Two Hot and Two Cold Shoe Toe Moulding Machine TH-316

The TH-316 Two Hot and Two Cold Shoe Toe Moulding Machine is a high-performance, industrial-grade solution engineered to meet the rigorous demands of modern footwear manufacturing. Designed for both manual and PLC-controlled operations, this machine offers dual-mode functionality to serve varying production environments and user preferences. It seamlessly integrates advanced thermal and cooling technologies to ensure superior moulding precision, improved production efficiency, and consistent product quality. Footwear manufacturing demands a balance of durability, aesthetics, and comfort. In toe cap shaping, a critical step in the shoe production process, precision and material behavior under temperature influence are paramount. The TH-316 addresses this need by combining hot moulding and cold forming mechanisms within one machine. With a robust build, energy-efficient operation, and capability to handle a variety of thermoplastic materials, it stands out as a pivotal asset in any production line.

Dual Configuration: Manual and PLC-Controlled Operation

A defining feature of the TH-316 is its flexibility in operation. It supports both manual and PLC (Programmable Logic Controller) modes, allowing factories to choose the configuration that best suits their operational model.

-

Manual Operation: Ideal for smaller batches or more controlled, operator-focused use. This setup provides the hands-on control some shoemakers prefer for artisan-level production or experimental materials.

-

PLC-Controlled Operation: Offers automation for higher throughput environments. The PLC interface enables programmed sequences, repeatable cycles, consistent quality, and reduced operator fatigue. The intuitive controls also minimize the learning curve for new users.

This dual-mode design enhances the adaptability of the TH-316, making it suitable for both traditional shoemaking operations and modern, high-volume production facilities.

Advanced Thermoplastic Shaping Capability

The TH-316 is engineered to accommodate all types of thermoplastic materials used in shoe upper construction. Whether working with standard synthetic uppers, leather composites, or specialized materials with custom properties, this machine provides the necessary shaping and forming capacity. The upper and toe regions of footwear are often the most critical in terms of aesthetic and structural design. Improper shaping leads to wrinkling, deformation, or discomfort. With the TH-316, users can achieve a smooth, seamless toe cap and upper curvature thanks to precision heat application and calibrated pressure controls.

Dual Hot Mould System for Simultaneous Softening

Unlike traditional toe moulding machines that rely solely on top-down heat application, the TH-316 features two hot moulds — one upper and one lower, which apply steam and heat simultaneously. This dual-action softening process ensures that the entire upper, from the vamp to the toe box, is uniformly conditioned before shaping. The benefits include:

-

Faster softening time

-

Improved upper elasticity

-

Enhanced material response during forming

-

Greater shape conformity

This capability dramatically reduces wrinkling, facilitates easier stretching around the last, and contributes to overall production efficiency.

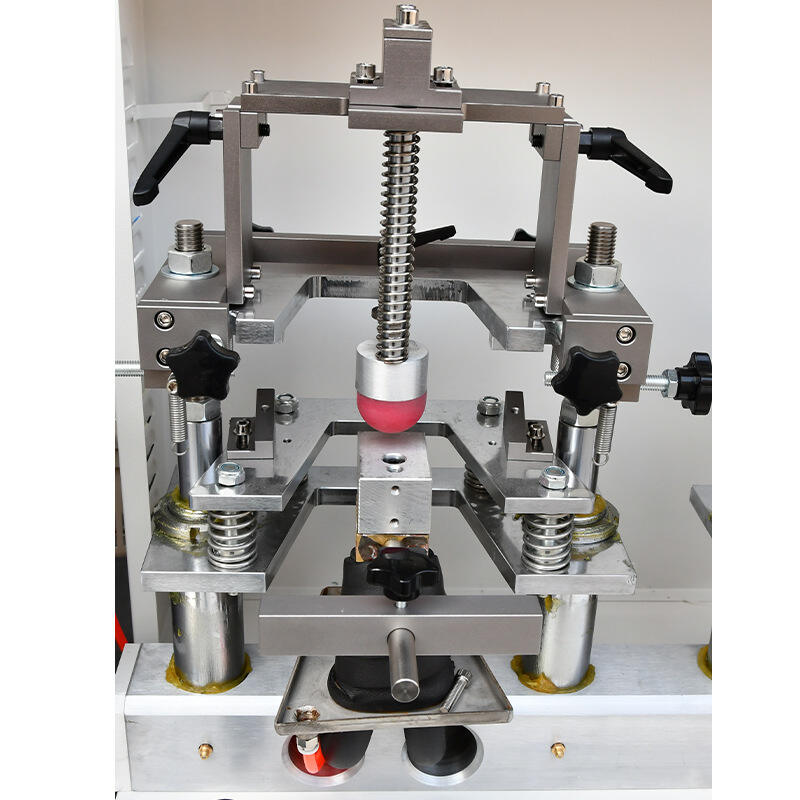

High-Precision Cold Moulding System

After softening, the material is shaped and set using the cold mould clamp system, which is meticulously engineered for high-accuracy results. The mould clamp uses Teflon straps in conjunction with the shoe last to fix the upper in the desired shape during the cooling cycle.

Key benefits include:

-

Minimal slippage and distortion

-

Resistance to high temperatures

-

Non-stick surface for easy release

-

Long-lasting material integrity

Each cold mould is tailored according to the client's specifications, ensuring a snug fit around the last and contributing to the machine’s exceptional 98% accuracy rate in forming the toe cap and front upper section. This level of precision helps reduce rejects and the need for post-moulding adjustments.

Customizable Lasts and Accessories

Recognizing that footwear manufacturers often work with different shoe designs, the TH-316 supports customized lasts and Teflon strap configurations. This feature ensures that each product, regardless of style, gender category, or size range, receives the exact shaping it requires. Custom components are fabricated to precise tolerances, ensuring consistency across different batches. This capacity is particularly important for companies offering bespoke or premium shoes that demand exact replication across pairs.

Integrated Steam Device for Flexibility and Gloss

The hot mould unit is not just a heating element; it’s equipped with a steam generation module that deeply penetrates the upper with controlled high-pressure steam. Steam has several advantages over dry heat:

-

Loosens fibers more thoroughly

-

Reduces material fatigue

-

Makes leather or synthetic materials more pliable

-

Helps maintain the original gloss or shine of materials

By combining temperature with moisture, the steam device enhances the flexibility of the upper and restores natural brightness, leading to a superior final appearance and improved comfort.

High-Efficiency Water Cooling System

Once the upper has been shaped using heat and pressure, rapid cooling is critical to lock in the new shape without compromising material properties. The TH-316 integrates a water cooling system capable of reaching temperatures as low as -30°C. This allows:

-

Immediate setting of the moulded shape

-

Reduction of cycle time between pairs

-

Minimization of material shrinkage or expansion

-

Enhanced durability of the formed structure

The quick cooling phase ensures that the shoe maintains its shape even under stress, such as when worn repeatedly or exposed to different environmental conditions.

Structural Design and Build Quality

The TH-316 is constructed with heavy-duty industrial-grade materials to support long-term operation in factory environments. Its frame provides stability even during prolonged use, and all moving components are precision-engineered to minimize wear and maintenance downtime.

-

Dimensions: 87 cm x 90 cm x 150 cm – Compact enough for space-limited factories, yet robust enough for high-volume output.

-

Weight: 570 kg – Heavy enough to provide stability, especially during simultaneous pressing and steam cycles.

The thoughtful ergonomics of the machine, including accessible control panels, adjustable clamps, and safety mechanisms, ensure that operators can work with ease and minimal fatigue during long shifts.

Electrical and Performance Specifications

The TH-316 runs on a standard 220V power supply, making it compatible with most industrial setups. With a power consumption of 4 kW, it is energy-efficient given its capabilities.

Performance highlights:

-

Capacity: Up to 1600 pairs per 8-hour shift

-

Cycle Time: Optimized for rapid throughput without sacrificing precision

-

Energy Consumption: Balanced thermal management system that minimizes waste

Safety and Reliability

Safety is paramount in industrial machinery. The TH-316 incorporates:

-

Temperature control sensors to prevent overheating

-

Pressure regulation systems in steam generation

-

Emergency stop controls are accessible to the operator

-

Thermal insulation in key areas to avoid operator burns

With minimal risk of overheating or mechanical malfunction, the machine ensures continuous operation and protects both the product and personnel.

Maintenance and Longevity

Routine maintenance of the TH-316 is straightforward:

-

Steam unit cleaning is simplified with a modular design

-

Cooling system components are accessible for flushing and descaling

-

Teflon straps and lasts are easy to replace or upgrade

Designed for high durability, most components have a lifespan that exceeds industry averages, making the machine a sound long-term investment.

Environmental Considerations

In addition to efficiency, the TH-316 is environmentally conscious:

-

Low water consumption in steam generation

-

Energy-efficient cooling system

-

Minimal emissions due to clean electric heating

-

Reduced material waste thanks to high forming accuracy

Companies looking to align with environmental sustainability goals will find the TH-316 a responsible addition to their operations.

Industry Applications

This machine is ideal for:

-

Mass-production footwear manufacturers

-

Custom shoe designers

-

Industrial and safety shoe producers

-

Military or specialty footwear makers

-

Fashion brands with premium product lines

Applicable for multiple footwear types, including:

-

Dress shoes

-

Leather boots

-

Safety shoes

-

Children’s footwear

-

Orthopedic and medical shoes

Why Choose the TH-316?

When compared to traditional moulding equipment, the TH-316 excels in several ways:

-

Faster production cycles

-

Enhanced moulding accuracy

-

Dual thermal system for better material conformity

-

Superior cooling for shape retention

-

Customizability for a wide range of designs

Whether you’re looking to upgrade an old production line or outfit a new facility, the TH-316 offers unmatched performance, reliability, and flexibility in one powerful package.

The TH-316 Two Hot and Two Cold Shoe Toe Moulding Machine is more than a simple production device; it's a precision tool that embodies engineering excellence, production efficiency, and product quality. From its dual hot moulding units with steam softening, to the rapid cold clamping system and customizable components, every aspect is designed to meet the highest standards in modern shoemaking. For businesses aiming to elevate their manufacturing capabilities, improve shaping quality, reduce cycle times, and minimize manual errors, the TH-316 stands as an essential investment. Its durability, versatility, and performance will serve as a cornerstone in your production line for years to come.

No posts found