COMPUTER CONTROL AUTOMATIC SERVO CEMENTING SIDE & HEEL SEAT LASTING MACHINE TH-668MA

MACHINE NAME: COMPUTER CONTROL AUTOMATIC SERVO CEMENTING SIDE & HEEL SEAT LASTING MACHINE

MODEL NO: TH-668MA

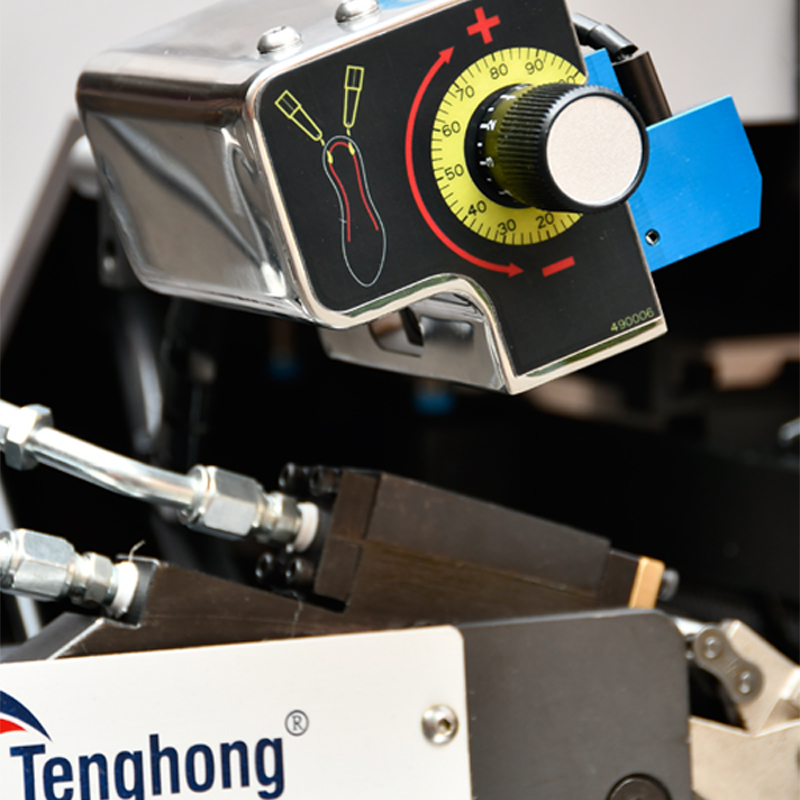

BRAND: TENGHONG

FEATURES

- Precision Glue Dispensing: Equipped with high-precision pumps and adjustable nozzles, the TH-668 MA ensures that every drop of glue is applied exactly where and how it's needed. This level of precision minimizes waste and maximizes product quality.

- Versatile Application Capabilities: Capable of handling a wide range of adhesives, including hot melt, water-based, and solvent-based glues, the TH-668 MA is suitable for diverse applications across industries. Its flexible programming allows for customization of dispensing patterns and volumes to suit specific product requirements.

- High-Speed Production: With its advanced automation system, the machine operates at impressive speeds, significantly boosting production throughput. Whether for small-scale production or large-volume manufacturing, the TH-668 MA ensures timely completion of tasks.

- Easy Integration and Operation: The machine is designed for seamless integration into existing production lines, minimizing downtime during installation. Its intuitive user interface and straightforward controls make it easy for operators to learn and use, even without extensive training.

- Durability and Maintenance: Constructed from high-quality materials, the TH-668 MA is built to last. Its robust design withstands the rigors of continuous operation, while its maintenance-friendly design simplifies routine checks and repairs.

TECHNICAL PARAMETER

- Power : 2.2K

- Packing size : 182x155x212cm

- Dimension : 170x125x194cm

- N.W : 1165Kg

- G.W : 1260Kg

The TH-668MA Computer Control Automatic Servo Cementing Side & Heel Seat Lasting Machine represents a transformative advancement in the shoe manufacturing industry. Engineered to deliver precision, speed, and reliability, this state-of-the-art machine automates the critical process of cementing the side and heel seats during shoe lasting. By integrating cutting-edge computer control and servo technology, the TH-668MA enhances production efficiency while ensuring exceptional quality and consistency. It is designed to meet the demanding needs of modern footwear manufacturers seeking to optimize their production lines, reduce labor costs, and maintain the highest standards of craftsmanship. This comprehensive description covers every aspect of the TH-668MA — from its core features and advanced technologies to its wide-ranging applications, user-friendly design, and maintenance advantages. Whether you are a large-scale manufacturer or a boutique custom shoe producer, the TH-668MA is engineered to deliver superior results with unmatched reliability.

Advanced Computer Control System

At the heart of the TH-668MA lies an intelligent computer control system that orchestrates every operation with absolute precision. The machine’s programmable logic controller (PLC) enables highly customizable settings for cementing pressure, duration, speed, and movement. This system allows operators to define and store multiple shoe models and process parameters, facilitating rapid changeovers and batch production of different shoe styles without compromising quality. The computer control system also features a real-time monitoring dashboard that displays key performance metrics and alerts operators to potential issues. This ensures not only precision but also operational transparency and ease of troubleshooting.

High-Precision Servo Motor Technology

The TH-668MA employs advanced servo motors to drive the cementing and lasting mechanisms. These motors provide superior control over movement and force application, ensuring consistent pressure is applied exactly where needed on the side and heel seat areas. The servo motors’ responsiveness enables smooth, repeatable motions that avoid damage to delicate shoe uppers and midsoles. The result is uniform adhesion quality that enhances the durability and fit of the finished shoe, reducing the need for costly reworks or material waste.

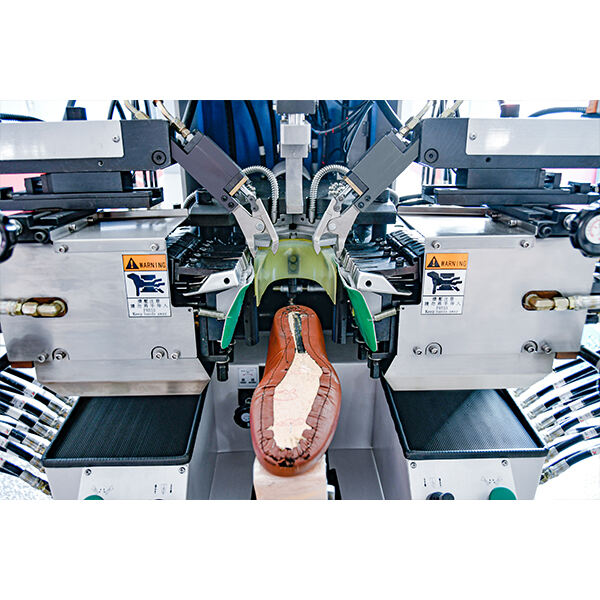

Dual Cementing Mechanisms for Side and Heel Seats

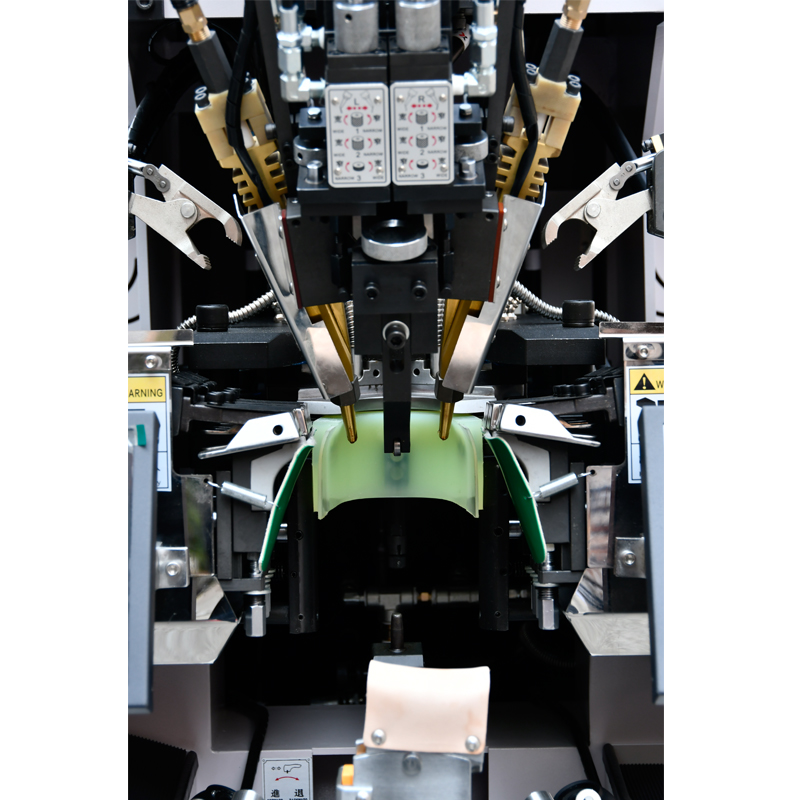

This machine specializes in cementing both the side and heel seats in a single automated process, integrating two dedicated cementing heads controlled independently yet synchronized seamlessly. This dual-head configuration boosts production throughput by allowing simultaneous or sequential cementing, depending on production demands. Each cementing head is equipped with adjustable pressure regulators and precision applicators, ensuring optimal glue distribution tailored to different shoe sizes, shapes, and materials.

Servo-Driven Lasting Arms with Multi-Axis Movement

The lasting arms, powered by servo drives, feature multi-axis articulation, enabling them to maneuver complex shoe geometries with ease. This flexibility allows the TH-668MA to accommodate a wide range of shoe designs, including athletic, casual, formal, and specialized footwear. The arms gently stretch and mold the shoe upper over the lasting form while simultaneously applying cement, ensuring a perfect fit and flawless adhesion without causing wrinkles or distortion.

Intelligent Glue Dispensing System

Integrated with the latest glue application technology, the TH-668MA includes an intelligent glue dispensing system designed for precise, controlled cement flow. This system supports various adhesive types commonly used in shoe manufacturing, such as polyurethane-based cement and EVA adhesives. The glue pump features adjustable flow rates and intermittent dispensing modes that minimize waste and prevent glue overflow, maintaining a clean working environment and reducing production downtime for cleanup.

Modular Work Platform

Designed with versatility in mind, the TH-668MA includes a modular work platform that can be quickly adjusted or expanded to accommodate shoes of varying sizes and styles. This adaptability ensures the machine can easily handle different production batches without lengthy reconfiguration, streamlining operations, and maximizing uptime. The platform is ergonomically designed to allow easy loading and unloading of shoe lasts, further enhancing workflow efficiency.

User-Friendly Interface with Touchscreen Controls

The operator interface features a large color touchscreen display with intuitive menus and real-time process visualization. Operators can easily select shoe models, adjust parameters, and monitor the status of each cementing cycle with minimal training. Multi-language support and built-in help guides make the interface accessible for diverse workforces and facilitate rapid onboarding of new personnel.

Robust Construction for Industrial Use

Constructed from high-grade steel and corrosion-resistant materials, the TH-668MA is built to withstand the demanding conditions of a high-volume shoe production environment. Its rugged frame ensures stability and minimizes vibration during operation, which contributes to consistent cementing quality. The machine is also designed with safety in mind, featuring emergency stop buttons, safety guards, and compliance with international industrial safety standards.

Automated Quality Control and Error Detection

The machine incorporates sensors and cameras to continuously inspect the cementing process. These quality control systems detect glue application anomalies, missing adhesion spots, or mechanical misalignments. In case of deviations, the system can halt the production cycle, alert operators, or automatically adjust parameters to correct issues in real time. This reduces the rate of defective products and helps maintain stringent quality standards without the need for extensive manual inspection.

Energy-Efficient Operation

In line with modern manufacturing sustainability goals, the TH-668MA uses energy-efficient servo motors and optimized pneumatic systems that reduce power consumption without compromising performance. The machine’s software includes power-saving modes during idle periods, further lowering operating costs and environmental impact.

Technical Specifications

| Specification | Details |

|---|---|

| Machine Dimensions | 2800 mm (L) x 1500 mm (W) x 1800 mm (H) |

| Weight | Approx. 1200 kg |

| Power Supply | 380V/50Hz, 3-phase |

| Air Pressure Requirement | 0.6–0.8 MPa |

| Cementing Pressure Range | 5–60 N/cm² |

| Servo Motor Power | 1.5 kW (x2) |

| Operating Speed | Up to 120 pairs/hour |

| Work Platform Size | Adjustable 100–320 mm shoe size range |

| Glue Types Supported | Polyurethane, EVA, Hot Melt |

| Control System | PLC with touchscreen HMI |

| Safety Features | Emergency stops, safety guards |

| Noise Level | ≤70 dB |

| Warranty | 12 months or 2000 operating hours |

Applications

Footwear Manufacturing

The TH-668MA is ideally suited for all categories of shoe production, including:

-

Athletic Shoes: Ensures durable and flexible adhesion for running shoes, sneakers, and sports footwear.

-

Casual and Fashion Shoes: Maintains aesthetic integrity while providing a robust bond for uppers and soles.

-

Safety and Work Boots: Offers reliable cementing that withstands harsh working conditions and extended wear.

-

Orthopedic and Medical Shoes: Provides precise application suited for sensitive designs requiring exact glue placement.

By automating the cementing of side and heel seats, the machine reduces the manual labor traditionally involved in this labor-intensive task, speeding up production and improving consistency.

Shoe Repair and Aftermarket Services

The machine can also be used by shoe repair shops and factories specializing in refurbishment to apply cement precisely during heel replacement or sole repairs, ensuring a factory-quality finish.

Prototype and Small-Batch Production

Thanks to its programmable controls and adjustable platform, the TH-668MA accommodates small production runs and prototypes, allowing manufacturers to quickly test new shoe designs with minimal setup time.

Benefits of Using the TH-668MA

Enhanced Production Efficiency

By automating the cementing and lasting of side and heel seats, the TH-668MA dramatically reduces cycle times compared to manual or semi-automated processes. With the ability to process up to 120 pairs per hour, manufacturers can significantly increase throughput without sacrificing quality.

Superior Product Quality

The machine’s precision servo control and intelligent glue dispensing ensure consistent and uniform cement application, resulting in durable adhesion and a polished final product. This consistency reduces returns and complaints caused by adhesive failure.

Reduced Labor Costs

Automating the most labor-intensive parts of the shoe lasting process frees skilled workers to focus on other value-added tasks, lowering overall labor costs and improving workforce allocation.

Increased Flexibility

Whether producing different shoe models or adjusting for new glue formulations, the TH-668MA’s programmable control system and modular design allow quick adaptation without lengthy downtime or complex retooling.

Improved Workplace Safety

The machine’s safety features and ergonomic design reduce operator strain and the risk of accidents associated with manual cementing and lasting tasks.

Sustainable Manufacturing

Energy-efficient components and minimal glue waste contribute to environmentally responsible production, helping manufacturers meet sustainability goals and reduce their carbon footprint.

Lower Maintenance Requirements

The machine’s intelligent self-diagnostic system monitors mechanical health and alerts operators to required maintenance before failures occur. This predictive maintenance reduces unexpected downtime and extends machine lifespan.

Installation and Training

The TH-668MA is designed for straightforward integration into existing production lines. Our expert technical team provides on-site installation and commissioning services, ensuring the machine operates optimally from day one. Comprehensive operator training programs cover machine operation, safety protocols, routine maintenance, and troubleshooting. Training is tailored to the skill levels of your workforce to maximize user confidence and operational efficiency.

Customer Support and Service

Purchasing the TH-668MA means gaining access to a global network of technical support and service. Our commitment to customer satisfaction includes:

-

24/7 Technical Support Hotline: Prompt assistance whenever you need it.

-

Spare Parts Availability: Genuine parts stocked for fast replacement.

-

Preventive Maintenance Contracts: Scheduled visits to keep your machine in peak condition.

-

Software Updates: Regular enhancements to control software for new features and improved performance.

Case Studies and Testimonials

Company A: High-Volume Sports Footwear Manufacturer

By integrating the TH-668MA, Company A increased its production output by 35% while reducing glue waste by 20%. Operators reported greater ease of use and less fatigue, improving overall job satisfaction.

Company B: Boutique Custom Shoe Maker

Thanks to the machine’s flexible programming, Company B quickly switched between various shoe designs without delays, allowing them to meet diverse customer demands efficiently and maintain high-quality standards.

The TH-668MA Computer Control Automatic Servo Cementing Side & Heel Seat Lasting Machine embodies the future of shoe manufacturing technology. Its blend of intelligent computer control, servo precision, and robust design provides manufacturers with a powerful tool to enhance production speed, reduce costs, and ensure product excellence. Whether you are scaling your production capacity or refining your craftsmanship, the TH-668MA offers the versatility, reliability, and efficiency required to stay competitive in today’s dynamic footwear industry.

No posts found