Hydraulic Arm Press Cutting Machine

The Hydraulic Swing Arm Clicking Press Die Cutting Machine is an indispensable piece of equipment for modern manufacturing processes involving non-metallic materials. Designed for precision, efficiency, and ease of use, this die-cutting machine is engineered to meet the demands of a broad range of industries. Whether you're working in footwear, leather goods, fashion accessories, packaging, automotive interiors, or crafting, this versatile tool delivers unmatched reliability and performance.

Premium Engineering for Superior Efficiency

At the core of the Hydraulic Swing Arm Clicking Press Die Cutting Machine is a powerful hydraulic system that ensures smooth and consistent cutting with every operation. This machine's advanced engineering and structural integrity result in optimal energy transmission and minimal waste. The swing arm design provides balanced pressure distribution, allowing for highly accurate cutting of single or multiple material layers. Efficiency is built into every detail. The innovative swing arm structure ensures that die placement and material alignment are quick and repeatable, drastically reducing setup time. With its ability to work quickly and precisely, the machine increases throughput and significantly reduces the cost-per-cut, which is critical for high-volume production environments. The design allows for high-speed operation with consistent pressure throughout the cutting process. This ensures that materials are cleanly and completely cut every time, without fraying or distortion. The press is equally suitable for soft, thick, or irregularly shaped materials, and it can accommodate complex die patterns with precision.

Safe, Intuitive Operation for All Skill Levels

Safety is a top priority in any industrial operation, and this machine incorporates thoughtful features that make it extremely user-friendly. The dual-hand control system prevents accidental activation and ensures that both of the operator’s hands are clear of the cutting area during operation. Additionally, the swing arm mechanism, powered by hydraulics, is designed to move smoothly without sudden motions, enhancing operator safety. The control interface is simple and intuitive, allowing even first-time users to become proficient within a short amount of time. It features clear, ergonomic controls that reduce fatigue during extended use. Whether operated by seasoned professionals or entry-level workers, the machine delivers consistent, professional results with minimal risk.

Long-Lasting Performance with Quality Components

Durability is a hallmark of the Hydraulic Swing Arm Clicking Press Die Cutting Machine. Every part is selected for long life and reliability under demanding production conditions. The machine frame is constructed from high-grade steel, precisely machined and reinforced to handle the stresses of continuous operation without deforming or degrading. Hydraulic components are sourced from internationally recognized suppliers, ensuring long service life and ease of replacement. Precision-ground surfaces and treated components minimize friction and wear, even under heavy workloads. The entire hydraulic circuit is sealed and pressure-regulated to prevent leaks and maintain consistent performance throughout the lifespan of the machine. This robust design means minimal maintenance downtime, reducing production interruptions and enhancing overall efficiency. When maintenance is required, it can be performed quickly and efficiently due to the modular structure and easily accessible components.

Hassle-Free Cleaning and Low Risk of Material Damage

Cleaning and maintenance have been streamlined to maximize uptime and maintain the highest quality standards. The open structure and thoughtful design ensure that the machine is easy to clean between jobs, which is especially important when working with sensitive materials or when changing between different color batches. A low operating noise and minimal vibration mean that the cutting action does not disturb delicate materials. The machine’s accuracy and gentle handling significantly reduce the chance of damage, scrapping, or rework, which is critical when working with high-cost materials or intricate patterns. The hydraulic control system and cutting head are designed to operate smoothly and precisely, even under variable load conditions. This guarantees a clean and professional finish for every cut, with negligible risk of tearing or distortion.

Versatile Applications Across Diverse Industries

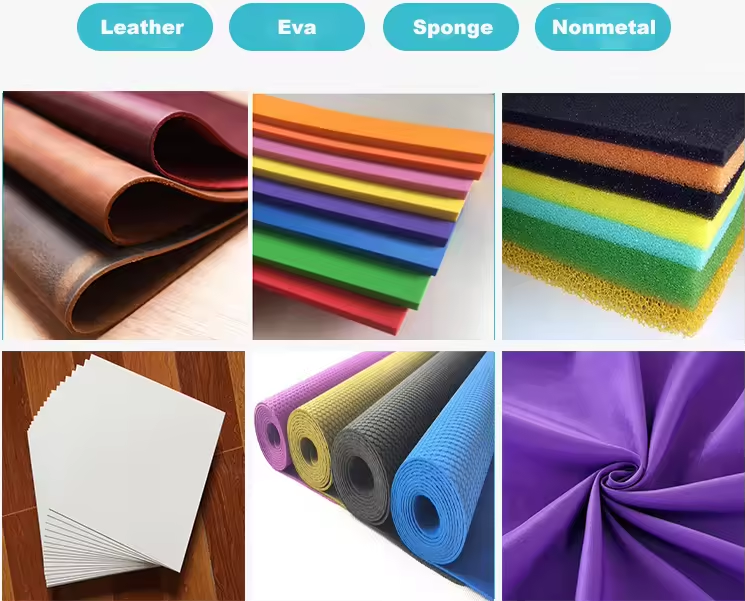

The Hydraulic Swing Arm Clicking Press Die Cutting Machine is engineered to meet the diverse needs of manufacturers across a wide range of industries. Its compatibility with various dies and materials allows for maximum flexibility and creativity.

-

Footwear Industry: Perfect for cutting leather, rubber, EVA, and fabric for uppers, soles, insoles, and decorative patches. Its speed and precision allow for mass production with minimal waste.

-

Leather Goods: Used for cutting handbags, wallets, belts, and other leather accessories. The precision of the machine ensures clean edges and uniform parts that are essential for premium-quality leather products.

-

Glove and Hat Manufacturing: This machine is adept at cutting multiple layers of thin or thick materials into the complex shapes required for gloves, hats, and other wearables.

-

Garment Accessories: Ideal for producing labels, emblems, badges, and trims from synthetic leather, fabric, felt, or foam.

-

Arts & Crafts: Suitable for die-cutting decorative elements, templates, and stencils from cardboard, plastic sheets, foam, or felt.

-

Packaging Industry: Efficiently cuts components for blister packs, cardboard inserts, plastic seals, and other packaging materials.

-

Automotive Supplies: Commonly used to produce parts like soundproof foam, insulation pads, upholstery components, and synthetic leather trims for vehicle interiors.

-

Pulled Flowers & Decorative Items: The fine cutting control makes it easy to produce intricate designs used in fashion or decor.

Technical Excellence with Advanced Hydraulics

The hydraulic system in this machine is built with industrial-grade components that provide fast response, consistent pressure, and long-term durability. The hydraulic motor and pump are finely tuned for optimal balance between power and energy efficiency. The cutting force is evenly distributed across the die surface, resulting in precise cutting across the entire work area. This even distribution reduces wear on cutting dies, lowers material stress, and minimizes the chance of uneven cuts, making it ideal for both standard shapes and custom designs. The swing arm moves on high-precision pivot points and is guided by hardened bearings and bushings that minimize mechanical play and ensure long-term stability.

Environmentally Conscious Design

Beyond performance, the Hydraulic Swing Arm Clicking Press Die Cutting Machine is built with sustainability in mind. The hydraulic circuit is energy-efficient, requiring less power per cut than many competing machines. Additionally, the reduced noise and vibration help maintain a healthier working environment for operators. The machine's minimal waste output and accurate cutting patterns contribute to material conservation, lowering both environmental impact and material costs. By delivering cleaner cuts and fewer errors, the machine supports a lean production environment where efficiency and environmental responsibility go hand in hand.

Cost-Effective Investment

Investing in the Hydraulic Swing Arm Clicking Press Die Cutting Machine is a smart move for any manufacturing business seeking to enhance productivity, ensure consistent product quality, and reduce labor costs. Its simple operation reduces the training burden on new employees, while its speed and precision lower operating costs over time. Because it can be used for a broad range of applications and materials, the machine provides excellent ROI across different projects and client demands. Its rugged build and high-quality components also translate to reduced long-term maintenance costs and extended service life. The reduced operator fatigue, enhanced safety, and minimized waste combine to make this machine a profitable addition to both small workshops and large-scale manufacturing lines.

Customization and Optional Features

To meet specific customer requirements, this machine can be fitted with additional features such as:

-

Digital stroke control for more precise depth settings

-

Custom die compatibility with different attachment mechanisms

-

Worktable modifications for specialized applications

-

Integrated feeding systems for roll or sheet materials

-

Automated die-change systems for high-mix, low-volume production

-

Enhanced safety enclosures or light curtains for extra protection

-

Programmable logic controllers (PLC) for automation integration

These options allow manufacturers to tailor the machine to their exact needs, making it even more versatile and efficient in specialized production environments.

The Hydraulic Swing Arm Clicking Press Die Cutting Machine combines modern technology, smart design, and rugged engineering to offer a cutting solution that is accurate, efficient, and versatile. With the ability to handle a vast range of materials and applications, this machine meets the rigorous demands of modern manufacturing while remaining accessible and safe for all levels of workers. Its exceptional build quality and user-centric design make it the perfect choice for businesses looking to improve productivity, reduce costs, and maintain the highest quality standards. From batch production to high-volume industrial cutting, the Hydraulic Swing Arm Clicking Press is the trusted workhorse that delivers every time.

No posts found