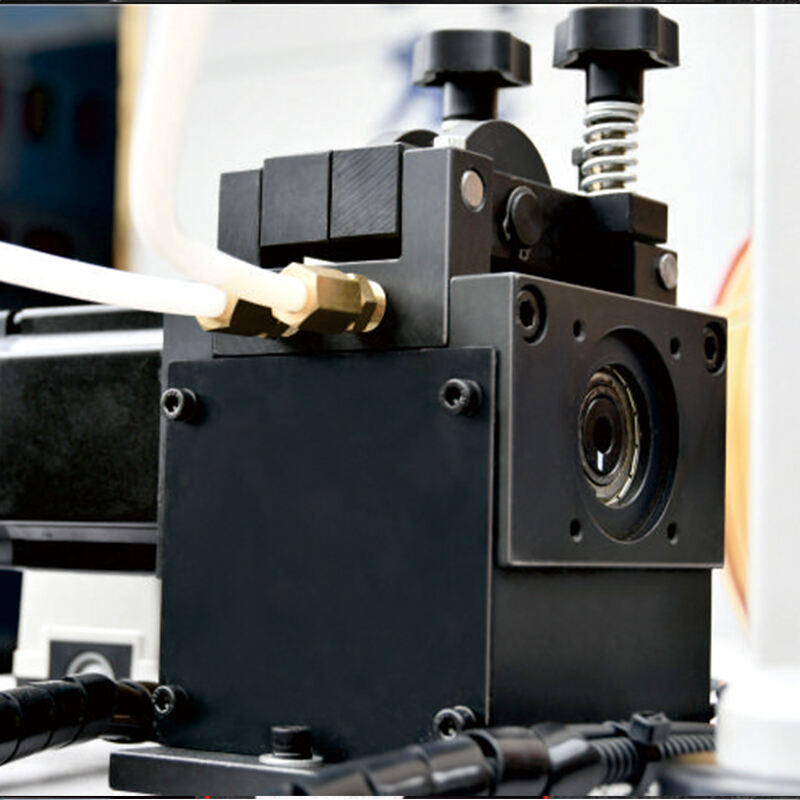

adjustment for left/right pincer's pulling pressure and individually inch up-pulling movement with automatically detection of inner waist or outer waist. - This machine equipped unique designed cementing nozzles with program able

servo-controlled visual setting cementing path to simplify the lasting procedure and reduce labor in gluing the vamp.

TECHNICAL PARAMETER

- Power :2.2Kw

- Oil pressure : 50Kg/Cm2

- Productivity : 1500pairs/8H

- Oil filling : 80 L

- N.W : 1260Kg

- Dimension : 1780(L)x1400(W)x2150(H)mm

- Packing Size : Be provided before shipment.

In the ever-evolving landscape of footwear manufacturing, precision, efficiency, and adaptability are paramount. The TH-688MAS Computer Memory Visual Locus Servo Control Side & Heel Seat Lasting Machine stands at the forefront of this evolution, offering a state-of-the-art solution that seamlessly integrates advanced technology with the intricate demands of shoe production. Designed to cater to the nuanced requirements of modern shoemaking, this machine embodies the perfect synergy of innovation and craftsmanship.

Computer Memory Visual Locus System

At the heart of the TH-688MAS lies its Computer Memory Visual Locus System, a groundbreaking feature that revolutionizes the lasting process. This system employs advanced visual recognition technology to meticulously track and memorize the contours and patterns of each shoe. By capturing and storing these visual cues, the machine ensures consistent and precise lasting operations across various shoe designs and sizes. This memory capability not only enhances the accuracy of the lasting process but also significantly reduces setup times when switching between different shoe models. Manufacturers can now achieve uniformity in production runs, ensuring that each pair of shoes meets the highest quality standards.

Servo Control Mechanism

The integration of a Servo Control Mechanism provides unparalleled precision in the movement and positioning of the machine's components. Servo motors offer rapid response times and accurate control, allowing for meticulous adjustments during the lasting process. This ensures that the upper material is perfectly aligned and stretched over the last, resulting in a flawless finish. Moreover, the servo system facilitates smooth and synchronized operations, minimizing mechanical stress and wear. This not only extends the machine's lifespan but also guarantees consistent performance over prolonged periods of use.

Side & Heel Seat Lasting Integration

The TH-688MAS is engineered to perform both side and heel seat lasting operations in a single, streamlined process. This integration eliminates the need for multiple machines or manual interventions, thereby enhancing production efficiency and reducing labor costs. By simultaneously addressing the side and heel areas, the machine ensures a cohesive and uniform fit, enhancing the structural integrity and aesthetic appeal of the final product. This holistic approach to lasting is particularly beneficial for complex shoe designs that demand meticulous attention to detail.

Programmable Parameters and Memory Storage

Understanding the diverse requirements of modern footwear, the TH-688MAS offers programmable parameters that can be tailored to specific shoe designs. Operators can adjust settings such as pressure, speed, and duration to suit various materials and styles. Furthermore, the machine boasts an extensive memory storage capacity, allowing for the retention of multiple preset configurations. This feature facilitates quick transitions between different production runs, ensuring minimal downtime and maximizing operational efficiency.

User-Friendly Interface

Equipped with an intuitive touchscreen interface, the TH-688MAS ensures ease of operation for users of varying skill levels. The interface provides real-time feedback, diagnostics, and alerts, enabling operators to monitor the machine's performance and address any issues promptly. The user-centric design minimizes the learning curve, allowing new operators to become proficient in a short span. Additionally, the interface supports multiple languages, catering to diverse manufacturing environments.

Robust Construction and Durability

Constructed with high-quality materials and components, the TH-688MAS is built to withstand the rigors of continuous industrial use. Its robust frame and precision-engineered parts ensure stability and longevity, even under demanding production schedules. The machine's design also emphasizes ease of maintenance, with accessible components and clear diagnostic indicators. This proactive approach to maintenance reduces downtime and extends the machine's operational lifespan.

Technical Specifications

>td >Control System

| Feature | Specification |

|---|---|

| Model | |

| Computer Memory Visual Locus with Servo Control | |

| Operations | Side & Heel Seat Lasting |

| Interface | Touchscreen Display |

| Memory Capacity | Multiple Preset Configurations |

| Power Supply | 380V / 50Hz |

| Dimensions | 1700mm (L) x 1300mm (W) x 1750mm (H) |

| Weight | Approximately 1200 kg |

| Production Capacity | Up to 1500 pairs per 8-hour shift |

| Air Pressure Requirement | 0.6 – 0.8 MPa |

| Noise Level | ≤70 dB |

Applications

The versatility and precision of the TH-688MAS make it an invaluable asset across various segments of the footwear industry:

Athletic and Sports Footwear

In the production of athletic shoes, where performance and comfort are paramount, the TH-688MAS ensures precise lasting that accommodates dynamic foot movements. Its ability to handle diverse materials and complex designs makes it ideal for this segment.

Formal and Dress Shoes

For formal footwear that demands impeccable aesthetics and fit, the machine's precision ensures that each pair meets the highest standards of craftsmanship. The seamless integration of side and heel seat lasts enhances the shoe's silhouette and comfort.

Casual and Fashion Footwear

In the fast-paced world of fashion, the TH-688MAS offers the flexibility to adapt to ever-changing designs and materials. Its programmable settings allow manufacturers to quickly switch between styles, ensuring timely market responses.

Safety and Work Boots

Durability and structural integrity are critical in safety footwear. The machine's robust construction and precise lasting capabilities ensure that each boot provides the necessary support and protection for demanding work environments.

Custom and Orthopedic Footwear

For specialized footwear that caters to individual needs, the TH-688MAS offers the precision and adaptability required to produce custom-fitted shoes. Its memory function ensures consistency across multiple pairs, essential for orthopedic applications.

Advantages

Enhanced Production Efficiency

By integrating multiple operations and reducing manual interventions, the TH-688MAS significantly boosts production throughput. Its rapid setup times and programmable settings minimize downtime, ensuring optimal utilization of resources.

Superior Product Quality

The machine's advanced control systems and precision engineering result in consistent and high-quality output. This consistency reduces the likelihood of defects, enhancing brand reputation and customer satisfaction.

Cost Savings

Automation of the lasting process reduces labor costs and minimizes material waste. The machine's durability and low maintenance requirements further contribute to long-term cost savings.

Flexibility and Adaptability

The TH-688MAS's ability to handle various materials, designs, and sizes makes it a versatile addition to any production line. Its programmable features allow manufacturers to swiftly adapt to market trends and customer demands.

Operator Safety and Comfort

Designed with operator well-being in mind, the machine features ergonomic controls and safety mechanisms that reduce the risk of injury and fatigue. Its quiet operation and user-friendly interface contribute to a comfortable working environment.

Maintenance and Support

To ensure the TH-688MAS operates at peak performance, regular maintenance is recommended. The machine's design facilitates easy access to key components, simplifying routine checks and servicing.

Manufacturers can also benefit from comprehensive support services, including:

-

Training Programs: Comprehensive training for operators and maintenance personnel to ensure optimal machine utilization.

-

Technical Support: Prompt assistance for troubleshooting and technical queries.

-

Spare Parts Availability: Ready access to genuine spare parts to minimize downtime.

-

Software Updates: Regular updates to enhance functionality and performance.

The TH-688MAS Computer Memory Visual Locus Servo Control Side & Heel Seat Lasting Machine represents a significant leap forward in footwear manufacturing technology. Its blend of precision, efficiency, and adaptability addresses the multifaceted challenges of modern shoemaking. By investing in this advanced machine, manufacturers position themselves at the cutting edge of the industry, ready to meet the demands of today's discerning consumers.

No posts found