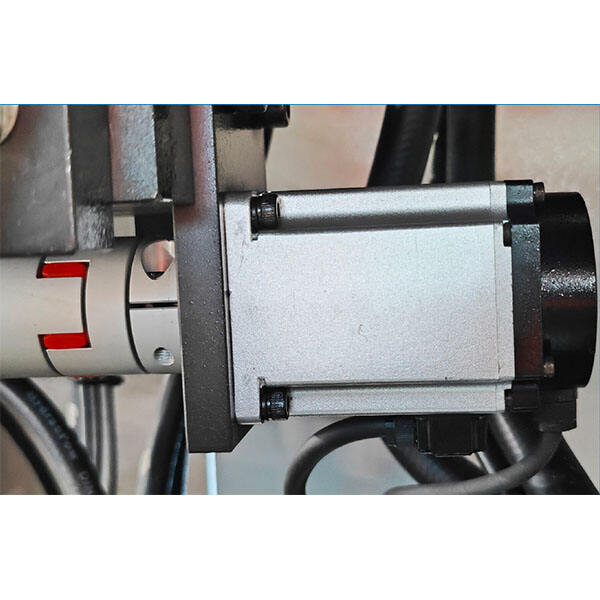

AUTOMATIC CEMENTING SIDE & HEEL SEAT LASTING MACHINE TH-658MA

MACHINE NAME: AUTOMATIC CEMENTING SIDE & HEEL SEAT LASTING MACHINE

MODEL NO: TH-658MA

BRAND: TENGHONG

FEATURES

- The machine uses oil pressure for collaborative operation.

- Using PLC controller and graphic display touch screen, the operation is the most stable and convenient.

- The setting of lasting parameters (travel and time) is input in numerical mode and a key switch is set to freely switch between automatic and semi-automatic operation.

- Self debugging function, saving troubleshooting time.

- The middle lasting machine is equipped with five groups of side pressing and finger pressing structures, and is specially designed with a heel lasting wiper mechanism to form an overlapping action of the lasting position and reduce the bad lasting at the joint point.

- The finger pressure structure has the function of automatic balance and can set two pressure actions.

- The inner and outer waist are equipped with a claw, which can be used to pull the lining side and the back part of the upper to achieve a perfect lasting effect.

- This machine can choose to use the operation mode of back lasting, middle lasting and side & heel lasting.

- The carefully designed lasting action and the adjustable time control of each part make the lasting speed of this machine faster, and the operation is simple and easy to adjust, which greatly improves the production capacity and efficiency.

- The middle lasting manual adjustment of height, it is simple and fast to operate.

- When the pincers move, they can be adjusted electrically and can memorize the position.

TECHNICAL PARAMETER

- Capacity : 1500 pairs/H

- Power : 3HP(2.2Kw)

- Net weight : 1165kg

- Heating Power : 5kw

- Oil Filling : 70 liters

- Gross weight : Be provided before shipment.

- Dimension : 1700(L)x1250(W)x1940mm(H)

- Packing size : 1820(L)x1550(W)x2110mm(H)

The TH-658MA Automatic Cementing Side & Heel Seat Lasting Machine represents the pinnacle of modern footwear manufacturing technology, engineered to revolutionize the way shoes are assembled by automating the crucial side and heel lasting processes with cement application. Designed for manufacturers striving to maximize efficiency, ensure consistent product quality, and reduce labor costs, the TH-658MA delivers high-speed, precise, and reliable cementing lasting performance in a fully automated environment. With footwear production evolving rapidly, manufacturers demand machinery that not only keeps pace but drives innovation. The TH-658MA integrates state-of-the-art automation, advanced control systems, and intelligent design to provide a seamless cementing lasting solution. It is tailored to meet the rigorous demands of both high-volume factory floors and precision-driven custom orders, making it an indispensable asset across a variety of shoe manufacturing sectors.

Fully Automated Cementing Lasting Process

The TH-658MA is a fully automated machine that expertly handles both side lasting and heel seat lasting while simultaneously applying cement. This integration streamlines production by eliminating manual steps that were traditionally labor-intensive, error-prone, and time-consuming.

-

Precision Cement Application: The system uses advanced cementing heads that apply adhesive with exact control over quantity, placement, and pressure to ensure perfect bonding without waste or mess.

-

Automated Lasting Control: The machine’s robotic arms and precision fixtures hold the shoe components securely and perform lasting operations with uniform force, resulting in superior and consistent shoe shape and fit.

-

High Repeatability: Each shoe is processed under identical parameters, drastically reducing variability and improving overall product quality.

Superior Engineering for Side & Heel Seat Lasting

The side and heel seat lasting are critical steps in shoe construction that determine the final shape, durability, and comfort of the footwear. The TH-658MA is expertly designed to address these challenges with:

-

Ergonomic Lasting Mechanism: Optimized for applying precise tension and pressure around the shoe upper, especially at the sidewalls and heel seat area, ensuring a smooth, wrinkle-free finish.

-

Multi-Directional Lasting Arms: These arms are capable of fine-tuned movements in multiple axes to adapt to diverse shoe styles and sizes without compromising structural integrity.

-

Adjustable Fixtures: Easily configurable to different shoe lasts, enabling quick changeover and adaptability across production runs.

Intelligent Control System with User-Friendly Interface

Modern manufacturing demands machinery that is not only powerful but also easy to operate and integrate. The TH-658MA features a sophisticated but intuitive control system that simplifies operation and maintenance.

-

Touchscreen HMI: The machine is equipped with a high-resolution color touchscreen display, providing operators with clear, real-time data, process controls, and diagnostic feedback.

-

Programmable Settings: Operators can store and recall lasting parameters for various shoe models, enabling rapid setup and minimizing downtime.

-

Remote Monitoring & Diagnostics: The machine supports network connectivity for remote troubleshooting, firmware updates, and predictive maintenance alerts, ensuring minimal operational interruptions.

High Throughput & Operational Efficiency

With cycle times optimized through advanced robotics and process engineering, the TH-658MA offers some of the fastest lasting speeds in its class without sacrificing quality.

-

Rapid Cement Drying Coordination: The cementing system synchronizes with lasting operations to optimize drying time and reduce bottlenecks.

-

Minimal Manual Intervention: Once started, the machine requires minimal human involvement, freeing labor for other production tasks and increasing overall plant productivity.

-

Energy Efficient Components: By incorporating energy-saving motors and control algorithms, the machine reduces electricity consumption while maintaining peak performance.

Robust Build Quality & Maintenance Simplicity

Designed for 24/7 industrial use, the TH-658MA is constructed with durable materials and components to withstand heavy workloads and harsh factory environments.

-

Heavy-Duty Frame: The solid steel framework ensures stability and vibration resistance for consistent operation.

-

Easy Access Panels: Maintenance points such as cement reservoirs, lubrication points, and sensor calibrations are easily accessible for routine service.

-

Smart Fault Detection: Integrated sensors monitor machine status and alert operators early to potential issues, reducing downtime through preventive maintenance.

Applications Across Industries

The TH-658MA Automatic Cementing Side & Heel Seat Lasting Machine is ideally suited to a broad range of industries where efficient and high-quality footwear production is essential.

Footwear Manufacturing

In shoe factories, the TH-658MA dramatically improves throughput and quality consistency across various footwear types — from athletic shoes to fashion footwear to safety boots. It enables manufacturers to meet high consumer demand while maintaining strict quality standards.

Sportswear & Athletic Shoes

Sports shoes require precise construction to ensure comfort, durability, and performance. The TH-658MA’s exact cementing and lasting capabilities help produce shoes that meet the rigorous demands of athletes, supporting superior fit and structural integrity.

Leather Goods and Luxury Shoes

Luxury footwear production demands impeccable finishing and craftsmanship. The machine’s precise pressure control and adaptable lasting mechanism preserve leather quality and prevent material damage, ensuring premium aesthetics and comfort.

Orthopedic & Medical Footwear

Orthopedic shoes require customized lasts to support proper foot biomechanics. The TH-658MA’s programmable settings allow production of personalized footwear designs that meet specific medical requirements with consistent quality.

Industrial & Safety Footwear

Heavy-duty and safety shoes need strong adhesive bonds and reliable lasting to ensure protection and durability. The TH-658MA offers robust cementing and lasting control for these high-demand applications, improving the safety and lifespan of the footwear.

Advantages Over Traditional Methods

The TH-658MA sets itself apart from manual or semi-automated lasting processes with several key advantages:

-

Reduced Labor Costs: Automation minimizes the need for skilled manual labor, reducing personnel expenses and human error.

-

Enhanced Product Quality: Uniform lasting pressure and cement application guarantee consistent shoe shapes and bonding strength, reducing returns and defects.

-

Faster Production Times: Optimized cycle times increase output and enable just-in-time manufacturing.

-

Improved Workplace Safety: Automated operation reduces operator exposure to repetitive strain injuries and chemical hazards from adhesives.

-

Sustainability: Efficient cement usage and energy-saving design contribute to greener manufacturing operations.

Detailed Operational Workflow

-

Shoe Preparation: Shoe components are loaded onto the machine’s fixtures either manually or via conveyor systems.

-

Lasting Fixture Positioning: The lasting platform adjusts automatically to fit the shoe size and style.

-

Cement Application: The adhesive applicator precisely sprays cement on the side and heel areas based on programmed patterns.

-

Side Lasting Process: Robotic arms pull and stretch the upper around the shoe last’s sides, ensuring tight and wrinkle-free lasting.

-

Heel Seat Lasting: Specialized clamps and presses form the heel seat area with exact pressure to optimize comfort and durability.

-

Drying & Inspection: The machine includes a brief pause allowing cement drying before ejection or transfer for further assembly.

-

Cycle Repeat: The machine resets and is ready for the next shoe component with minimal delay.

Customization & Integration Options

Manufacturers can customize the TH-658MA to fit specific production line requirements, including:

-

Integration with upstream and downstream conveyor or robotic systems for fully automated production lines.

-

Customized cement application nozzles for different adhesive types or viscosities.

-

Expanded size ranges and tooling for specialty footwear.

-

Software upgrades for enhanced data analytics and integration with MES (Manufacturing Execution Systems).

Environmental and Safety Considerations

In today’s manufacturing environment, environmental compliance and worker safety are paramount. The TH-658MA addresses these with:

-

Low-VOC Cement Application: Compatible with modern, environmentally friendly adhesives that reduce volatile organic compound emissions.

-

Efficient Material Usage: Precise cement application reduces waste and excess adhesive runoff.

-

Operator Safety Features: Safety interlocks, emergency stops, and protective guarding prevent accidents during operation.

-

Energy Management: The machine’s control system optimizes motor and pneumatic usage, reducing overall energy demand.

Customer Support & Training

Purchasing the TH-658MA comes with comprehensive customer service offerings:

-

Installation & Commissioning: Expert technicians ensure smooth setup and calibration at the customer site.

-

Operator Training: Hands-on training for operators and maintenance staff to maximize machine utilization and longevity.

-

Technical Support: Ongoing remote and on-site support to troubleshoot issues and perform upgrades.

-

Spare Parts Availability: Ready supply of essential components for fast maintenance.

The TH-658MA Automatic Cementing Side & Heel Seat Lasting Machine is a transformative solution for modern footwear manufacturers who seek to enhance production efficiency, improve product quality, and reduce operational costs. By integrating advanced automation, precise cement application, and intelligent control systems, the TH-658MA ensures every shoe produced meets the highest standards of craftsmanship and durability. This machine stands as a testament to engineering excellence, designed to future-proof your manufacturing process while contributing to sustainable and safe working conditions. Whether your operation focuses on mass production or specialized footwear, the TH-658MA is engineered to deliver outstanding results, making it a vital investment in your production technology arsenal.

No posts found