ARC SINGLE WHEEL DYEING MACHINE TH-628

MACHINE NAME: ARC SINGLE WHEEL DYEING MACHINE

MODEL NO: TH-628

BRAND: TENGHONG

FEATURES

- This product is suitable for oil edge dyeing of small leather items, wristbands, straps, leather accessories, zipper tails, and other product. It is specifically designed for materials with curved edges, circular edges, and small corners. Power 0.15kw

TECHNICAL PARAMETER

- Voltage : 220V

- Power : 25w

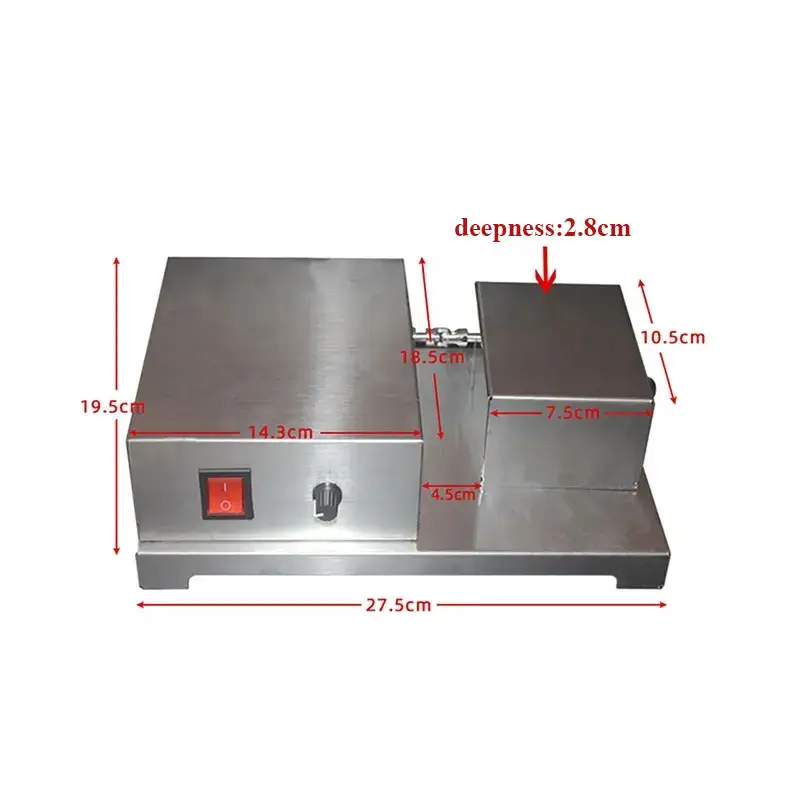

- Dimension : 196*275*90mm

- Weight : 1.8kg

The TH-628 Arc Single Wheel Dyeing Machine is a specialized device designed for oil edge dyeing of small leather items, wristbands, straps, leather accessories, zipper tails, and similar products. Its unique design caters specifically to materials with curved edges, circular edges, and small corners—areas that demand precision and careful handling to achieve flawless finishes. Engineered for artisans, manufacturers, and craftsmen who require superior edge finishing quality, the TH-628 offers a perfect blend of power, control, and convenience in a compact form factor. Its electric single-wheel mechanism ensures consistent dye application while allowing users to maintain manual control over the product, making it ideal for detailed and delicate work.

Product Overview

In leatherworking and fabric processing, the finishing of edges plays a critical role in defining product aesthetics and durability. Traditional manual edge dyeing methods often lead to inconsistent results and high labor intensity, particularly when dealing with complex shapes like curves and small corners. The TH-628 addresses these challenges by providing a semi-automated solution designed to improve precision and efficiency. Its single rotating dye wheel is powered by a 25-watt motor operating at 220 volts, providing steady and smooth rotation essential for uniform dye application. Compact and lightweight, the machine measures 196mm by 275mm by 90mm and weighs just 1.8 kilograms, making it highly portable and suitable for workshops of all sizes.

Key Features

Specialized for Curved and Circular Edges

The TH-628 is engineered specifically for oil edge dyeing on materials with curved or circular edges, as well as tight corners. These shapes are traditionally challenging because dye tends to accumulate unevenly or skip areas. The arc-shaped single wheel dyeing design allows smooth dye application around these contours, ensuring even coverage and a professional finish.

Versatile Application

This machine is ideal for small leather items such as wristbands, straps, leather accessories, zipper tails, and other similar products. Its ability to handle a variety of small components makes it indispensable in leather goods manufacturing, accessory production, and repair shops.

Electric-Powered Consistency

Equipped with a 25-watt motor and operating on a 220V power supply, the TH-628 maintains consistent wheel speed and torque, ensuring steady dye application across the edge length. This consistency is key to achieving high-quality finishes and reducing waste caused by uneven dyeing.

Compact and Lightweight Design

With dimensions of 19627590mm and a weight of 1.8kg, the TH-628 is easy to handle and move around. Its compact footprint allows for easy integration into small workbenches or crowded workshops without sacrificing stability during operation.

Simple Operation

The machine is designed for user-friendly operation, minimizing training requirements. Operators simply need to power on the device and guide the leather or fabric edge along the rotating dye wheel, ensuring smooth and precise dyeing.

Durable Construction

The TH-628 is constructed from quality materials that resist wear and tear from regular use. Its dye wheel and motor assembly are built to withstand continuous operation, delivering long-term reliability.

Detailed Product Description

The TH-628 Arc Single Wheel Dyeing Machine represents an innovative approach to edge finishing in leather and fabric manufacturing. Its design focuses on precision and adaptability, addressing the common difficulties encountered with curved edges and small corners. The core of the machine is its arc-shaped dye wheel, which rotates at a controlled speed powered by a low-wattage electric motor. Unlike manual dyeing methods that rely entirely on operator skill and endurance, the rotating wheel provides consistent application pressure and coverage. Users guide the edge of the product—be it a wristband, strap, or zipper tail—along the spinning wheel, allowing the dye to evenly coat the oil edge. The arc shape of the wheel facilitates natural maneuvering around curved surfaces, preventing blotches, streaks, or uneven dye patches that can degrade product appearance. Thanks to its semi-automatic operation, the TH-628 enables artisans to work faster and with less physical strain, while maintaining the craftsmanship quality required in fine leather and accessory production.

Applications

The TH-628 excels in various practical scenarios:

Leather Crafting

-

Wristbands and Straps: These often feature curved or rounded edges that require uniform oil dye application to prevent roughness or color inconsistency. The TH-628’s arc wheel matches the natural curve of these items, delivering impeccable finishes.

-

Leather Accessories: Key holders, zipper pulls, and decorative trims benefit from precise edge finishing, enhancing both aesthetics and durability.

-

Small Components: Zipper tails and other miniature leather pieces pose a challenge for manual dyeing due to their size and shape, but the TH-628 provides controlled, consistent dye coverage.

Fabric and Substrates

-

Beyond leather, the TH-628 can be used on appropriate fabric edges and substrates that require oil edge dyeing, extending its usefulness in accessory manufacturing and custom fabric work.

Repair and Customization

-

Leather repair shops and customization services find the TH-628 invaluable for restoring or enhancing the edges of existing products, achieving professional results in less time.

Advantages and Benefits

Precision on Complex Edges: The arc wheel design is ideal for working on challenging edges, ensuring dye coverage is uniform even on tight curves and small corners.

Labor Savings and Efficiency: By automating the rotation of the dye wheel, the TH-628 cuts down the time and effort needed for edge dyeing compared to manual techniques.

Consistent High Quality: The electric motor provides a stable rotational speed, preventing the uneven application often seen in hand-dyeing.

Portability and Space Efficiency: Its lightweight and compact dimensions mean it can be easily moved or stored, suitable for both small workshops and mobile artisans.

User-Friendly Operation: Minimal training required; the machine’s straightforward controls make it accessible to a range of skill levels.

Durability: Built with quality materials to endure the rigors of frequent use, making it a dependable tool in any leather or fabric finishing operation.

How It Works

The TH-628 operates by powering a single dye wheel to rotate steadily at a consistent speed. The wheel is pre-treated or applied with oil-based dye suitable for edge finishing. The operator manually presses the leather or fabric edge against the rotating wheel, moving the material steadily along the edge length. The wheel’s arc shape naturally fits curved and circular edges, allowing smooth passage without interruption or excessive pressure. The combination of electric rotation and manual guidance enables controlled, even dyeing, preserving the integrity of delicate edges while producing a deep, rich finish.

User Experience

Operating the TH-628 is simple and intuitive:

-

Setup: Place the machine on a flat surface and connect it to a 220V power source.

-

Prepare the Dye Wheel: Apply appropriate oil-based edge dye to the wheel or ensure the wheel is pre-treated.

-

Power On: Switch on the motor to start the dye wheel rotation.

-

Edge Dyeing: Gently guide the leather or fabric edge along the wheel, keeping steady pressure and speed to ensure even coverage.

-

Finishing: After the edge is dyed, allow drying as per dye instructions before further processing.

Operators appreciate how the machine reduces physical effort compared to fully manual dye wheels, allowing longer work periods without fatigue. The compact size means it fits easily into any workspace, and the machine’s quiet operation adds to a comfortable working environment.

Maintenance and Care

To maintain optimal performance and extend the lifespan of the TH-628:

-

Cleaning: Regularly clean the dye wheel and surrounding parts to prevent dye buildup that could impair smooth operation. Use solvents or cleaning agents compatible with the dye and machine materials.

-

Inspection: Check the motor, wiring, and mechanical assemblies periodically for signs of wear or damage. Replace worn wheels promptly to maintain quality.

-

Storage: When not in use, cover the machine to protect it from dust and moisture. Store it in a dry environment to prevent rust or corrosion.

-

Dye Compatibility: Use only recommended oil-based dyes compatible with the wheel and machine components to avoid damage.

By following these guidelines, the TH-628 will remain a reliable and effective tool for precision edge dyeing.

Safety Considerations

The TH-628 includes several safety features and best practices:

-

Stable Design: The machine’s size and weight provide a steady base that reduces the risk of tipping during use.

-

Protective Components: Moving parts are shielded to prevent accidental contact with fingers or loose clothing.

-

Electrical Safety: The device complies with electrical safety standards for 220V operation, including protections against overcurrent or short circuits.

-

Operator Precautions: Users should wear gloves and protective eyewear when handling dyes and avoid direct skin contact.

Adhering to safety protocols ensures a secure working environment and protects users from potential hazards.

Ideal Users

The TH-628 Arc Single Wheel Dyeing Machine is perfect for:

-

Leather Artisans: Those producing finely crafted wristbands, straps, and accessories.

-

Small and Medium Manufacturers: Workshops requiring efficient edge dyeing for batch production.

-

Repair and Custom Shops: Businesses focusing on the restoration and customization of leather goods.

-

Vocational Training Centers: Institutions teaching leatherworking techniques.

-

Fabric and Accessory Producers: Companies working on substrates or fabric components requiring edge dyeing.

Comparison with Other Edge Dyeing Tools

Compared to fully manual dye wheels, the TH-628 offers the advantage of motorized rotation, reducing labor and improving dye consistency. When compared with larger industrial dyeing machines, it excels in portability and specialized precision for small, curved items. Its unique arc single wheel design specifically targets the needs of curved edges and small corners, which many flat or multi-wheel machines cannot effectively handle.

Customization and Accessories

The TH-628 can be paired with various oil-based dyes suitable for different materials and finish types. Users may also opt for different dye wheel surfaces depending on the dye formula or edge texture required. Custom stands or mounting bases can be designed for fixed installation in workshops, increasing stability during intensive use.

Customer Support and Warranty

The TH-628 is backed by the manufacturer's support offering:

-

Technical assistance for setup and operation.

-

Warranty coverage for defects in materials or workmanship.

-

Spare parts availability, including replacement dye wheels and motors.

-

Guidance on maintenance best practices.

The TH-628 Arc Single Wheel Dyeing Machine represents a powerful yet compact solution for high-quality oil edge dyeing of leather goods, straps, wristbands, zipper tails, and other small products. Its precision arc wheel design, reliable motorized rotation, and user-friendly operation make it an indispensable tool for leatherworkers and accessory producers focused on craftsmanship and efficiency. Whether in a boutique workshop or a medium-scale manufacturing setup, the TH-628 delivers consistent, professional finishes on challenging curved and circular edges. Its combination of portability, precision, and durability ensures it will remain a valued asset for years to come.

No posts found