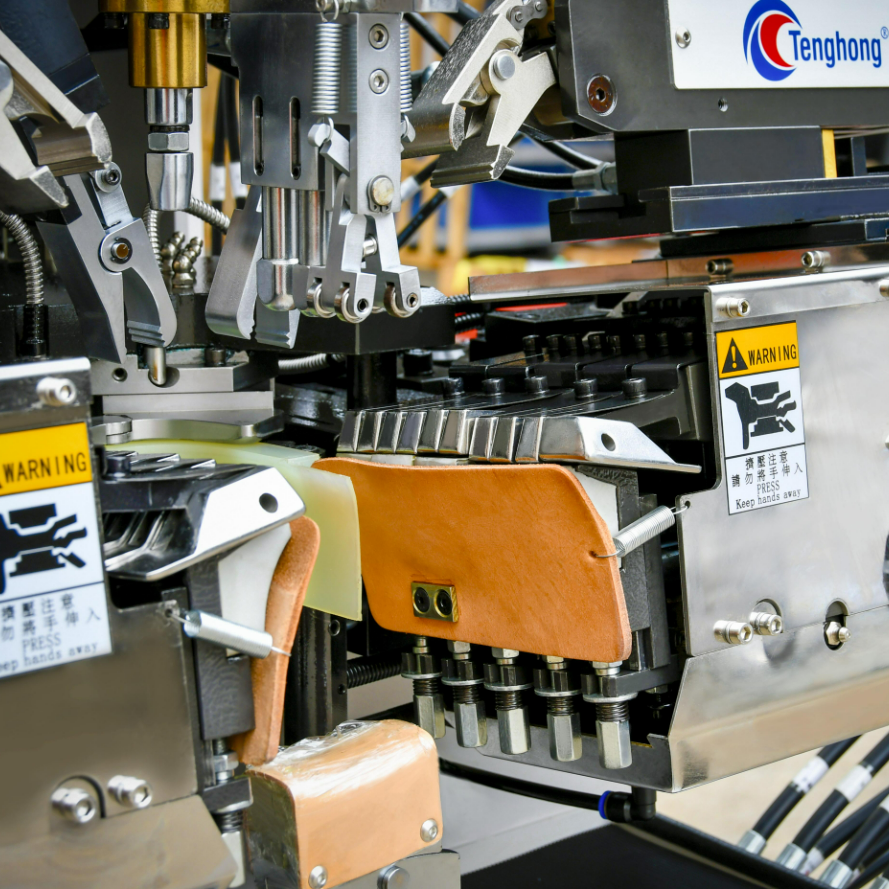

AUTOMATIC SIDE & HEEL SEAT LASTING MACHINE WITHOUT CEMENTING TH-658B

MACHINE NAME: AUTOMATIC SIDE & HEEL SEAT LASTING MACHINE WITHOUT CEMENTING

MODEL NO: TH-658B

BRAND: TENGHONG

FEATURES

- Introducing the TH-658B Non-Adhesive Rear Help Machine, a cutting-edge industrial solution designed to streamline the post-processing of non-adhesive materials with unparalleled efficiency and precision. This innovative machine is the ultimate tool for manufacturers seeking to optimize their production lines, enhance product quality, and minimize labor costs.

- Specialized for Non-Adhesive Materials: The TH-658B is specifically engineered to handle the unique challenges posed by non-adhesive materials such as specialized plastics, rubbers, and composites. Its proprietary processing mechanism ensures these materials are processed without adhesion, deformation, or damage, preserving their integrity and performance.

- High-Efficiency Automation: Equipped with an advanced automation system, the TH-658B operates seamlessly from start to finish, requiring minimal human intervention. Its precise robotic arms and sensors guarantee accuracy in every step, driving up production rates and enhancing overall efficiency.

- Versatile and Adaptable: The machine boasts a flexible work platform and a range of processing modes, enabling it to tackle diverse materials of varying sizes, shapes, and compositions. Whether for small-batch prototyping or large-scale production, the TH-658B is always ready to deliver.

- Eco-Friendly and Energy-Efficient: While maximizing performance, the TH-658B also prioritizes environmental sustainability. It employs low-energy motors and optimized workflows to minimize energy consumption and carbon emissions, aligning with modern green manufacturing principles.

- Intelligent Maintenance System: Equipped with smart fault diagnosis and maintenance alerts, the machine continuously monitors its own health, identifying potential issues before they become problems. This predictive maintenance capability ensures continuous operation, reduced downtime, and extended machine lifespan.

APPLICATIONS:

The TH-658B Non-Adhesive Rear Help Machine finds its place in various industries, including automotive manufacturing, aerospace, electronics, medical devices, and packaging materials. It empowers these sectors to achieve higher levels of automation and intelligence in their production processes, ultimately driving innovation and growth.

In conclusion, the TH-658B Non-Adhesive Rear Help Machine stands as a testament to advanced engineering and innovation. With its superior performance, automation capabilities, versatility, eco-friendliness, and intelligent maintenance system, it is the ultimate solution for modern manufacturers working with non-adhesive materials.

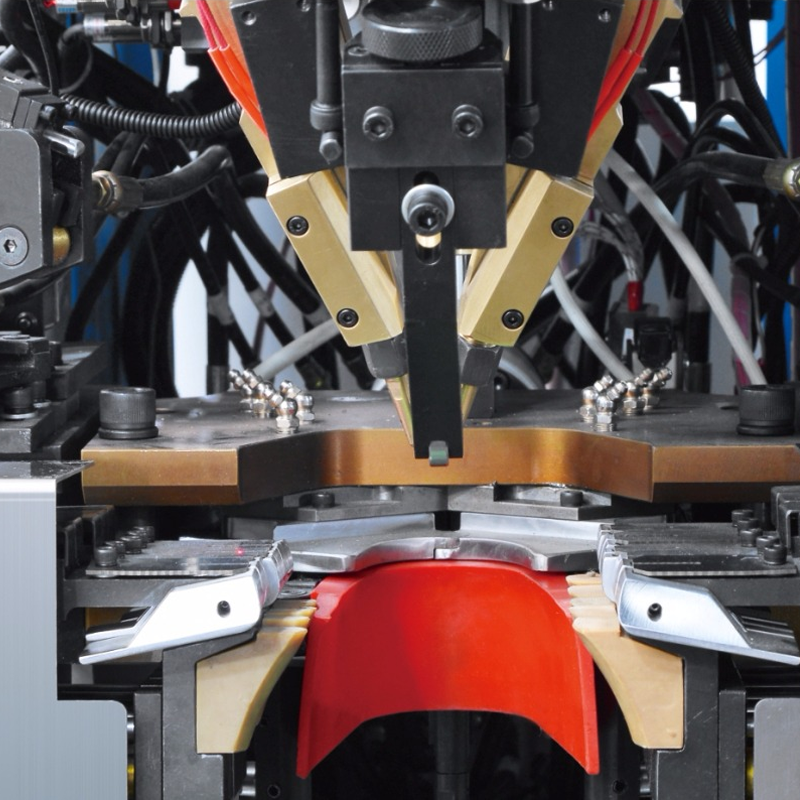

The TH-658B Automatic Side & Heel Seat Lasting Machine, without Cementing, represents a revolutionary advancement in footwear manufacturing technology. Engineered for high efficiency, precision, and eco-friendliness, this cutting-edge machine is designed to transform traditional shoe lasting methods by automating the process of side and heel seat lasting without the need for cement adhesives. By eliminating cementing, the TH-658B not only enhances production speed and quality but also supports manufacturers’ sustainability goals and cost-effectiveness. Whether you are a footwear manufacturer seeking to upgrade your production line or a large-scale factory aiming for improved product consistency and reduced labor, the TH-658B is a game-changing solution tailored to meet the demands of modern shoe making.

Specialized Cement-Free Lasting Technology

One of the most significant innovations embodied by the TH-658B is its specialized cement-free lasting technology. Traditional lasting machines rely heavily on adhesives (cement) to attach the shoe upper to the sole, a process that can be messy, time-consuming, and environmentally hazardous. The TH-658B, however, is engineered to securely and efficiently perform side and heel seat lasting without the use of cement, reducing the use of chemicals and eliminating the drying time required for adhesives. This technology utilizes advanced mechanical pressure and precision tooling to firmly bond the shoe components, ensuring that the shoe’s structural integrity and aesthetic finish are preserved without the risks of glue seepage, uneven bonding, or chemical odors. This approach leads to cleaner production environments and safer workplaces, while also delivering durable, high-quality footwear.

High-Efficiency Automation System

The TH-658B integrates a fully automated system designed for seamless operation from start to finish. With advanced robotics, sensor arrays, and computer-controlled mechanics, the machine automates the lasting process with unparalleled precision.

-

Robotic Arms and Grippers: Equipped with precise robotic arms, the machine can handle shoe uppers and soles delicately and accurately, positioning them perfectly for lasting.

-

Sensor-Driven Alignment: Sophisticated sensors detect the shoe’s exact dimensions and positioning, allowing the machine to adjust pressure and alignment dynamically, ensuring flawless results regardless of shoe style or size.

-

Minimal Human Intervention: Once set up, the TH-658B requires minimal operator involvement, freeing skilled workers to focus on quality control and other high-value tasks while reducing human error and labor costs.

This automation capability dramatically increases production throughput and ensures a consistent finish across every pair of shoes.

Versatility and Adaptability for Diverse Footwear

The TH-658B’s flexible work platform and customizable settings allow it to accommodate a wide array of shoe designs, materials, and sizes. This makes it highly suitable for manufacturers who produce a diverse range of footwear, including:

-

Athletic and sports shoes

-

Casual and everyday wear

-

Formal and leather shoes

-

Specialized footwear like orthopedic or safety shoes

With adjustable tooling and processing modes, the machine can easily switch between different shoe models, supporting both small-batch prototyping and large-scale manufacturing runs. This adaptability ensures that manufacturers remain competitive by responding quickly to market trends and customer demands.

Eco-Friendly and Energy-Efficient Design

Sustainability is a growing priority in manufacturing industries worldwide, and the TH-658B is developed with this imperative in mind. The machine features:

-

Low-Energy Motors: Designed to consume less power without compromising performance.

-

Optimized Mechanical Workflow: The machine’s internal processes are streamlined to reduce waste and minimize unnecessary energy use.

-

No Adhesive Emissions: By eliminating cementing, the TH-658B prevents harmful volatile organic compounds (VOCs) from entering the factory environment, improving air quality and worker safety.

By combining high performance with green manufacturing principles, the TH-658B helps companies reduce their carbon footprint and comply with increasingly stringent environmental regulations.

Intelligent Maintenance and Fault Diagnosis System

To ensure maximum uptime and reliable operation, the TH-658B is equipped with a state-of-the-art intelligent maintenance system that monitors the machine’s health in real-time. Features include:

-

Smart Fault Detection: The system continuously scans for irregularities or potential faults in mechanical, electrical, or control components.

-

Maintenance Alerts: Operators receive timely notifications for routine maintenance or parts replacement, preventing unexpected breakdowns.

-

Predictive Analytics: Advanced algorithms analyze usage patterns to predict when components will require servicing, optimizing maintenance schedules.

This proactive maintenance approach reduces downtime, extends the machine’s service life, and lowers overall operational costs.

Detailed Technical Overview

To fully appreciate the capabilities of the TH-658B, it’s essential to delve into the technical aspects that make this machine stand out.

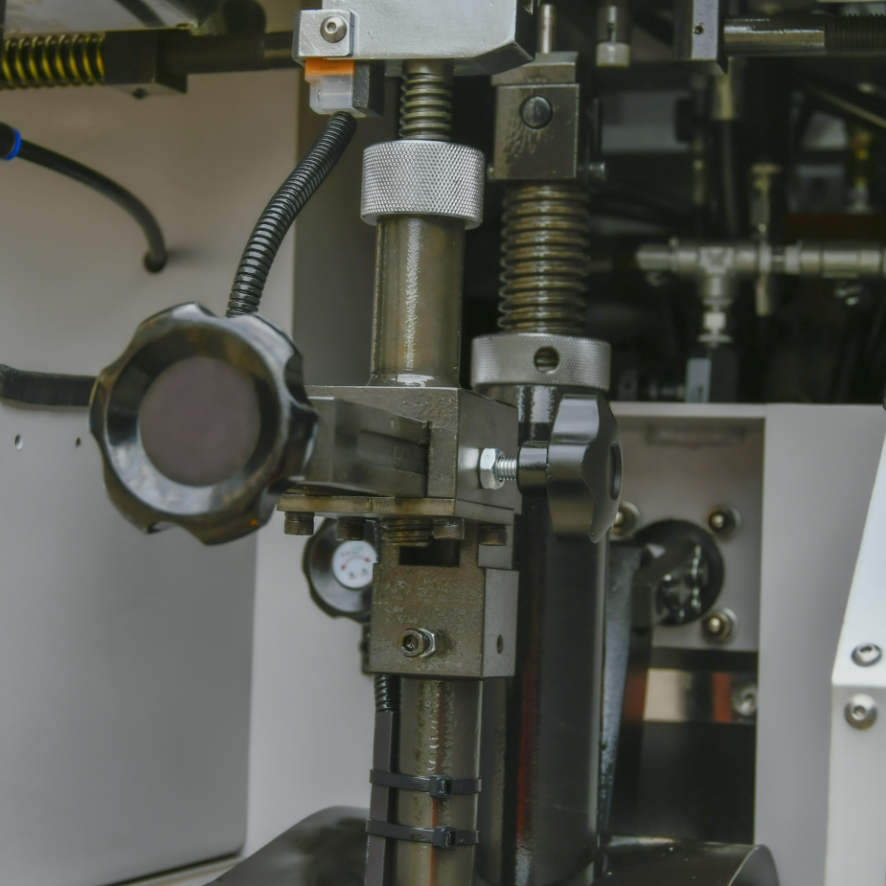

Precision Engineering and Build Quality

Crafted from high-grade industrial materials and components, the TH-658B is built to withstand the rigorous demands of continuous production in a busy factory environment. The machine’s frame is reinforced for stability, and critical parts are machined to tight tolerances, ensuring consistent performance and long-term durability.

Control System and Interface

The machine uses an advanced programmable logic controller (PLC) system that governs the entire lasting process. The user-friendly touchscreen interface allows operators to:

-

Set lasting parameters for different shoe models

-

Monitor production cycles in real-time

-

Access diagnostic data and error logs

-

Adjust pressure, timing, and alignment settings with ease

Tooling and Fixture System

Specialized tooling holds and shapes the shoe upper and sole during the lasting operation. The fixtures are adjustable to accommodate various shoe sizes and materials, and can be swapped out quickly to switch production lines, maximizing operational flexibility.

Safety Features

Operator safety is paramount. The TH-658B incorporates multiple safety mechanisms, including:

-

Emergency stop buttons are strategically placed around the machine

-

Safety light curtains and guards to prevent accidental access during operation

-

Automatic shutdown if sensors detect abnormal conditions

Applications and Industry Impact

The TH-658B Automatic Side & Heel Seat Lasting Machine without Cementing is not limited to a single sector but finds wide applications across the footwear manufacturing industry:

-

Footwear Factories: Ideal for large-scale production of various shoe types, improving speed and quality.

-

OEM and ODM Manufacturers: Support flexible production runs tailored to client specifications.

-

Specialized Footwear Production: Orthopedic, sports, and safety shoe manufacturers benefit from precise, cement-free lasting.

-

Eco-Conscious Brands: Companies prioritizing green manufacturing gain a competitive edge with adhesive-free processing.

Benefits to Manufacturers

Implementing the TH-658B in your production line offers numerous advantages:

Increased Production Efficiency

By automating a traditionally labor-intensive process, manufacturers can increase throughput significantly without compromising quality.

Reduced Labor Costs

Minimal operator involvement results in fewer labor hours per shoe, thereby lowering production costs.

Improved Product Quality and Consistency

Precision controls ensure each shoe is lasted uniformly, reducing defects and returns.

Cleaner and Safer Work Environment

Eliminating adhesive use removes associated hazards and messy cleanup.

Environmental Compliance

Supports manufacturers in meeting sustainability goals and regulations.

How the TH-658B Fits Into Modern Smart Manufacturing

The footwear industry is rapidly evolving with the adoption of Industry 4.0 principles, automation, data integration, and smart manufacturing. The TH-658B is designed to integrate seamlessly with these trends:

-

Data Connectivity: The machine’s control system can be connected to factory-wide networks for real-time monitoring and analytics.

-

Scalability: Suitable for integration into fully automated production lines alongside other smart equipment.

-

Operator Training and Ease of Use: Its intuitive interface shortens the learning curve and supports workforce upskilling.

Installation, Training, and Support

Purchasing the TH-658B comes with comprehensive support services:

-

On-Site Installation and Commissioning: Expert technicians ensure smooth setup and calibration.

-

Operator Training: Tailored training sessions help your staff master machine operation and maintenance.

-

After-Sales Support: Reliable technical support and spare parts availability to keep your machine running optimally.

Customer Success Stories

Leading footwear manufacturers across the globe have adopted the TH-658B to great success. They report:

-

Significant boosts in production capacity

-

Substantial reductions in waste and production defects

-

Enhanced workplace safety and cleaner shop floors

-

Positive environmental impact through cement-free production

Future Developments and Upgrades

The TH-658B platform is continuously evolving, with upcoming features such as:

-

Enhanced AI-powered quality inspection modules

-

Integration with robotic packing systems

-

Cloud-based production analytics dashboards

This ensures your investment remains cutting-edge and future-proof.

The TH-658B Automatic Side & Heel Seat Lasting Machine without Cementing is more than just a piece of machinery—it’s a strategic enabler for footwear manufacturers ready to step into the future of efficient, sustainable, and high-quality shoe production. By combining innovative cement-free technology, automation precision, adaptability, eco-conscious design, and intelligent maintenance, the TH-658B delivers unmatched value and performance. For manufacturers committed to excellence and environmental responsibility, the TH-658B is the ultimate solution to elevate your production capabilities and competitive advantage.

No posts found