Pneumatic Sole Attaching Machine TH-586A

In the ever-evolving landscape of footwear manufacturing, the demand for precision, efficiency, and adaptability is paramount. The TH-586A Pneumatic Sole Attaching Machine emerges as a solution tailored to meet these demands, offering a blend of advanced technology and user-centric design. This machine is engineered to streamline the sole attaching process, ensuring consistent quality and enhanced productivity across various shoe types.

Key Features

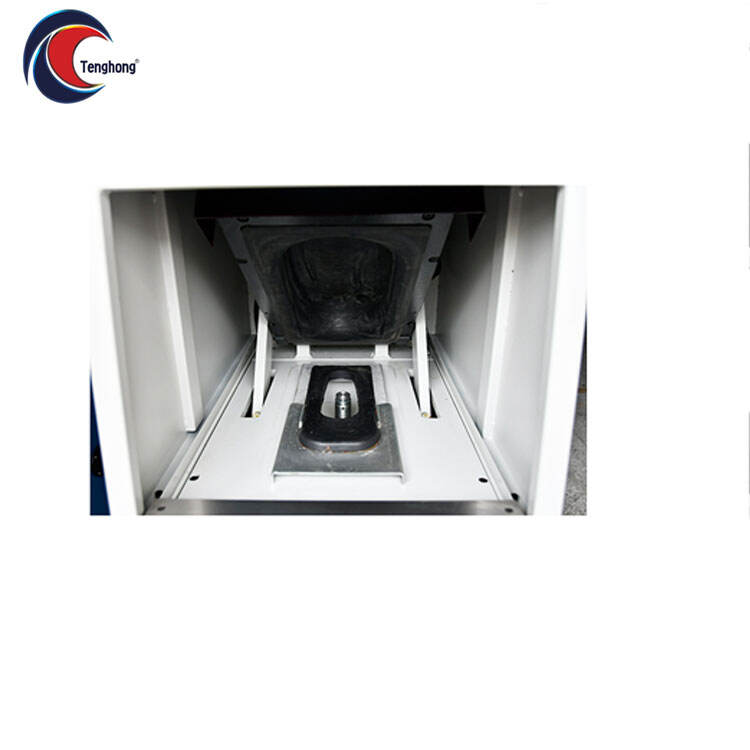

Adjustable Shoe Height Functionality

The TH-586A is equipped with a mechanism to adjust the shoe's height, accommodating a diverse range of footwear designs. This feature ensures:

-

Versatility: Suitable for various shoe styles, including sports shoes, leisure shoes, and those with large or smooth soles.

-

Safety Compliance: The operation mode adheres to safety standards, minimizing the risk of damage to both the product and the operator.

Dual Operation Modes: Automatic and Manual

To cater to different production needs and operator preferences, the machine offers two distinct modes:

-

Automatic Mode:

-

Procedure: Place the shoe in the designated position. Once the operator's hands leave the work area, the cover automatically closes, and air is introduced simultaneously.

-

Efficiency: The machine operates based on preset timings, ensuring consistent pressure application and bonding quality.

-

-

Manual Mode:

-

Procedure: Position the shoe correctly and press the work buttons after removing your hands from the work area.

-

Control: Offers operators direct control over the pressing process, suitable for specialized or delicate tasks.

-

Dual Pressure System for Enhanced Bonding

The TH-586A incorporates a two-stage pressure mechanism:

-

First Pressure: Ensures the entire sole is uniformly packed, establishing initial adhesion.

-

Second Pressure: Applies additional force to firmly bond the upper and sole, resulting in a durable and high-quality finish.

This dual-pressure approach guarantees a robust bond, enhancing the longevity and performance of the footwear.

Technical Specifications

-

Voltage: 220V / 50Hz

-

Power Consumption: 0.2 kW

-

Air Pressure Requirement: 0.6 MPa

-

Compression Time: Adjustable from 0 to 99 seconds

-

Work Efficiency: Capable of processing up to 1,500 pairs in an 8-hour shift

-

Net Weight: 275 kg

-

Package Weight: 300 kg

-

Machine Dimensions: 520 mm (Length) × 850 mm (Width) × 1,660 mm (Height)

-

Packing Dimensions: 650 mm (Length) × 920 mm (Width) × 1,950 mm (Height)

Advantages in Production

Implementing the TH-586A in your manufacturing process offers several benefits:

-

Increased Throughput: The machine's efficient operation enables higher production rates.

-

Consistent Quality: Uniform pressure application ensures each product meets quality standards.

-

Versatility: Accommodates various shoe designs, enhancing production flexibility.

-

Reduced Labor Costs: Automation decreases the need for manual labor, leading to cost savings.

Applications

The TH-586A is ideal for:

-

Footwear Manufacturers: Seeking to enhance production efficiency and product quality.

-

OEM/ODM Operations: Requiring flexible machinery capable of handling multiple designs and specifications.

-

Factories Emphasizing Quality Control: Where consistency and precision are critical to brand reputation.

The TH-586A Pneumatic Sole Attaching Machine embodies the fusion of technology and practicality. Its advanced features, coupled with user-centric design, make it a formidable tool in modern footwear manufacturing. By integrating this machine into your production line, you position your operations at the forefront of efficiency, quality, and innovation.

No posts found