HORIZONTAL BILATERAL DYEING MACHINE TH-630

MACHINE NAME: HORIZONTAL BILATERAL DYEING MACHINE

MODEL NO: TH-630

BRAND: TENGHONG

FEATURES

- This product is suitable for oil edge coloring of leather products, shoulders straps, belts, edge strips, and other strips shaped products. It adopts dual wheel synchronous coloring, and the coloring wheel adopts an arc-shaped toothed structure, ensuring uniform and fast coloring.

TECHNICAL PARAMETER

- Model : TH-630

- Width Adjustment Range : 5-40mm

- Power : 150w

- Voltage : 220V

- Dimension : 500x460x400mm

- Weight : 40kg

The TH-630 Horizontal Bilateral Dyeing Machine is a cutting-edge solution tailored for precision oil edge coloring in the leatherworking and accessories industries. Designed for professional artisans, manufacturers, and leather goods workshops, the TH-630 offers advanced dual-wheel synchronous coloring capabilities. Engineered to deliver consistent, efficient, and aesthetically superior edge finishes, this machine redefines edge dyeing standards across a wide spectrum of strip-shaped leather products. With its arc-shaped toothed coloring wheels and bilateral configuration, the TH-630 makes edge coloring faster, smoother, and more uniform than ever before. Ideal for shoulder straps, belts, leather edge strips, and similar components, the machine minimizes manual labor while maximizing productivity and finish quality. Whether used for small-batch customization or medium-scale production, it represents an exceptional investment in craftsmanship and automation.

Purpose and Application

The TH-630 is purpose-built for applying oil-based edge dye to leather and synthetic leather strips of various sizes and thicknesses. This includes, but is not limited to:

-

Leather shoulder straps

-

Fashion belts

-

Edge strips and trim

-

Bag and luggage handles

-

Footwear components

-

Watch bands

-

Upholstery edging

-

Industrial strap segments

It is especially suitable for straight or slightly contoured strip-shaped products requiring even bilateral edge finishing. By using dual-wheel simultaneous dyeing, it not only saves time but also ensures perfect color symmetry across both edges. The machine is a valuable asset for businesses producing fashion accessories, leather garments, saddlery, automotive interiors, and premium lifestyle goods. It allows artisans and industrial users alike to maintain a consistent quality across various product batches, eliminating uneven hand-dyeing flaws and inefficiencies.

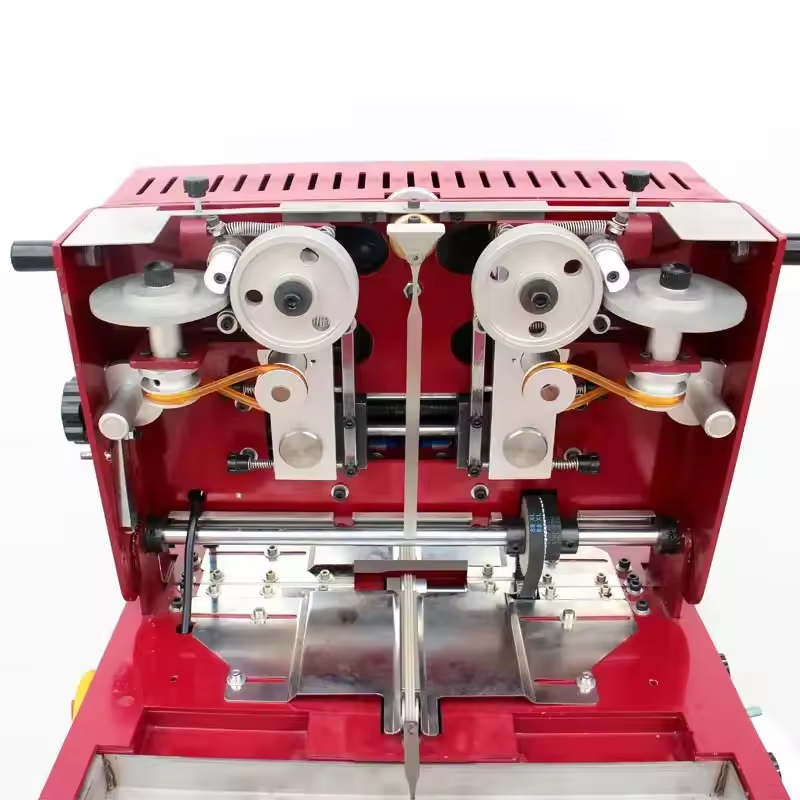

Design and Construction

The TH-630 is designed with durability, ergonomics, and high performance in mind. Its robust steel chassis ensures a vibration-free operation and long-term reliability, even under continuous use. With a compact yet solid footprint, the machine integrates seamlessly into any production line or workshop setting. The bilateral horizontal structure places the dual dyeing wheels on either side of the strip material, allowing synchronized operation. This horizontal layout is ideal for strips that require both sides dyed in a single pass, significantly reducing operation time and material handling. The arc-shaped, d-toothed dyeing wheels are engineered for high efficiency and precise color application. The arc design accommodates a wide range of leather edge shapes, ensuring full dye penetration even along slightly contoured surfaces. The toothed structure enhances grip and even distribution of dye, preventing streaks, blotches, or over-saturation . All components, from the motor to the wheel assembly, are chosen for their durability and serviceability, ensuring long operational life and minimal downtime.

Dual-Wheel Synchronous Coloring

One of the most distinctive features of the TH-630 is its dual-wheel synchronous dyeing system. This design allows the machine to apply oil-based dye simultaneously to both edges of a leather strip. By maintaining perfectly synchronized movement between the left and right dyeing wheels, this system ensures symmetrical, uniform coloring regardless of the material’s thickness or stiffness. Each wheel rotates at a controlled speed, drawing dye from a reservoir and applying it evenly to the edges. The synchronized mechanism minimizes operator error and guarantees consistent color on both sides throughout the entire strip . This feature is particularly useful when producing symmetrical components such as belts, fashion straps, luggage parts, and any other application where both edges of a leather piece will be visible in the final product. It also eliminates the need for multiple passes or manual flipping, improving both efficiency and precision.

Arc-Toothed Coloring Wheel Technology

The TH-630 features arc-shaped toothed coloring wheels, a patented design that sets this model apart from traditional dyeing machines. These wheels provide several benefits:

-

Uniform Dye Application:

The arc surface conforms better to the natural curves and surfaces of leather strips, especially if they are slightly irregular. This ensures a more even application across the full edge width. -

Improved Dye Penetration:

The toothed profile holds and distributes dye consistently, allowing deeper absorption into the leather’s pores. This results in a more durable and richly colored edge. -

Non-slip Surface Contact:

The toothed wheel maintains consistent contact with the edge, reducing slippage and uneven strokes common with flat wheels or manual dyeing techniques. -

Self-cleaning Groove Design:

As the wheels rotate, the toothed pattern helps channel excess dye away from the surface, preventing pooling or over-saturation that could lead to drips and waste.

This unique wheel structure not only improves output quality but also reduces the need for touch-up work or secondary processing.

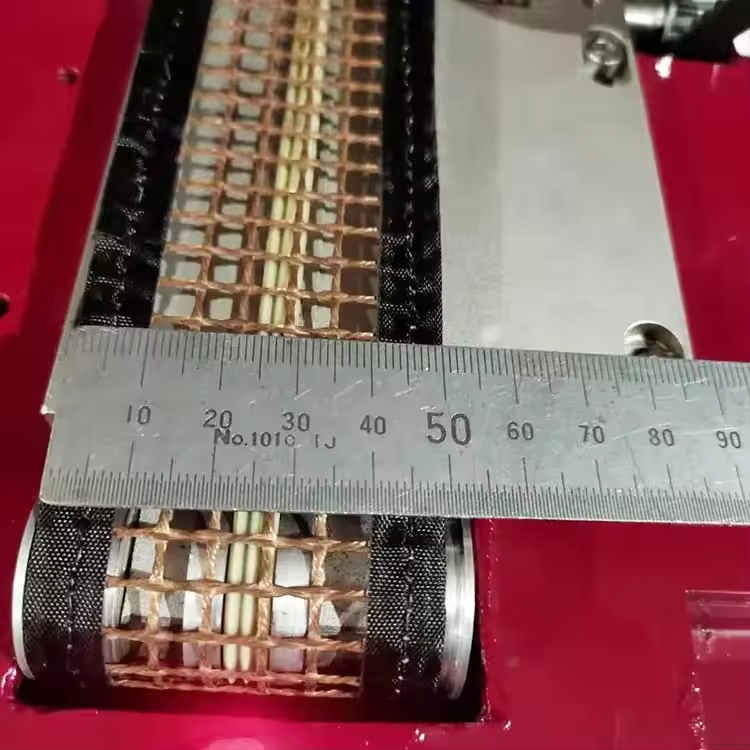

Adjustable Width Range (5-40mm)

The machine accommodates leather strips ranging from 5mm to 40mm in width, making it exceptionally versatile. This wide adjustment range allows operators to handle everything from narrow watch straps and wristbands to broad belts and shoulder harnesses. Adjustment is intuitive and tool-free, enabling quick switching between different strip sizes during batch processing. The machine’s adjustment system locks securely in place, ensuring the strip remains properly centered throughout the dyeing cycle. This flexibility makes the TH-630 suitable for both artisan studios that produce diverse products and industrial workshops running production lines with variable component sizes.

High-Efficiency 150W Motor

At the core of the TH-630 is a 150-watt precision motor, chosen for its high torque, stable output, and low maintenance requirements. This motor provides ample power for continuous operation, even when dyeing dense or thick leather components. Despite its power, the motor is energy-efficient, helping reduce long-term electricity costs. Its smooth torque delivery ensures stable wheel rotation, which is critical for uniform dye application. The motor operates quietly and with minimal vibration, supporting a safe and comfortable working environment for prolonged use.

Voltage Compatibility (220V)

The TH-630 operates on a 220V electrical system, standard in many industrial and international regions. It is plug-and-play ready for workshops equipped with 220V outlets and does not require additional voltage transformers or adapters in compatible regions. For regions with different power specifications, the machine can be adapted via step-down converters or customized configurations upon request. This compatibility makes the TH-630 a viable solution for global manufacturers and exporters.

Compact and Ergonomic Design

Despite its robust performance, the TH-630 maintains a relatively compact form factor with dimensions of 500mm x 460mm x 400mm. It can be easily accommodated on standard workshop benches or production tables without occupying excessive space. Its 40kg weight contributes to overall stability during operation while still allowing the unit to be relocated if needed. Integrated handles or side grips may be included to facilitate repositioning or maintenance. All controls and adjustments are front-facing and easily accessible, making the machine ergonomic for both right-handed and left-handed operators. Clear labeling and intuitive operation ensure minimal training requirements for new users.

Precision, Efficiency, and Aesthetic Excellence

The TH-630 is engineered not just for speed, but for quality. It produces aesthetic, clean, and uniform edge finishes that meet the highest standards of craftsmanship. Whether the end product is a luxury belt, a branded leather bag, or an elegant piece of home decor, the TH-630 ensures the dyed edges match the quality of the overall item. Its ability to deliver consistent color depth, clean boundaries, and no blotches or overspray significantly reduces the need for post-processing and rework. This directly translates into reduced production costs and increased throughput.

Operational Simplicity

Though highly capable, the TH-630 is designed to be easy to operate. With simple width adjustment, dye reservoir filling, and wheel cleaning protocols, the machine can be managed by entry-level staff or expert artisans alike.

Step-by-step operating procedures typically involve:

-

Adjust the wheel gap and width guide to fit the leather strip.

-

Filling the dye reservoirs or applying dye to the wheels.

-

Powering the machine and feeding the strip through the rollers.

-

Inspecting the finished edges for color consistency.

The process is fast, predictable, and highly repeatable, making it ideal for batch production environments.

Maintenance and Longevity

The TH-630 is designed for long-term use and easy maintenance. Key components such as the dyeing wheels, drive belts, and motor brushes are replaceable, and the machine’s modular design facilitates straightforward servicing.

Regular maintenance recommendations include:

-

Cleaning dye wheels and reservoirs after each use to prevent clogging.

-

Inspecting wheel alignment and torque monthly.

-

Checking motor bearings and lubricating as required.

-

Replacing worn toothed wheels after extended operation cycles.

A proper maintenance schedule can extend the life of the machine significantly and ensure consistent output across years of service.

Use Cases and Industry Applications

The TH-630 Horizontal Bilateral Dyeing Machine is suitable for:

-

Leather accessory makers produce belts, straps, and harnesses.

-

Luxury fashion brands offering bespoke leather goods.

-

Industrial leather product manufacturers require edge uniformity.

-

Workshops creating batch-processed leather parts.

-

Educational and training institutions teaching leather craftsmanship.

Its high performance and reliability make it an ideal centerpiece for any operation where edge aesthetics are a priority.

The TH-630 Horizontal Bilateral Dyeing Machine is a powerful and reliable tool built for professionals in the leatherworking, fashion, and industrial accessory fields. With dual-wheel synchronous coloring, arc-toothed wheels, and adjustable width support, it is capable of delivering world-class edge dyeing on a wide variety of leather products. Its compact design, efficient motor, and intuitive operation ensure ease of use and integration into any workflow, from artisan studios to industrial assembly lines. Whether producing one-of-a-kind masterpieces or thousands of leather strips daily, the TH-630 offers the perfect balance of performance, precision, and durability.

No posts found