FOUR COLUMN HYDRAULIC VERTICAL-TYPE LEATHER MEASURING CUTTING MACHINE FOR PLASTIC EVA LEATHER SHOES MAKING TENGHONG TH-109

MACHINE NAME: FOUR COLUMN HYDRAULIC VERTICAL-TYPE LEATHER MEASURING CUTTING MACHINE FOR PLASTIC EVA LEATHER SHOES MAKING

MODEL NO: TH-109

BRAND: TENGHONG

FEATURES

- It is driven with belt transmission. With the transparent and separate roll, it can flatten the curled leather effectively and increase the measuring accuracy. Equipped with the advanced infra-red digital scanning device, so as to improve the measuring performance. If it is equipped with automatic printer (shown in the figure), it has the auto-printing function. Since its bringing into market, it has enjoyed a high reputation among shoe factories and leather products factories with small volume, easy operation single-phase power. Application: Used for shoe factory and each leather-product factories.

TECHNICAL PARAMETER

- Model : TH-109

- Dimension : 2330x900x1130mm

- Weight : 2000kg

- Cutting Force : 30-100 tons

- Main Motor Power(kW) : 2.2Kw

- Cutting Area : 610x1600mm

- Upper speed : 900(mm/s)

The Tenghong TH-109 Four Column Hydraulic Vertical-type Leather Measuring Cutting Machine is a state-of-the-art solution for precision cutting and accurate leather measurement, specifically engineered for modern shoe manufacturing and EVA plastic-based leather product production. Designed to accommodate the rigorous demands of industrial footwear and leather goods factories, this machine combines robust hydraulic technology, belt-driven mechanics, and intelligent scanning systems to deliver unmatched performance, accuracy, and operational efficiency. From its advanced belt-driven transmission system to its high-precision infrared digital scanning capabilities, the TH-109 is meticulously crafted to support the entire leather measuring and cutting process. Whether you are working with genuine leather, synthetic materials, or EVA components, this machine adapts to a variety of materials with ease and consistency. Let’s explore the full range of features and operational benefits that make the TH-109 an ideal solution for leather and EVA-based product manufacturing.

Key Features and Technical Innovations

Advanced Belt Transmission System

The TH-109 cutting machine is driven by a belt transmission system, offering smooth mechanical motion with reduced vibration and enhanced stability during operation. Belt-driven systems are well-known for their quiet operation, lower maintenance needs, and efficient energy use. This particular mechanism is optimized for precise linear motion, ensuring consistent pressure and motion during leather flattening and cutting. The belt transmission is carefully synchronized with the machine’s hydraulic components to deliver consistent, reliable performance even under heavy loads and extended production schedules.

Transparent and Separate Roll for Leather Flattening

One of the unique design elements of the TH-109 is its transparent and independent rolling mechanism, which is purpose-built to effectively flatten curled or uneven leather surfaces before cutting. This system ensures that all materials fed into the cutting zone are smooth, flat, and accurately aligned for measurement and processing. This pre-processing step significantly enhances the measuring accuracy, reducing material waste and ensuring that every piece cut meets strict quality and dimension standards. It also improves the effectiveness of the cutting force by ensuring uniform resistance throughout the leather or EVA sheet.

Infrared Digital Scanning for Precision Measurement

Equipped with an infrared digital scanning system, the TH-109 takes cutting precision to the next level. The scanning mechanism captures real-time data from the material surface, detecting texture, boundaries, and inconsistencies across the entire cutting area. This technology enables intelligent measurement and ensures each cut piece is optimized according to material characteristics. The digital scanning feature also allows for more advanced processing algorithms, automatically compensating for material deformities and ensuring highly consistent results. By combining mechanical accuracy with digital intelligence, this system addresses one of the most common challenges in leather cutting: unpredictable shape and material irregularities. The infrared scanning system transforms these challenges into opportunities for enhanced accuracy and productivity.

Optional Automatic Printer for Process Tracking

For manufacturers looking to further streamline their operations, the TH-109 can be optionally equipped with an automatic printing unit. This printer adds value by automatically marking or labeling the processed leather or EVA materials immediately after cutting. These markings can include batch numbers, production dates, reference lines, or part IDs, facilitating traceability and quality control within production workflows. The auto-printing function significantly improves shop floor logistics by ensuring each material segment is correctly identified and processed in subsequent stages of manufacturing. It is especially useful in multi-phase production environments where traceability and component classification are crucial.

Compact Footprint and Efficient Design

Despite its industrial-grade functionality, the TH-109 boasts a compact and ergonomic design. It fits comfortably into standard production spaces, making it ideal for both large-scale operations and smaller workshops. The single-phase power requirement makes it even more accessible, allowing deployment in a broader range of facilities without the need for industrial three-phase electrical infrastructure. This design consideration has contributed greatly to the machine’s popularity among shoe manufacturers and leather product factories, especially those looking to upgrade their cutting and measurement systems without overhauling their entire infrastructure.

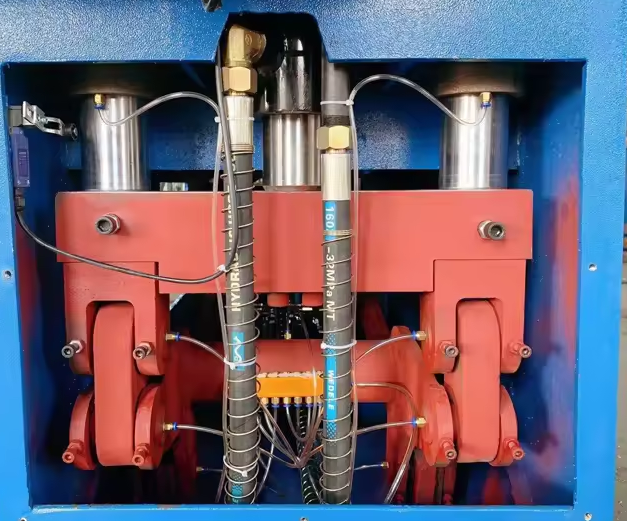

Robust Hydraulic Cutting System

At the heart of the TH-109 is its vertical-type four-column hydraulic press system. This configuration ensures high precision and stable cutting performance over long-term usage. Four-post hydraulic presses distribute cutting force evenly across the entire material surface, reducing mechanical stress and delivering consistent cuts even on tough or multi-layered materials. With an adjustable cutting force ranging from 30 to 100 tons, the machine offers flexibility for different material thicknesses and densities. Whether you're working with soft leather, rigid EVA sheets, or multi-layer composites, the hydraulic system adjusts accordingly to ensure optimal pressure and precision without compromising on speed or edge quality. This flexibility means that the machine is not only a good fit for shoe production but also suitable for a wide variety of applications across other leather goods industries, including bags, belts, wallets, upholstery, and more.

Application Scenarios and Industry Use

The TH-109 has quickly become a trusted choice among shoe manufacturers and leather goods producers, particularly those who prioritize accuracy, productivity, and low maintenance. Here's a closer look at the industries and applications where this machine excels:

Footwear Manufacturing

In shoe production, consistent material quality and precise cutting are critical for comfort, durability, and aesthetics. The TH-109 ensures that upper leather, lining, midsoles, and outsoles are all cut with exceptional uniformity, helping manufacturers reduce wastage and rework. The flattening system is especially useful when dealing with curled leather or EVA foam, which can otherwise lead to measurement errors and misalignment during assembly.

Leather Accessories Production

Manufacturers of leather goods like handbags, belts, wallets, and pouches benefit from the machine’s infrared scanning and adjustable pressure system, which allows for precision cutting of detailed shapes and logos while preserving material integrity. The optional printer provides a critical advantage here, enabling traceability and labeling in small-batch or bespoke production runs.

Upholstery and Automotive Applications

For industries that require cutting large pieces of leather or synthetic alternatives, such as automotive interiors or home furniture, the machine’s large-format cutting area and powerful hydraulic press ensure efficient handling of thick or oversized materials.

Operational Advantages

Easy to Use and Maintain

Thanks to its user-friendly interface and simplified mechanical layout, the TH-109 is easy to operate with minimal training. Operators can quickly load materials, initiate scans, and execute cuts with straightforward controls. Routine maintenance is also simplified. The belt transmission reduces wear and tear on motorized components, while the modular hydraulic system allows for easy diagnostics and part replacement.

Energy-Efficient Operation

Despite its power, the machine is designed for energy efficiency, operating comfortably on 2.2 kW of power. The integration of smart scanning and precision cutting means fewer mistakes, less material waste, and shorter operating times, all contributing to lower energy consumption over time. This makes it an environmentally conscious investment, especially for companies seeking to reduce their carbon footprint without sacrificing performance.

Enhanced Safety Features

The TH-109 is equipped with multiple safety systems, including emergency stops, overload protection, and secure enclosure designs to protect operators from potential hazards. The machine also includes an intelligent control system that halts operation if an irregularity is detected in material positioning or scanning results. These safety elements ensure a secure work environment, supporting compliance with international factory standards and reducing the likelihood of workplace injuries.

Summary of Performance Highlights

-

Cutting Area: With a spacious cutting area of 610 mm by 1600 mm, the machine can accommodate both large and small materials, increasing its operational versatility.

-

High Speed: Featuring an upper-speed performance of 900 mm/s, the machine ensures rapid throughput, making it suitable for both mass production and custom runs.

-

Durability: Weighing 2000 kg, the TH-109 is constructed with a solid frame and industrial-grade materials, ensuring stability and durability even in the most demanding production environments.

Customer Satisfaction and Market Feedback

Since its market release, the TH-109 Four Column Hydraulic Cutting Machine has received widespread acclaim from factories around the world. Its combination of high precision, low power consumption, and ease of use has made it a favorite among production managers, machine operators, and factory owners alike. Many customers cite the flattening roll and digital scanning as transformative features that significantly improved their cutting consistency and reduced material loss. The optional automatic printer has also proven to be a highly valued addition, helping streamline inventory management and quality assurance processes. The machine has particularly shone in markets where material consistency, production speed, and reliability are top priorities, including Southeast Asia, Europe, and South America.

The Tenghong TH-109 Four Column Hydraulic Vertical-type Leather Measuring Cutting Machine is a comprehensive, reliable, and advanced solution for manufacturers of leather and EVA-based products. It's thoughtful engineering from the belt-driven mechanism and flattening rollers to the infrared scanning and powerful hydraulic press that addresses every challenge faced by modern cutting operations. Whether you are running a full-scale factory or a specialized boutique operation, the TH-109 delivers professional-grade performance with unmatched simplicity and efficiency. For businesses aiming to boost productivity, reduce waste, and elevate product quality, this machine stands out as a valuable investment.

No posts found