Hydraulic Swing Arm Clicking Press Die Cutting Machine TH-120KN

The Hydraulic Swing Arm Clicking Press Die Cutting Machine is a versatile and powerful industrial cutting solution designed for precision die cutting across a broad range of materials commonly used in shoe manufacturing, garment production, packaging, and various other industries. Engineered to deliver consistent performance, this machine is an essential tool for businesses requiring accurate, repeatable, and efficient cutting of materials such as shoe uppers, soles, insoles, leather, rubber, synthetic fibers, fabrics, plastics, and more. By leveraging hydraulic power combined with a swing arm mechanism, this machine ensures robust cutting force, ease of operation, and remarkable precision. It supports high-volume production with reduced operator fatigue, making it an ideal choice for factories and workshops focused on quality and efficiency.

Key Features and Advantages

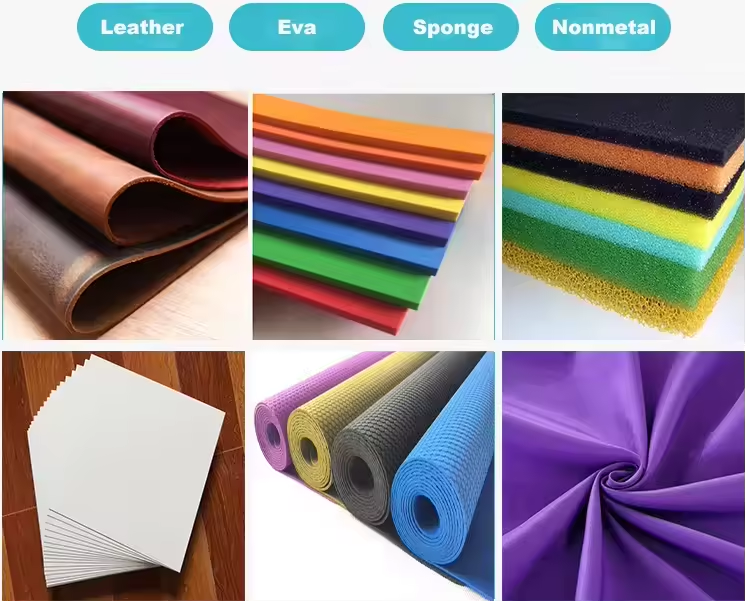

Multi-Material Compatibility

One of the most important strengths of the Hydraulic Swing Arm Clicking Press Die Cutting Machine is its ability to cut a diverse range of materials. This versatility allows manufacturers across different sectors to utilize a single machine for various cutting tasks, significantly reducing capital expenditure and optimizing floor space.

-

Shoe Uppers and Soles: Perfect for shaping leather, synthetic uppers, rubber soles, and insoles with clean and accurate edges.

-

Leather and Rubber: Cuts thick and tough materials effortlessly, ideal for shoe and leather goods production.

-

Chemical Fibers and Synthetic Fabrics: Delivers consistent cutting on modern materials such as nylon, polyester, and other chemically engineered textiles.

-

Cardboard and Paper: Efficiently processes packaging materials, allowing precise die cutting of cardboard, paperboard, and cartons.

-

Fabrics: Suitable for cotton, hemp, canvas, and non-woven fabrics, supporting the garment and upholstery industries.

-

Plastic and Synthetic Bags: Cuts plastic sheets and bags cleanly without deformation.

This broad material compatibility extends the machine’s applicability beyond footwear manufacturing into general industrial, textile, and packaging sectors.

Powerful Hydraulic System with Adjustable Force

At the heart of the machine lies a sophisticated hydraulic system designed to deliver cutting forces ranging from 12 tons up to 20 tons, depending on the model selected. This immense force allows the machine to handle thick and tough materials without compromising cutting quality or consistency.

-

Adjustable Cutting Force: Operators can fine-tune the force based on the thickness and toughness of the material, ensuring optimal cutting without damage.

-

Hydraulic Stability: The hydraulic mechanism provides smooth and steady pressure throughout the cutting stroke, reducing wear on dies and materials.

-

Energy Efficient: Despite its power, the machine’s hydraulic system is designed for efficient energy consumption, balancing high performance with lower operational costs.

Swing Arm Design for Enhanced Accessibility and Safety

The swing arm mechanism is a notable ergonomic feature that sets this machine apart from traditional vertical presses. The arm swings horizontally, allowing easier placement and removal of cutting dies and materials.

-

Improved Operator Safety: The swing arm keeps the operator's hands away from the cutting zone during operation.

-

Convenient Material Loading: Large or awkward materials can be positioned more easily due to the arm’s swing motion.

-

Space Efficiency: The swing arm design requires less vertical clearance compared to standard presses, saving valuable workshop space.

Adjustable Stroke Length and Working Table Dimensions

To accommodate various cutting needs, the machine features an adjustable stroke length between 5 mm to 75 mm, allowing precision cutting depth control.

-

Customizable Stroke: This adjustability ensures clean cuts on thin to thick materials without over-penetration or incomplete cutting.

-

Large Working Table: The generous table surface supports a wide range of material sizes, providing stability and ease during the cutting process.

-

Stable Upper Board: The upper board size is designed to securely hold dies and materials for consistent results.

Robust Construction for Long-Term Durability

Constructed from high-quality materials with precise engineering standards, this machine is built to withstand the demanding environment of industrial production lines.

-

Heavy-Duty Frame: The solid steel frame minimizes vibration and movement, ensuring accuracy and reducing wear.

-

Corrosion Resistance: Key components are treated to resist rust and wear, prolonging machine life and reducing maintenance.

-

Precision Machining: Critical parts are machined with tight tolerances, ensuring consistent performance and easy maintenance.

User-Friendly Operation and Maintenance

The machine’s design takes operator comfort and ease of maintenance into account, reducing downtime and improving overall productivity.

-

Simple Controls: Intuitive operation panels and switches allow quick adjustment of force, stroke, and power.

-

Quick Die Change: The swing arm design facilitates rapid die changes, minimizing production interruptions.

-

Easy Maintenance: Access panels and modular hydraulic components simplify routine service and troubleshooting.

-

Safety Features: Emergency stop buttons and protective guards help prevent accidents and comply with industrial safety standards.

Detailed Technical Specifications

The Hydraulic Swing Arm Clicking Press Die Cutting Machine is available in multiple models to suit different production capacities and application needs. Below is a detailed breakdown of specifications across the popular models:

| Parameter | TH-120KN | TH-140KN | TH-160KN | TH-200KN |

|---|---|---|---|---|

| Cutting Force | 12 Tons | 14 Tons | 16 Tons | 20 Tons |

| Stroke Length | 5-75 mm | 5-75 mm | 5-75 mm | 5-75 mm |

| Working Table Dimensions | 400 mm × 800 mm | 400 mm × 900 mm | 410 mm × 900 mm | 500 mm × 1000 mm |

| Upper Board Size | 350 mm × 450 mm | 350 mm × 450 mm | 350 mm × 460 mm | 350 mm × 550 mm |

| Distance Between Boards | 50-120 mm | 50-140 mm | 50-140 mm | 65-150 mm |

| Power | 1.1 kW | 1.1 kW | 1.1 kW | 1.5 kW |

| Voltage | 220 V AC / 380 V AC | 220 V AC / 380 V AC | 220 V AC / 380 V AC | 220 V AC / 380 V AC |

| Machine Dimensions (L×W×H) | 800 mm × 750 mm × 1350 mm | 900 mm × 750 mm × 1350 mm | 900 mm × 750 mm × 1350 mm | 1000 mm × 900 mm × 1350 mm |

| Weight | 380 kg | 410 kg | 460 kg | 680 kg |

| First Refueling Volume | 36 L | 36 L | 36 L | 54 L |

Model Comparison and Selection Guide

TH-120KN: Entry-Level Power and Precision

The TH-120KN is ideal for small to medium-sized workshops requiring a reliable cutting press capable of handling common materials with a 12-ton cutting force. Its compact size and moderate table dimensions make it suitable for operations with limited space while still providing ample cutting capacity.

TH-140KN: Enhanced Cutting Force for Medium Materials

Stepping up to 14 tons of cutting force, the TH-140KN offers a bit more power for cutting thicker or tougher materials like dense leather or layered fabrics. The slightly larger table supports wider materials, making it suitable for a broader range of applications.

TH-160KN: High Precision for Heavy-Duty Production

The TH-160KN model offers 16 tons of cutting force, excellent for more demanding industrial applications requiring consistent cutting of thicker or composite materials. It balances power and size, making it ideal for medium to large production lines.

TH-200KN: Maximum Force for the Most Demanding Tasks

At 20 tons, the TH-200KN delivers the highest cutting force available in this series. This model is built for heavy-duty applications such as thick rubber soles, multi-layered materials, and tough synthetic composites. Its larger working table and upper board sizes provide flexibility in die size and material dimensions.

Applications and Industry Uses

Footwear Manufacturing

This machine is particularly well-suited for the footwear industry, where materials such as leather, rubber, synthetic fibers, and textile uppers require precise die cutting for components like shoe soles, insoles, and uppers.

-

Shoe Uppers and Soles: Achieves clean, repeatable cuts that ensure perfect fit and finish.

-

Layered Cutting: Capable of cutting multiple layers simultaneously, improving throughput.

-

Variety of Materials: Works efficiently with leather, rubber, chemical fibers, and synthetic uppers.

Textile and Apparel Production

In garment manufacturing, accurate cutting of fabrics like cotton, hemp, canvas, and non-woven materials is essential for creating components such as collars, cuffs, and appliqués.

-

Fabric Cutting: Produces clean edges without fraying.

-

Multi-Layer Cutting: Allows cutting of several fabric layers at once to improve production speed.

-

Precision: Critical for pattern pieces and fabric components that require exact dimensions.

Packaging Industry

Cardboard, paperboard, and plastic bags can be precisely die-cut for packaging components such as boxes, inserts, and covers.

-

Cardboard and Paper: Efficient cutting for packaging prototypes and production.

-

Plastic Bags: Clean cuts without deformation or melting.

Leather Goods and Accessories

From handbags to belts, precise die cutting improves production quality and reduces material waste.

-

Accessories: Cutting of leather and synthetic components.

-

Custom Designs: Enables intricate shapes and patterns.

Operational Guidelines and Maintenance Tips

To ensure long-term reliable operation and maintain cutting accuracy, proper machine operation and routine maintenance are crucial.

Operating Best Practices

-

Material Preparation: Ensure materials are clean and properly aligned before cutting.

-

Force Adjustment: Set the cutting force according to material thickness and toughness to avoid premature die wear.

-

Stroke Setting: Adjust stroke length for efficient cutting depth.

-

Swing Arm Use: Always use the swing arm to load and unload dies safely and efficiently.

-

Operator Safety: Use safety guards and emergency stops, and train operators on proper handling.

Routine Maintenance

-

Hydraulic Fluid: Regularly check and maintain hydraulic oil levels; the initial refueling volumes vary by model (36L for smaller models, 54L for the largest).

-

Lubrication: Keep moving parts lubricated to reduce friction and wear.

-

Cleaning: Remove dust, debris, and scrap materials after each shift to prevent jamming.

-

Inspection: Periodically inspect hoses, seals, and fittings for leaks or damage.

-

Calibration: Check cutting pressure and stroke adjustments to maintain consistent quality.

Why Choose Our Hydraulic Swing Arm Clicking Press?

Choosing the right die-cutting press can significantly impact production quality and efficiency. Here are some reasons why this Hydraulic Swing Arm Clicking Press stands out:

-

Proven Reliability: Engineered for durability and consistent performance in demanding industrial environments.

-

Versatility: Handles a wide variety of materials and cutting needs, reducing the need for multiple machines.

-

Ergonomic Design: Swing arm and easy controls enhance operator comfort and safety.

-

High Precision: Adjustable force and stroke length enable perfect cutting results.

-

Cost-Effective: Low maintenance and energy-efficient operation lower the total cost of ownership.

-

Comprehensive Support: Our expert team provides installation guidance, training, and ongoing service to maximize your machine’s uptime.

The Hydraulic Swing Arm Clicking Press Die Cutting Machine is an indispensable asset for industries requiring precision cutting of a variety of materials. From footwear to textiles, packaging to leather goods, this machine’s versatility, power, and ergonomic design empower manufacturers to achieve superior cutting accuracy, boost productivity, and maintain consistent product quality. Available in multiple models catering to different cutting forces and sizes, this machine offers a solution tailored to your specific production demands. Investing in this hydraulic press means investing in reliable, high-performance equipment that grows with your business.

No posts found