Intelligent hydraulic Embossing machine

The Hydraulic Automatic Feeding Cutting Machine represents a significant advancement in industrial cutting technology, combining precision, efficiency, and versatility. Designed to meet the diverse needs of modern manufacturing, this machine is engineered for high-performance applications across various industries, including automotive, textiles, electronics, and packaging.

Versatile Material Compatibility

Our hydraulic automatic feeding cutting machine is adept at processing a wide array of materials, making it a valuable asset in multiple sectors. The materials it can handle include:

-

Plastics: Vacuum-formed plastics, PVC, PC, and soft PU foam.

-

Textiles: Fabrics, carpets, and composite boards.

-

Leather Products: Leather bags, boots, and other accessories.

-

Electronics: Circuit boards and nameplates.

-

Packaging Materials: Sticky paper and double foam shells.

-

Automotive Components: Car stepping boards and combined pictures.

This extensive material compatibility ensures that the machine can cater to a broad spectrum of manufacturing needs.

Advanced Hydraulic System

The core of the machine's performance lies in its advanced hydraulic system, which offers:

-

High Precision: Ensures consistent cutting force for accurate results.

-

Energy Efficiency: Optimized design reduces power consumption.

-

Durability: Built to withstand the demands of continuous operation.

The hydraulic system's reliability contributes to the machine's overall performance and longevity.

Automatic Feeding Mechanism

Equipped with an automatic feeding system, the machine enhances productivity by:

-

Consistent Material Feeding: Guarantees uniform material flow for precise cuts.

-

Adjustable Feeding Speed: Allows customization based on material type and thickness.

-

Reduced Manual Intervention: Minimizes labor requirements and human error.

This automation streamlines the cutting process, leading to increased efficiency.

Precision Cutting Capabilities

Achieving high precision is crucial in many manufacturing processes. Our cutting machine offers:

-

Accurate Cutting Depth Control: Ensures uniform cuts across the material.

-

Minimal Tolerance Levels: Guarantees tight tolerances for high-quality products.

-

Smooth Cut Edges: Reduces the need for post-processing.

These capabilities make the machine ideal for applications requiring stringent quality standards.

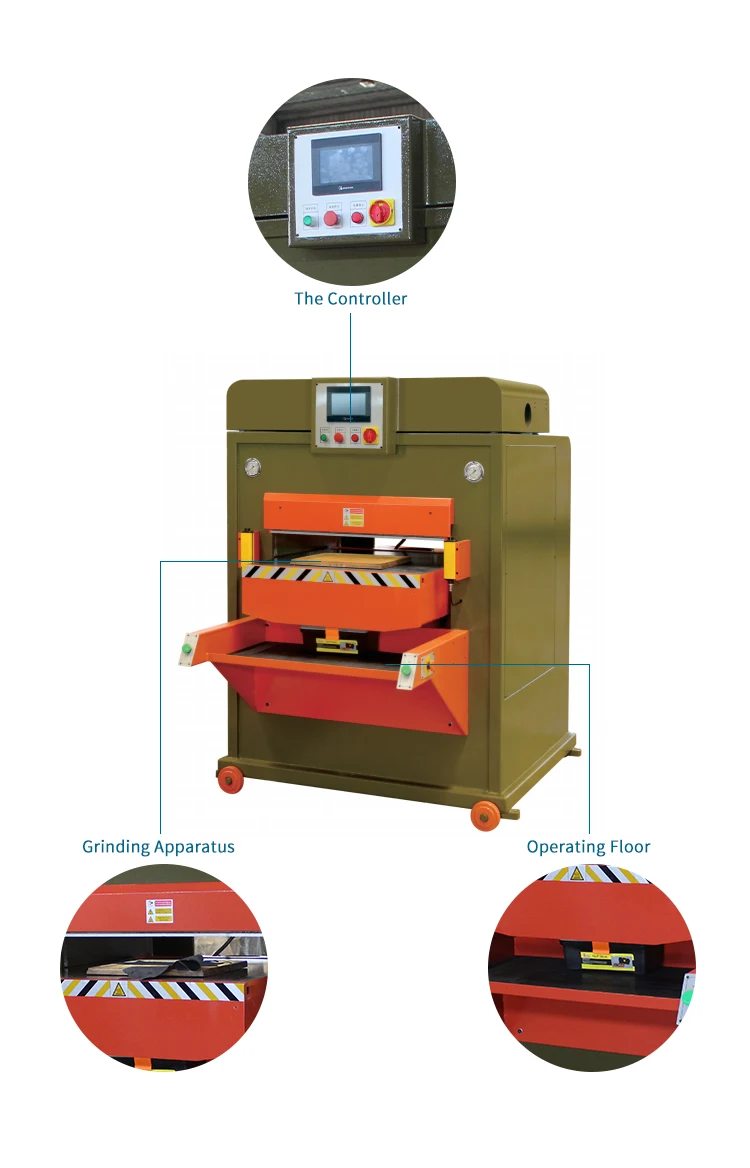

User-Friendly Control Panel

The machine features an intuitive control panel designed for ease of use:

-

Touchscreen Interface: Provides a clear and responsive user experience.

-

Programmable Settings: Allows for customization of cutting parameters.

-

Real-Time Monitoring: Displays operational status and diagnostics.

The user-friendly interface simplifies operation and reduces training time for operators.

Safety Features

Safety is paramount in industrial machinery. Our cutting machine incorporates several safety features:

-

Emergency Stop Button: Allows for immediate cessation of operations in case of emergencies.

-

Safety Interlocks: Prevents machine operation when safety doors are open.

-

Overload Protection: Safeguards against excessive force that could damage the machine or cause injury.

These safety measures ensure a secure working environment for operators.

Robust Build Quality

The machine's construction is designed for durability and longevity:

-

Heavy-Duty Frame: Provides stability during operation.

-

High-Quality Materials: Ensures resistance to wear and tear.

-

Corrosion-Resistant Coatings: Protects against environmental factors.

The robust build quality contributes to the machine's reliability and extended service life.

Energy Efficiency

In today's environmentally conscious world, energy efficiency is a key consideration:

-

Low Power Consumption: Designed to minimize energy usage without compromising performance.

-

Eco-Friendly Components: Utilizes materials and technologies that reduce environmental impact.

-

Compliance with Energy Standards: Meets international energy efficiency regulations.

These features make the machine a sustainable choice for modern manufacturing facilities.

Maintenance and Serviceability

To ensure optimal performance, regular maintenance is essential:

-

Easy Access to Components: Simplifies routine inspections and servicing.

-

Modular Design: Allows for quick replacement of parts.

-

Comprehensive Service Manual: Provides detailed instructions for maintenance procedures.

The machine's design facilitates straightforward maintenance, reducing downtime and service costs.

Applications

The versatility of the hydraulic automatic feeding cutting machine makes it suitable for a wide range of applications:

-

Automotive Industry: Cutting materials for interior components and accessories.

-

Textile Industry: Precision cutting of fabrics and synthetic materials.

-

Packaging Industry: Producing packaging materials and components.

-

Electronics Industry: Cutting circuit boards and other electronic components.

-

Footwear Industry: Cutting leather, rubber, and synthetic materials for shoe production.

This broad applicability underscores the machine's versatility and value across various sectors.

Customization Options

Understanding that different industries have unique requirements, we offer customization options:

-

Specialized Tooling: Tailored dies and blades for specific materials.

-

Software Integration: Compatibility with existing production management systems.

-

Size and Capacity Adjustments: Machines are configured to meet specific production volumes.

These customization options ensure that the machine can be adapted to meet the specific needs of your operations.

Technical Specifications

While specific technical specifications can vary based on customization and model, typical features include:

-

Cutting Force: Ranges from 25 to 300 tons, depending on model.

-

Cutting Area: Varies from 500×500 mm to 1500×1500 mm.

-

Stroke Length: Adjustable to accommodate different material thicknesses.

-

Feeding Speed: Programmable to match material type and cutting requirements.

These specifications provide flexibility to handle a wide range of cutting tasks.

Installation and Setup

Setting up the machine involves several key steps:

-

Site Preparation: Ensuring adequate space and infrastructure for installation.

-

Foundation Requirements: Providing a stable base to support the machine's weight and operation.

-

Electrical and Hydraulic Connections: Properly connecting power and fluid systems.

-

Calibration and Testing: Ensuring the machine operates within specified parameters.

Professional installation services are available to ensure a smooth setup process.

Training and Support

To maximize the machine's potential, we offer:

-

Operator Training: Instruction on machine operation and safety protocols.

-

Maintenance Training: Guidance on routine maintenance and troubleshooting.

-

Technical Support: Access to a dedicated support team for assistance with any issues.

These services ensure that your team is well-equipped to operate and maintain the machine effectively.

Warranty and After-Sales Service

We stand behind the quality and reliability of our hydraulic automatic feeding cutting machine. To provide peace of mind:

-

Warranty Coverage: Offers comprehensive warranty terms to protect your investment.

-

After-Sales Support: Provides ongoing support to address any post-purchase concerns.

-

Spare Parts Availability: Ensures the availability of genuine spare parts for maintenance and repairs.

Our commitment to customer satisfaction extends beyond the initial purchase, ensuring long-term performance and support.

The Hydraulic Automatic Feeding Cutting Machine is a cutting-edge solution designed to enhance productivity, precision, and efficiency in various manufacturing processes. With its advanced features, versatile applications, and robust design

No posts found