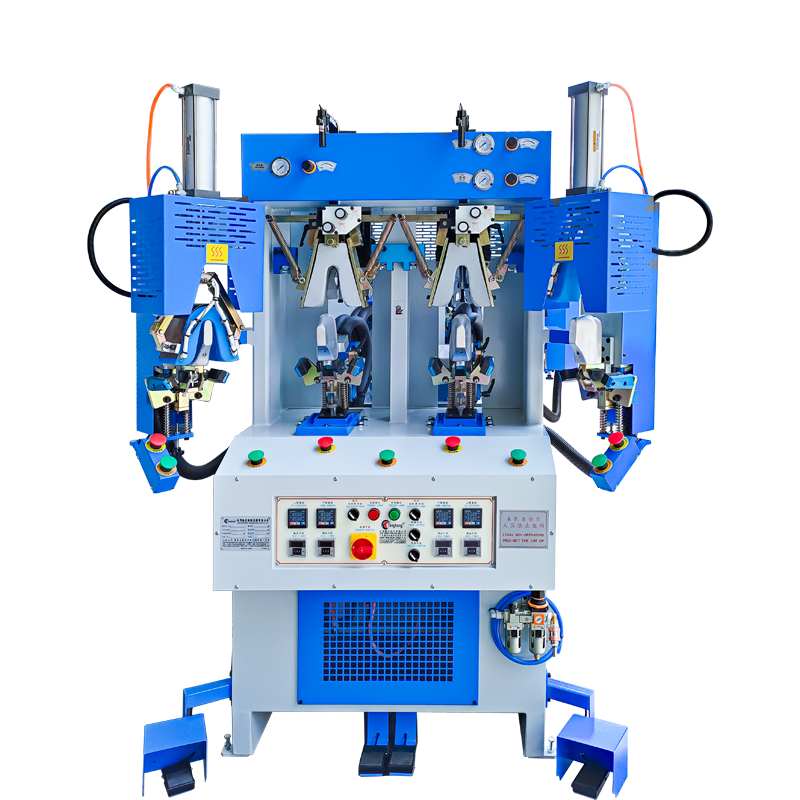

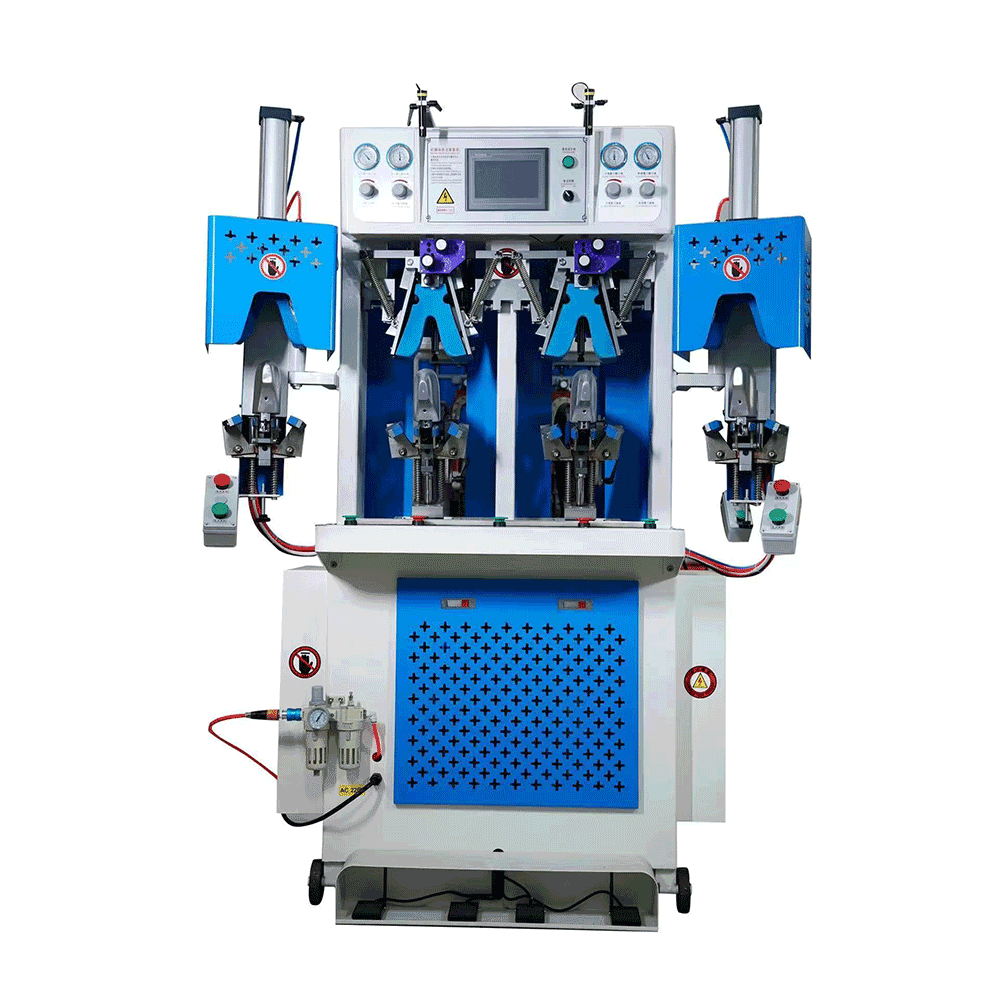

Two Cold And Two Hot Counter Moulding Machine For Stitch-down Shoes TH-319

The TH-319 Two Cold and Two Hot Counter Moulding Machine for Stitch-down Shoes is a cutting-edge solution in the shoe manufacturing industry, designed to provide high-precision, automated, and efficient counter moulding for various styles of footwear, especially stitch-down constructions. This machine combines heat and cold treatment using dual hot and cold systems, achieving perfectly molded uppers and counters that are smooth, tight, and professionally shaped. It is the ideal choice for high-end shoemakers seeking impeccable form retention, consistent output, and ergonomic operation. Built with a sturdy design and packed with automation features, the TH-319 offers versatility with two distinct operation modes—manual and programmable logic controller (PLC) driven. This adaptability gives manufacturers complete control over the moulding process while ensuring uniform shaping results. Whether the user prefers hands-on control or a more automated and systematic approach, this molding machine delivers outstanding functionality in both modes.

Main Features and Functional Description

Dual Operation Modes: Manual and PLC-Driven

The TH-319 is available in two configurations: manual and PLC-integrated. The manual version allows for traditional operation, giving operators full physical control of the moulding functions. This is ideal for small-batch production, prototype manufacturing, or custom shoe making where intricate attention to detail is required. The PLC-based model offers advanced automation, allowing users to pre-program operating parameters for consistent and repeatable moulding cycles. This mode is ideal for large-scale operations where productivity, precision, and uniformity are critical. With the touch of a few buttons, operators can set temperature ranges, cooling cycles, and grip jaw pressures, reducing human error and boosting efficiency.

Independent Dual Heating and Cooling Systems

At the heart of the TH-319’s performance is its innovative two-hot and two cold station setup, each functioning independently to allow simultaneous heating and cooling of the shoe’s upper and counter region. This design not only increases throughput but also minimizes the time needed for each operation cycle. The heating system uses electronically controlled heating elements, capable of reaching temperatures up to 200°C. This system ensures precise heating of the shoe counter area, effectively activating thermoplastic toe puffs and linings. It facilitates the perfect softening of materials, which is crucial for proper forming and adhesion to the last . Complementing the heat stations, the dual cold stations utilize an environmentally friendly refrigeration system that can reach freezing temperatures down to -30°C. This rapid cooling mechanism sets the material in place quickly, locking the shape into the desired contour and preventing relaxation or distortion of the components. The ability to heat and cool in tandem across multiple molds significantly speeds up production and ensures the vamp, lining, and counters retain their form, free of bubbles, wrinkles, or any type of deformation.

Adjustable Pull-Down Grip Jaw System

Another key innovation in the TH-319 machine is the adjustable pull-down grip jaw. This mechanism ensures the upper of the shoe is securely and precisely pulled down over the last before the moulding process begins. It eliminates slack, wrinkles, and air pockets, which are common problems in poorly executed counter moulding. The grip jaw pressure is adjustable based on the shoe size and material thickness, providing flexibility in operation. Whether working with soft leather, synthetic materials, or mixed-texture uppers, the grip jaw can be tuned for optimal results. This adaptability helps achieve a seamless and uniform joint between the vamp and last, laying the foundation for a well-shaped and durable shoe.

Quick and Easy Mold Loading and Unloading

The mold exchange mechanism in the TH-319 is designed for quick and efficient loading/unloading, allowing minimal downtime during shift changes or between different shoe models. Operators can easily remove and install custom molds, making the machine highly adaptable for various designs, including men’s, women’s, and children’s footwear. Because molds can be customized, manufacturers have the flexibility to cater to bespoke shoe designs or specific market demands. Once the mold is secured, the machine ensures that the shoe upper conforms perfectly to its contours, achieving a sharp, elegant, and professional finish.

Tilting Mold Design for Operator Convenience

To further enhance usability, the mold platform is tiltable, which provides better access during the loading and unloading of the shoe upper. This ergonomic feature reduces strain on the operator’s arms and wrists, streamlining the workflow and contributing to better health and safety standards on the production floor. This tilt capability also allows operators to visually inspect the mold and shoe upper alignment before the heat or cold cycle is initiated. This leads to fewer mistakes and more consistently excellent results.

Environmentally Friendly Refrigeration System

The TH-319 is equipped with a green refrigeration system, built to meet modern environmental standards without sacrificing performance. It uses eco-friendly refrigerants that are non-toxic, non-flammable, and compliant with global environmental safety regulations. In addition to being sustainable, this system offers fast cooling cycles that rapidly bring the shoe counter temperature down after heating. This temperature shock process enhances shape retention and contributes to the creation of long-lasting footwear with superior form fidelity.

High-Precision Electronic Heating System

The heating units are controlled via a microelectronic processing system that ensures precise and consistent heat delivery to each mold. Unlike traditional systems that rely on analog thermostats, the TH-319 can maintain target temperatures with minimal deviation, which is essential for maintaining material properties during forming. The maximum heating temperature reaches 200°C, which is sufficient to activate and soften even the most robust thermoplastic toe puffs. The result is a pliable material ready to conform exactly to the mold’s shape. At the end of the heating cycle, the cooling unit locks the softened material into place, producing a clean, wrinkle-free, and professional shoe upper every time.

Rubber Sheet Downward Pressing Action

The rubber sheet pressing system provides uniform downward pressure on the shoe upper during moulding. This action presses the softened materials snugly against the last and mold, ensuring the liner, toe puff, and vamp are tightly and seamlessly joined. This technique eliminates air bubbles, crinkling, and material gaps, contributing to the overall quality and longevity of the final product. The rubber sheet mechanism is especially effective in complex shoe designs, where multiple materials and layers are involved. It adjusts pressure dynamically, ensuring delicate materials are not crushed while still achieving firm bonding.

Post-Moulding Excellence: Zero Deformation and Maximum Adhesion

After each cycle, the shoe upper emerges from the TH-319 perfectly molded. The liner, counter, and vamp are seamlessly integrated without any of the common post-forming issues such as bubbling, crimping, or deformation. Thanks to the precise synchronization of heat, pressure, and cooling, the TH-319 ensures each shoe not only looks flawless but also maintains its shape through wear and tear. This results in shoes that fit better, last longer, and exhibit high aesthetic standards that are crucial in competitive retail environments.

Product Benefits Summary

-

High productivity with two heating and two cooling stations operating simultaneously

-

Consistent shaping results due to programmable electronic controls

-

Time-saving and user-friendly operation with tilting molds and quick-change molds

-

Reduced defects due to precise pressure and temperature control

-

Ergonomic and safe design that minimizes operator fatigue

-

Environmentally responsible with eco-refrigerants

-

Customizable molds that adapt to a variety of shoe types and styles

-

Enhanced product quality, free from common forming defects

-

Adaptable operation modes, suitable for small artisan shops or industrial mass production

Ideal Applications and Industries

The TH-319 is specifically designed for the stitch-down shoe manufacturing sector, where the molding of the counter area is critical to the structure and appearance of the footwear. It is especially useful in:

-

High-end leather shoe production

-

Workwear and safety boots manufacturing

-

Children’s and orthopedic shoe shaping

-

Fashion footwear with unique shapes and counter designs

-

Custom and small-batch shoemaking operations

It’s a reliable solution for OEMs, ODMs, and factories seeking to modernize their production lines without compromising the handcrafted quality often associated with luxury footwear.

Reliability and Maintenance

Engineered for industrial-grade durability, the TH-319 features high-quality components that require minimal maintenance. The heating and cooling elements are built to last under continuous operation, and the electronic control system is designed for stability and long-term use. With regular maintenance primarily involving refrigerant checks, clamp lubrication, and filter cleaning, the TH-319 will remain in optimal condition, providing consistent performance shift after shift.

The TH-319 Two Cold and Two Hot Counter Moulding Machine for Stitch-down Shoes is more than just a forming device—it is a precision tool that enhances the efficiency, quality, and scalability of footwear production. Its dual heating and cooling systems, customizable operation modes, ergonomic features, and eco-conscious engineering make it an indispensable asset in modern shoemaking. By ensuring perfect adhesion, flawless shaping, and a premium finish, the TH-319 elevates your product standard and boosts your manufacturing output. Whether you're running a bespoke workshop or an automated production line, this machine will streamline your operations, improve your shoe quality, and increase your profitability.

No posts found